conor1n

Member

- Messages

- 566

- Location

- London/Ireland

Hello all,

(I am talking about the brass fitting that screws into the tank)

Quick one here. On my compressor there is a slight leak on the connection that threads directly into the tank and received the air from the motor head..

Part of the issue is the considering the solid pipe that feeds into it the fitting needs to stop at a specified position, meaning I can't just crank it until sealed.

I tried to fix it by removing the fitting and taping the threads with PTFE. But then when I closed it up again, the leak was worse than before. (Tested with soapy water).

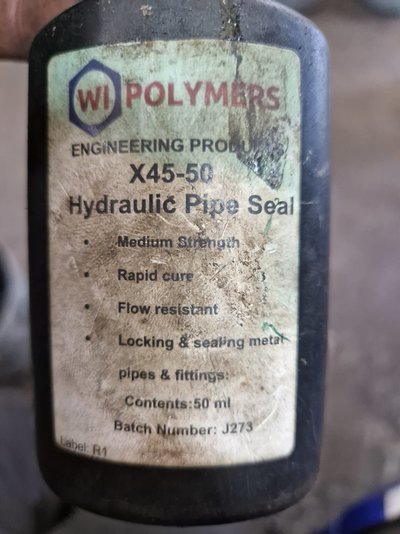

When I removed the fitting I noticed some kind of compound in the threads that went hard. Was that thread locker, or is there some kind of compound I can get to seal the threads? Or is it a case of just using more PTFE?

My OCD is killing me when I know this is leaking and it having to run every time I turn it on.

Thanks a lot guys

Conor

(I am talking about the brass fitting that screws into the tank)

Quick one here. On my compressor there is a slight leak on the connection that threads directly into the tank and received the air from the motor head..

Part of the issue is the considering the solid pipe that feeds into it the fitting needs to stop at a specified position, meaning I can't just crank it until sealed.

I tried to fix it by removing the fitting and taping the threads with PTFE. But then when I closed it up again, the leak was worse than before. (Tested with soapy water).

When I removed the fitting I noticed some kind of compound in the threads that went hard. Was that thread locker, or is there some kind of compound I can get to seal the threads? Or is it a case of just using more PTFE?

My OCD is killing me when I know this is leaking and it having to run every time I turn it on.

Thanks a lot guys

Conor