Hi All,

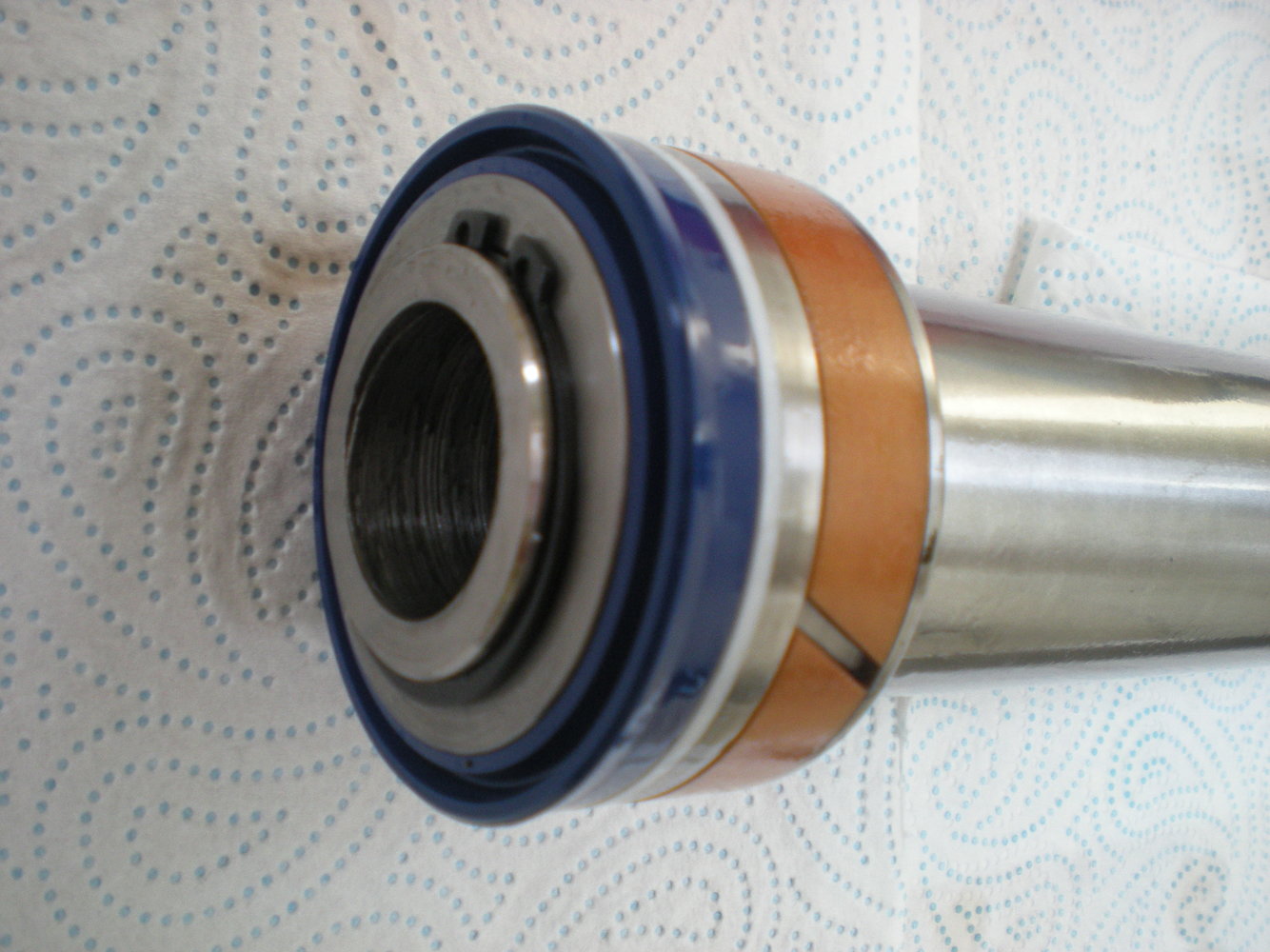

I bought a no-name 30 ton hydraulic cylinder a while back with which to build a press. I decided to tear down the cylinder for a couple of reasons and I made one or two what I hope are improvements. The cylinder is pictured apart below in case it's useful - the pictures show the modified version. The mods were:

1. Cut a wide groove in the piston and fit a guide ring/wear ring to keep the piston away from the walls - this is the brown band on the piston.

2. Add a bronze sleeve to the end ring of the cylinder so that the piston rubs the bronze and not steel as it exits the cylinder

3. Shorten the return spring.

The guide ring is on the dry side of the piston seal which isn't ideal, but I'm hoping there's generally going to be some oil film.

Generally the cylinder is well made considering the price. I'm not convinced I don't have a tiny leak somewhere after re-assembly, based on a very slow pressure drop when left standing for a while, but nothing worth worrying about. I'm running the cylinder at a max of 500 bar by choice so I'm de-rating - at 500 bar and a 75mm diameter, I make that 22.5 metric ton force.

I bought a no-name 30 ton hydraulic cylinder a while back with which to build a press. I decided to tear down the cylinder for a couple of reasons and I made one or two what I hope are improvements. The cylinder is pictured apart below in case it's useful - the pictures show the modified version. The mods were:

1. Cut a wide groove in the piston and fit a guide ring/wear ring to keep the piston away from the walls - this is the brown band on the piston.

2. Add a bronze sleeve to the end ring of the cylinder so that the piston rubs the bronze and not steel as it exits the cylinder

3. Shorten the return spring.

The guide ring is on the dry side of the piston seal which isn't ideal, but I'm hoping there's generally going to be some oil film.

Generally the cylinder is well made considering the price. I'm not convinced I don't have a tiny leak somewhere after re-assembly, based on a very slow pressure drop when left standing for a while, but nothing worth worrying about. I'm running the cylinder at a max of 500 bar by choice so I'm de-rating - at 500 bar and a 75mm diameter, I make that 22.5 metric ton force.