JMS1972

Member

- Messages

- 1,208

- Location

- NW Leicestershire, UK

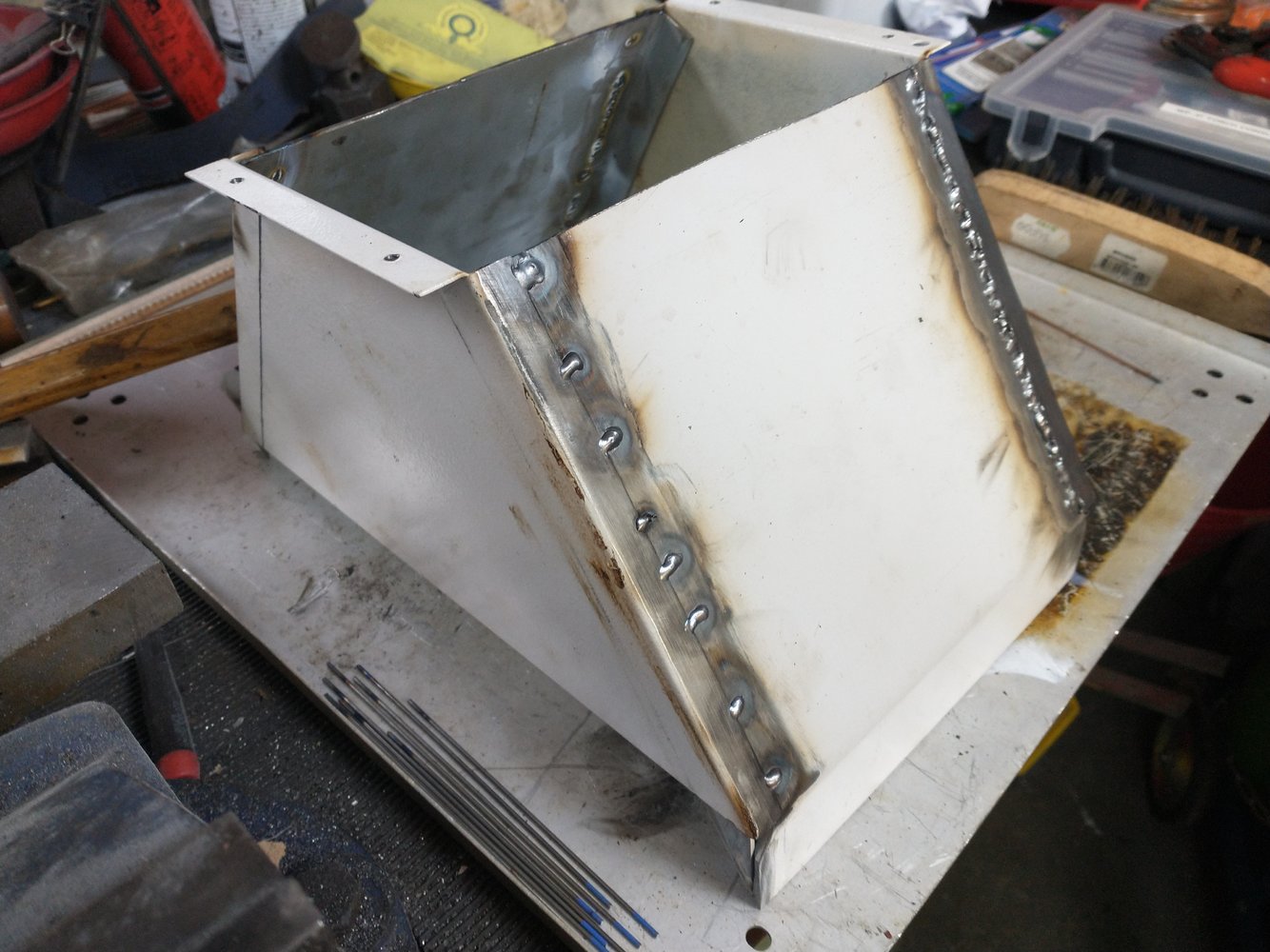

I'm lashing up a crud collector for my T&C grinder out if bits of metal I have lying around.

The two parts I'm welding are 1mm and 2mm mild steel

I'm using 1.6mm Tungstens and filler rods and 55Amps with 2second post flow.

Tack welds are going okay starting from the 2mm side.

Seam welds as you'd expect I'm tending to burn back the 1mm.

Obviously I need a lot more practice (generally) any tips on welding different sized stuff?

It's starting to take shape note stack of dipped Tungstens that need sharpening.

thanks.

The two parts I'm welding are 1mm and 2mm mild steel

I'm using 1.6mm Tungstens and filler rods and 55Amps with 2second post flow.

Tack welds are going okay starting from the 2mm side.

Seam welds as you'd expect I'm tending to burn back the 1mm.

Obviously I need a lot more practice (generally) any tips on welding different sized stuff?

It's starting to take shape note stack of dipped Tungstens that need sharpening.

thanks.