skotl

Forum Supporter

- Messages

- 10,410

- Location

- Edinburgh, UK

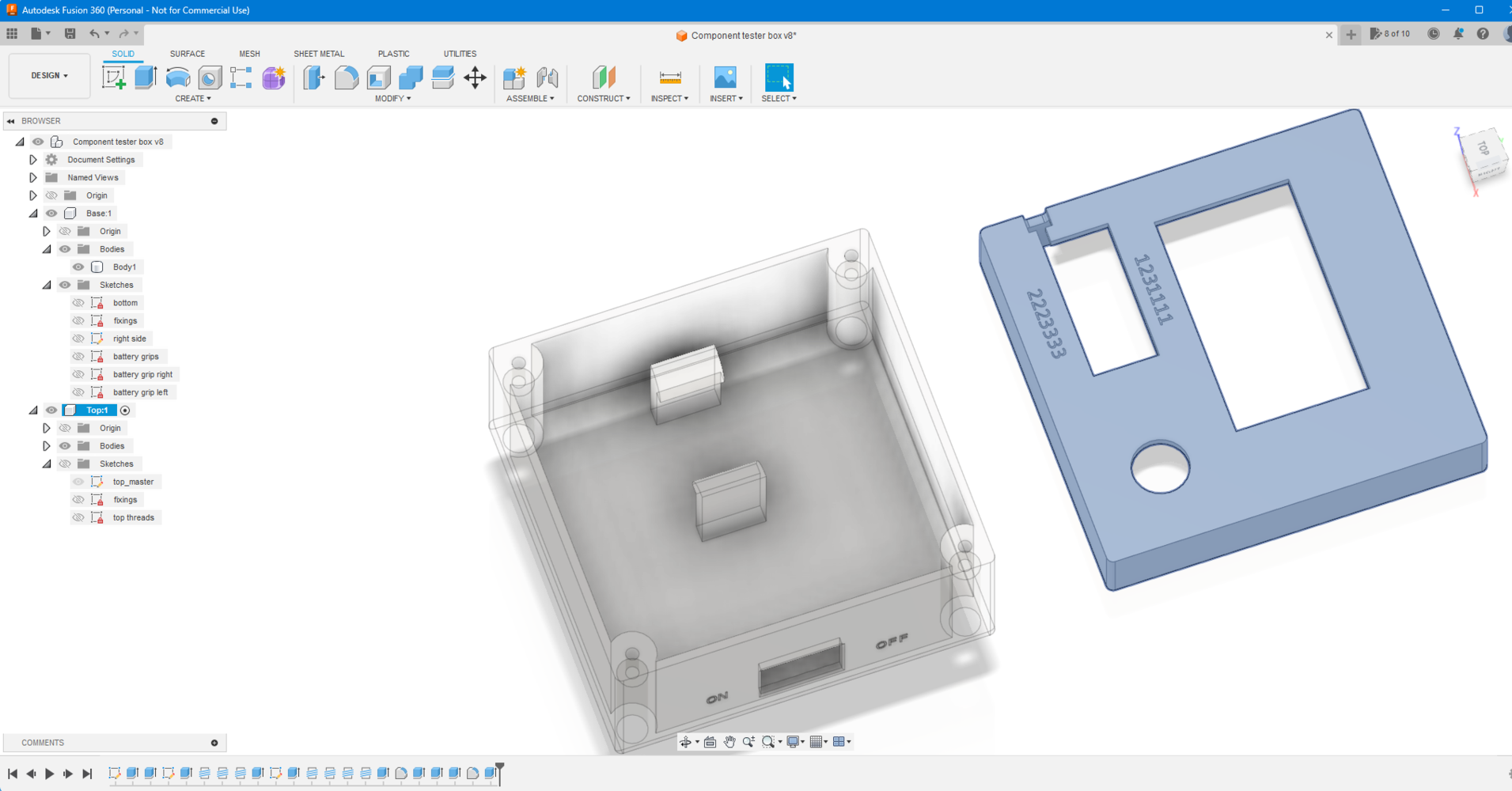

Making a case for a components tester, which is surprisingly complex given the precise measurements of component cutouts, standoff heights, etc....

...and I decided to try a slightly different approach, which is almost certainly something the old hands will laugh at (and presumably also do).

It's all about measures!

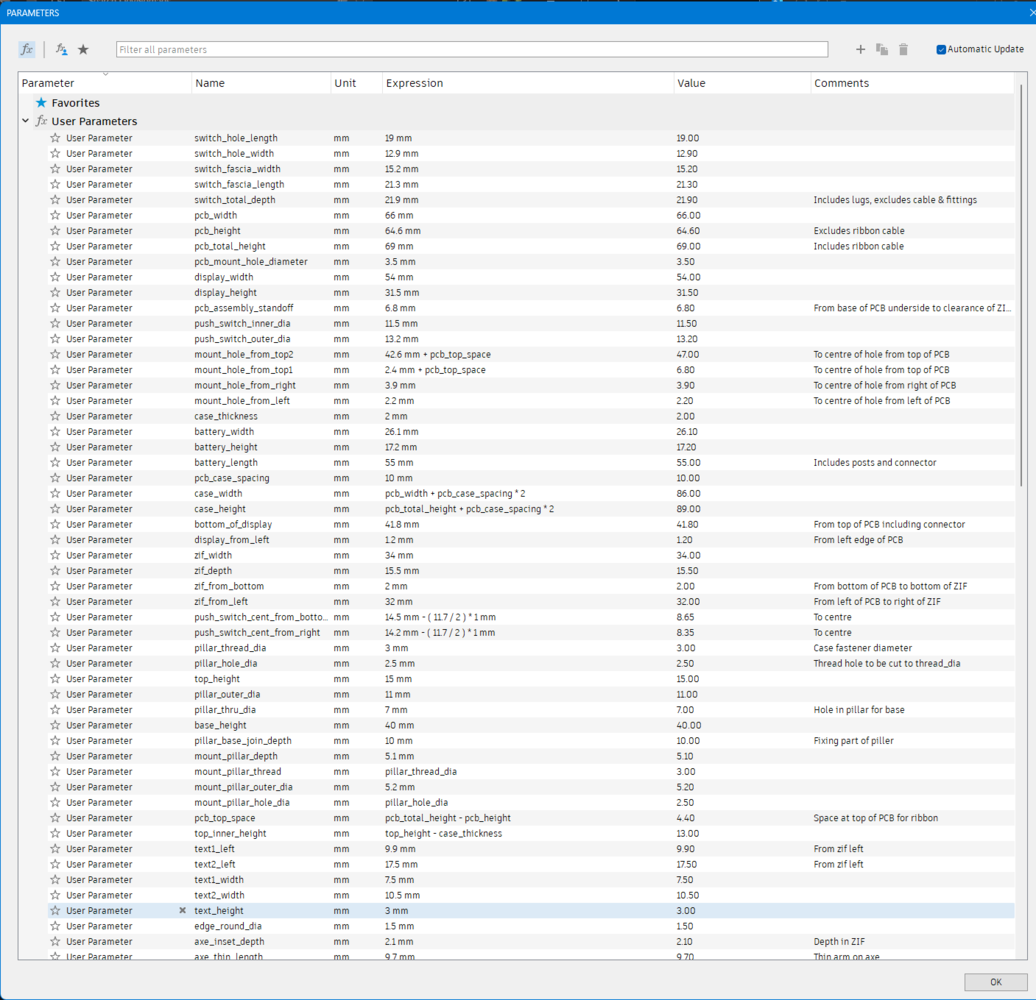

I spent an hour with a micrometer measuring the circuit board, a PP3 battery and a switch and painstakingly putting them all into F360's parameters:

And then I drew the sketches, extruded, created additional sketches, etc. all referencing the parameters off the bat - there's not a single hard-coded size in the drawing.

Then when it came to printing up the prototypes it was really easy to make the tiny adjustments needed, and extremely satisfying to watch the components redraw themselves correctly!

So my revelation (and Fusion 360 / CAD / 3D Printing) tip of the day is: for anything that's not super basic, spend the time to measure and record all of the parameters first. Second tip - base other parameters on earlier parameters.

Suppose it's just like metalworking, carpentry and any kind of making: the more time spent measuring and planning, the less time spent on rework!

...and I decided to try a slightly different approach, which is almost certainly something the old hands will laugh at (and presumably also do).

It's all about measures!

I spent an hour with a micrometer measuring the circuit board, a PP3 battery and a switch and painstakingly putting them all into F360's parameters:

And then I drew the sketches, extruded, created additional sketches, etc. all referencing the parameters off the bat - there's not a single hard-coded size in the drawing.

Then when it came to printing up the prototypes it was really easy to make the tiny adjustments needed, and extremely satisfying to watch the components redraw themselves correctly!

So my revelation (and Fusion 360 / CAD / 3D Printing) tip of the day is: for anything that's not super basic, spend the time to measure and record all of the parameters first. Second tip - base other parameters on earlier parameters.

Suppose it's just like metalworking, carpentry and any kind of making: the more time spent measuring and planning, the less time spent on rework!