johnrev

Member

- Messages

- 225

- Location

- Norfolk, UK

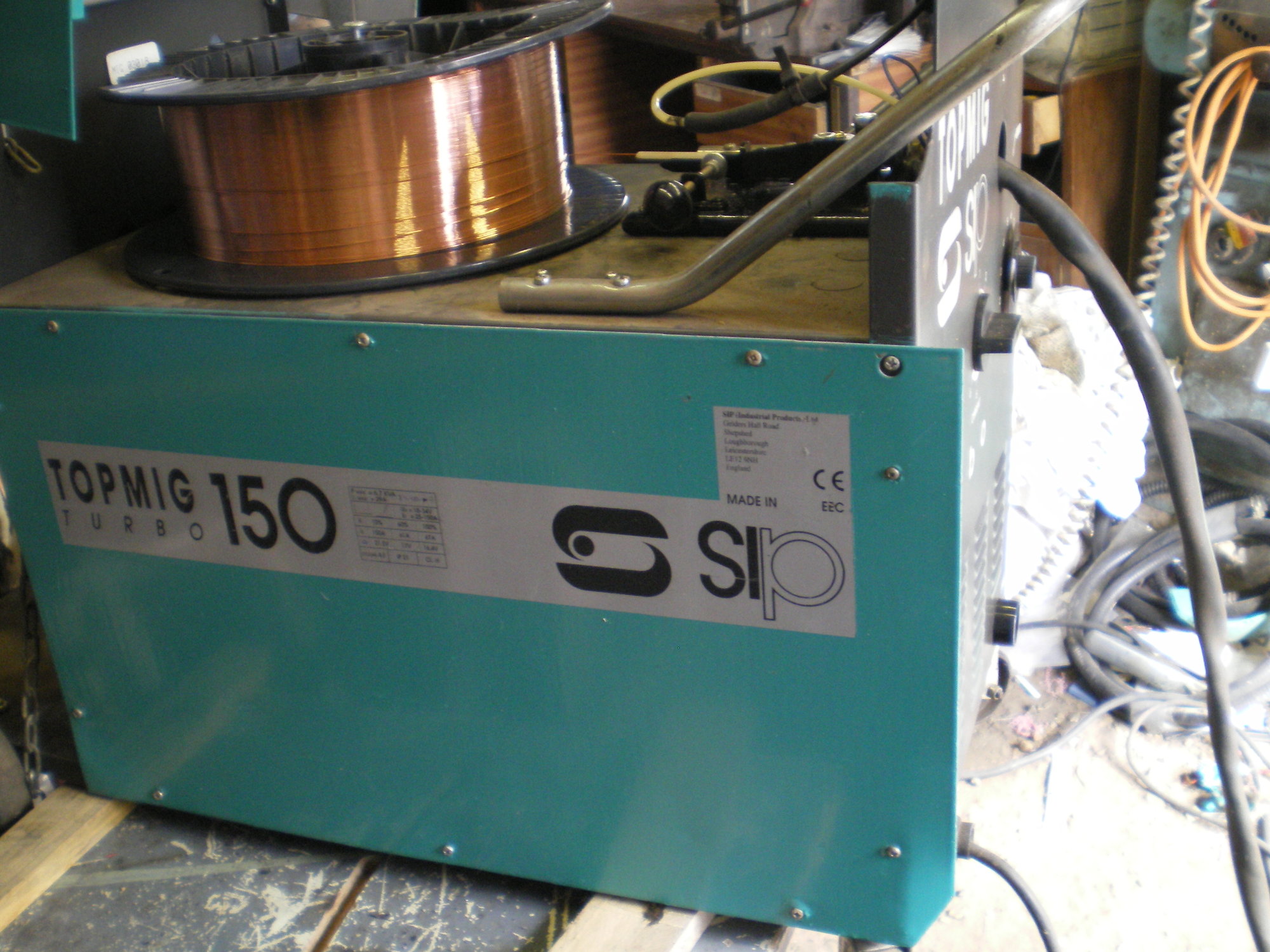

Yes I am a bit barmy but I really do like the old big SIPs-Topmig, Autoplus etc. Not because they are great welders or well made or high performance - they are none of these things. I like them because they are simple and cheap to buy when they are a few years old and being SIPs are probably playing up. The cases are huge and the innards are not so there's lots of room inside for adding 'improvements' and most of the improvements are a DIY type job if you have a bit of time and you take the trouble to read these forums and gain the knowledge you need.

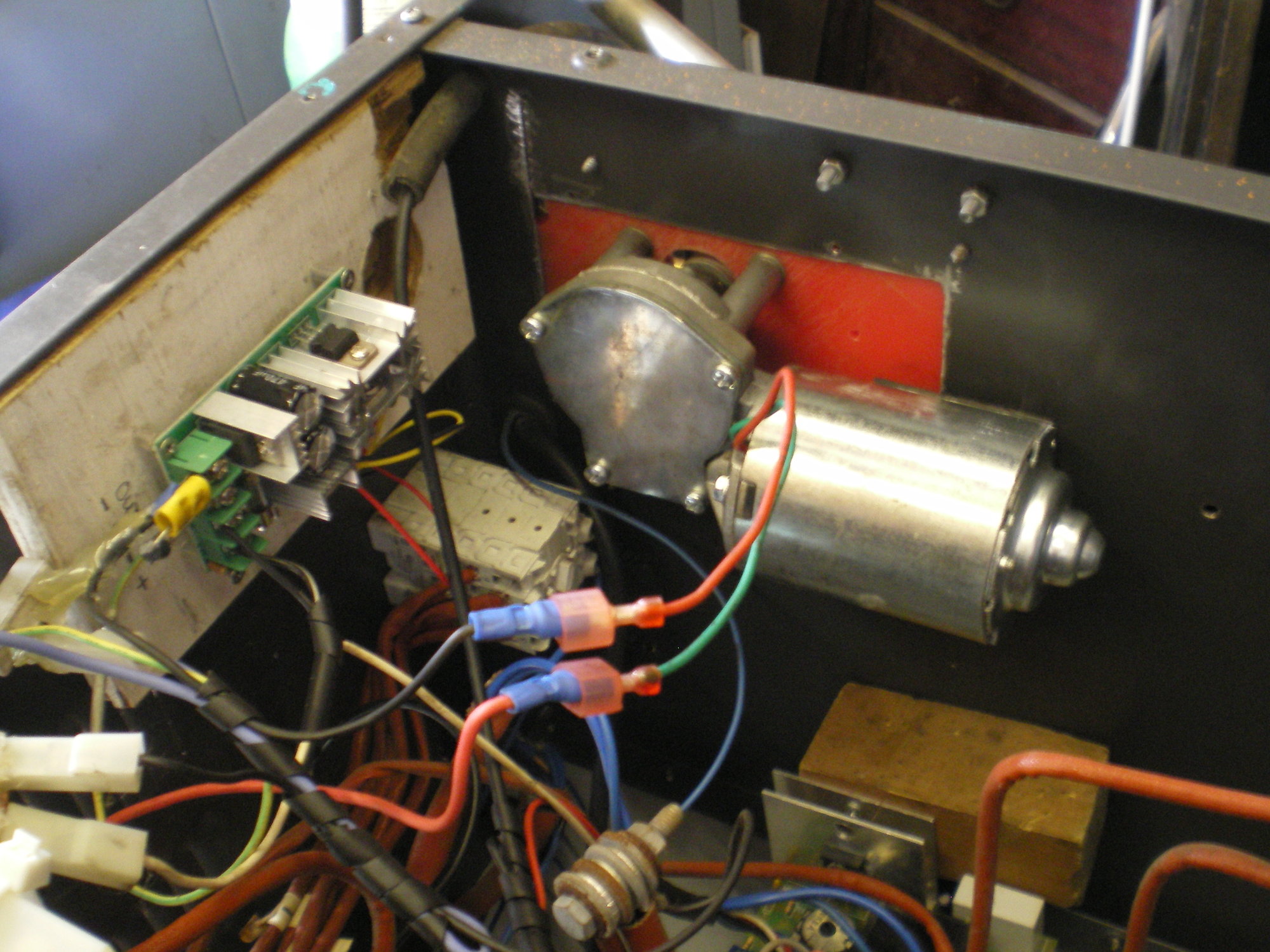

I bought an Autoplus 150 a while ago and did the seperate wire feed PSU and pulse width modulation motor controller mods. It now performs very well and is my go-to machine.

I recently bought a Topmig 150 and did the same again and it did work OKish but the wirefeeder is a joke on these things. The Autoplus has the nice big wiper motor type feed with strong and accurate roller system and is a rock steady feed system. The Topmig has a thoroughly ridiculous toy motor with plastic gears in a floppy plastic casing with no bearings so everything is sloppy and feeding the wire in any useable way seems to happen purely by chance. Sure the 'Migwelding brace' does help and makes the unuseable slightly better but it's still a dogs dinner of a system and inspires no confidence at all.

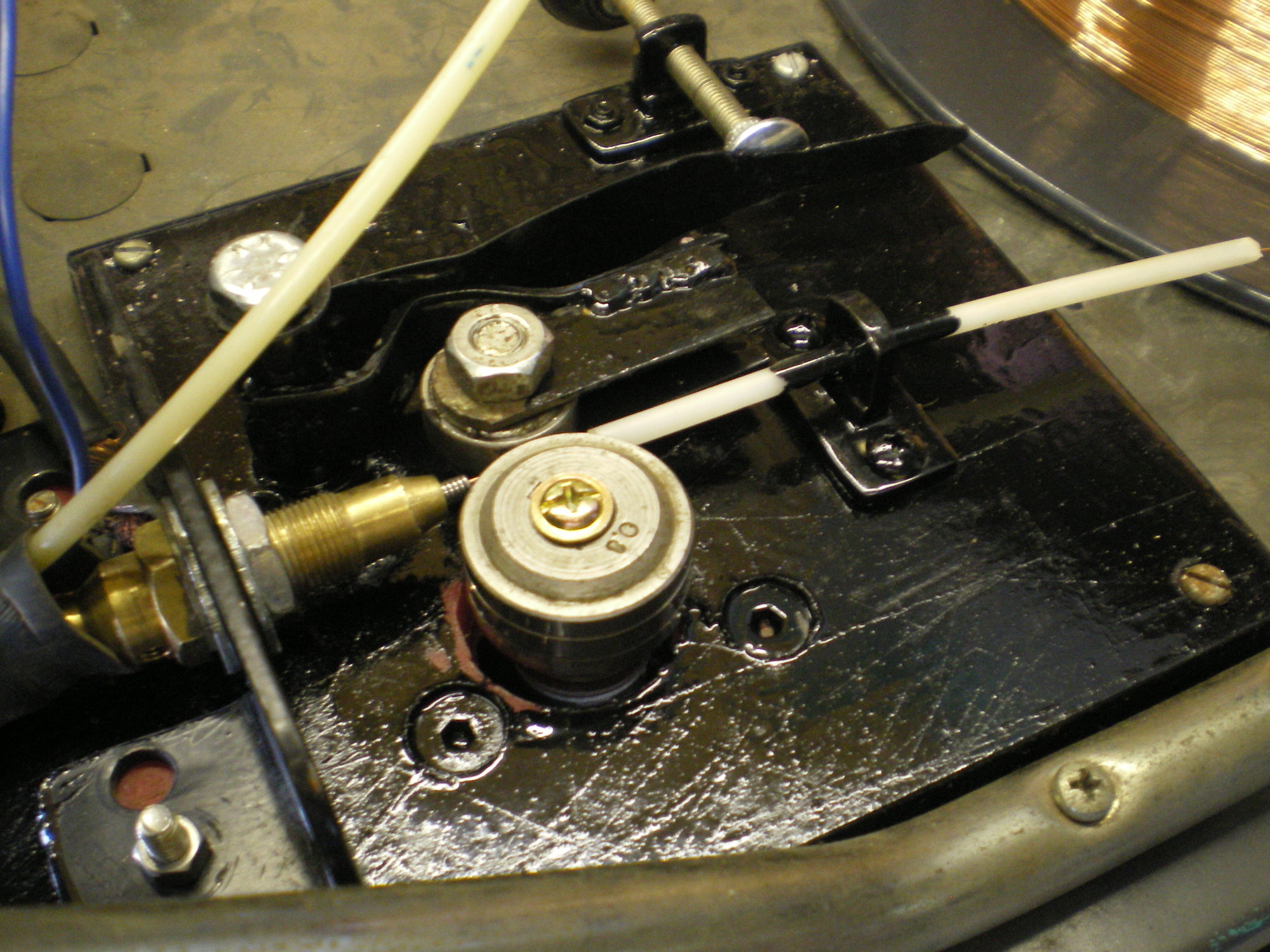

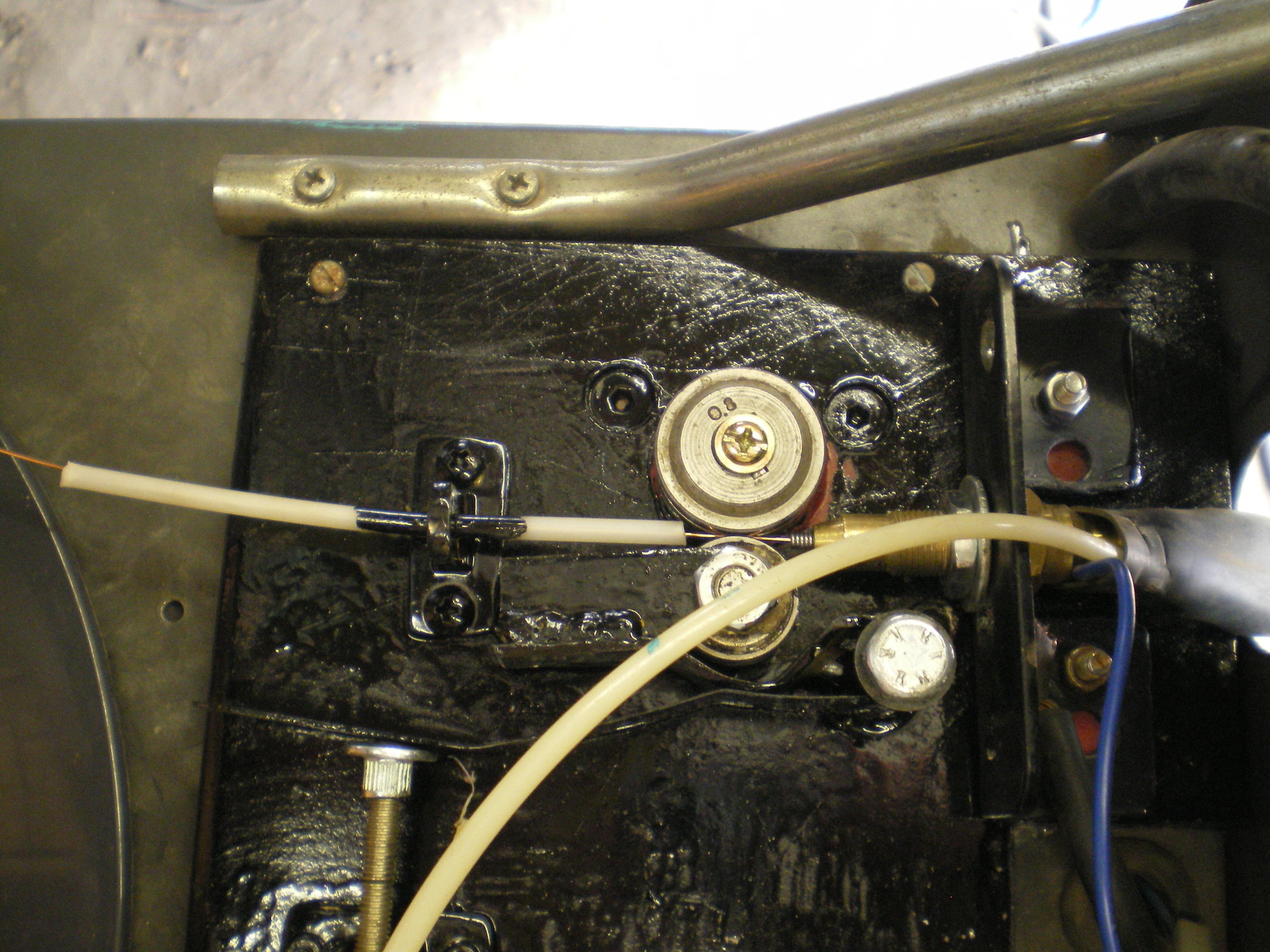

So I decided that while I am in forced isolation at the moment I'd have a go at making a new feeder. I'm a bit of a collector and have accumulated a few different motor/gearbox combinations since I started playing with SIPs a few years ago 'just in case'. One of them looked to be a good candidate and so the feeder in the pics was put together.

Built on an industrial kitchen cutting board (shenion idea I think) and using a spare feed roller which just happened to fit the output shaft it isn't pretty but it works very well indeed. Smooth and powerful and glitch-free. I am pleased as punch.

A quick coat of black as it was a gaudy bright red board and also

gave the machine a coat of my favourite turquoise gloss and it's all good.

gave the machine a coat of my favourite turquoise gloss and it's all good.

I had intended to keep the Autoplus and sell the Topmig but now I'm thinking I may change my plans.

I bought an Autoplus 150 a while ago and did the seperate wire feed PSU and pulse width modulation motor controller mods. It now performs very well and is my go-to machine.

I recently bought a Topmig 150 and did the same again and it did work OKish but the wirefeeder is a joke on these things. The Autoplus has the nice big wiper motor type feed with strong and accurate roller system and is a rock steady feed system. The Topmig has a thoroughly ridiculous toy motor with plastic gears in a floppy plastic casing with no bearings so everything is sloppy and feeding the wire in any useable way seems to happen purely by chance. Sure the 'Migwelding brace' does help and makes the unuseable slightly better but it's still a dogs dinner of a system and inspires no confidence at all.

So I decided that while I am in forced isolation at the moment I'd have a go at making a new feeder. I'm a bit of a collector and have accumulated a few different motor/gearbox combinations since I started playing with SIPs a few years ago 'just in case'. One of them looked to be a good candidate and so the feeder in the pics was put together.

Built on an industrial kitchen cutting board (shenion idea I think) and using a spare feed roller which just happened to fit the output shaft it isn't pretty but it works very well indeed. Smooth and powerful and glitch-free. I am pleased as punch.

A quick coat of black as it was a gaudy bright red board and also

I had intended to keep the Autoplus and sell the Topmig but now I'm thinking I may change my plans.