greyshirtguy

Persistent Learner

- Messages

- 150

Although it's not a very inspiring project - I figured I would run this thread to which will detail my current project of rebuilding a small kit storage shed that was torn down in a storm last year.

When we bought our new house it had this 6x3 metre kit garden shed in the back yard:

It was just sitting on the ground (no slab) and had a few pegs to "hold" it down.

The ground often got very wet in winter - which limited what I could safely store in there (mostly fire wood raised off the ground) I had planned to do a concrete slab and finally use it for real storage (freeing up our car garage)..

But along came a storm one day and...

Most of the damage was to the "channel" (or c-section) that ran along the edge of the flimsy wall panels to give them structural rigidty. Also, one part of a wall section is a bit too dented to provide the support it should.

Of course, because it's just a cheap kit shed, it has proven hard to get parts to repair it second hand - I've been looking on and off for 6 months now.

The new parts can be bought for it but they will cost a surprising chunk of the replacement cost (a new replacement is "only" about $1400 AUD - which is a bit too much for my budget in the near future....)

So my current idea is to build a relatively sturdy frame on a slab and rebuild the shed around that frame. The frame doesnt have to provide 100% of the structual integrity - the shed will provide some support even with it's slighty dented wall section and broken channel sections (that I will repair with small "joiner" sections)

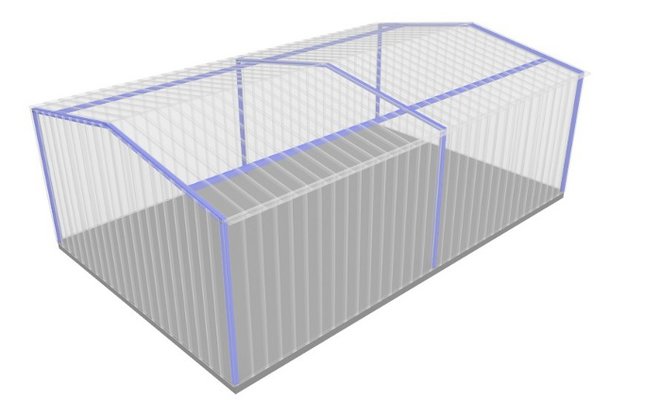

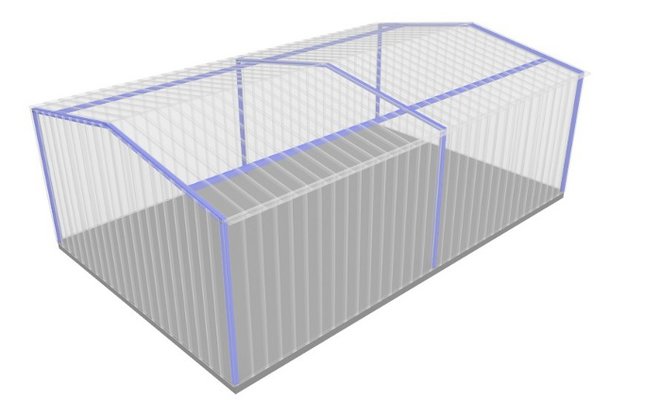

The cost for some steel (50x50 RHS in 1.6mm thicknes) to build a frame (as per design below) is only about $180 - and of-course I get to enjoy welding it together!!!

I have a 2m length of 50x50x1.6RHS and tried to get a "rough feel" for it's strength by standing in the middle of it (ends supported off the floor) to see how far it would dip under my 85KG - I was surpised by it's strength - it only dipped about 25mm and sprung back. It certainly gave me impression it would be strong enough for my frame design (the lengths in the "trusses" are <2m and between the trusses are < 3m)

I will also probably X brace both wall sections at the "back".

I will also take advantage on another smaller (but slightly wider) shed on a proper slab - by rebuilding onto the end of it - and make one "large" shed.

This will mean I'll need to make the shed a little wider (by using the left-over cladding after "joining the two ends")

So here is the simple design I am thinking of making.....

I'll post updates as I make any progress or design changes (this will be slow as I work in my rather limited spare time)

Oh, and if you have read this far and have any tips/advice - then please feel free to say so!

When we bought our new house it had this 6x3 metre kit garden shed in the back yard:

It was just sitting on the ground (no slab) and had a few pegs to "hold" it down.

The ground often got very wet in winter - which limited what I could safely store in there (mostly fire wood raised off the ground) I had planned to do a concrete slab and finally use it for real storage (freeing up our car garage)..

But along came a storm one day and...

Most of the damage was to the "channel" (or c-section) that ran along the edge of the flimsy wall panels to give them structural rigidty. Also, one part of a wall section is a bit too dented to provide the support it should.

Of course, because it's just a cheap kit shed, it has proven hard to get parts to repair it second hand - I've been looking on and off for 6 months now.

The new parts can be bought for it but they will cost a surprising chunk of the replacement cost (a new replacement is "only" about $1400 AUD - which is a bit too much for my budget in the near future....)

So my current idea is to build a relatively sturdy frame on a slab and rebuild the shed around that frame. The frame doesnt have to provide 100% of the structual integrity - the shed will provide some support even with it's slighty dented wall section and broken channel sections (that I will repair with small "joiner" sections)

The cost for some steel (50x50 RHS in 1.6mm thicknes) to build a frame (as per design below) is only about $180 - and of-course I get to enjoy welding it together!!!

I have a 2m length of 50x50x1.6RHS and tried to get a "rough feel" for it's strength by standing in the middle of it (ends supported off the floor) to see how far it would dip under my 85KG - I was surpised by it's strength - it only dipped about 25mm and sprung back. It certainly gave me impression it would be strong enough for my frame design (the lengths in the "trusses" are <2m and between the trusses are < 3m)

I will also probably X brace both wall sections at the "back".

I will also take advantage on another smaller (but slightly wider) shed on a proper slab - by rebuilding onto the end of it - and make one "large" shed.

This will mean I'll need to make the shed a little wider (by using the left-over cladding after "joining the two ends")

So here is the simple design I am thinking of making.....

I'll post updates as I make any progress or design changes (this will be slow as I work in my rather limited spare time)

Oh, and if you have read this far and have any tips/advice - then please feel free to say so!