Brain_stew

Member

- Messages

- 30

Hi Guys and Girls,

Im Graham been a long time lurker on here, and have to say some of you have some amazing skills from both fabrication and welding.

I've done the odd bit of welding over the past year or so, on car sills, work bench's and im currently working on a Bead Braker for some friends that do banger racing (very slow progress)

I've preiously owned a wolf weld 120 gasless (fried the circuit board) so i decided i'd go and pick myself up a Lincholn Powertec 161c this gives me the chance to work using both fluxed cored and gas. also have a little 80amp Arc welder laying about. i'm self taught in both area's so i dont have the greatest of welds but i am getting better each time.

This site has been a great help so far for getting the right power settings for the thickness of the metals i've been working with.#

**EDIT**

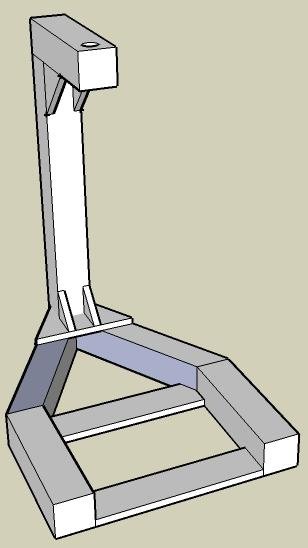

attached is a design view of the Bead Braker, its a bit over enginerred but with the amount of abuse it will be given it should hold up and do the job.

Im Graham been a long time lurker on here, and have to say some of you have some amazing skills from both fabrication and welding.

I've done the odd bit of welding over the past year or so, on car sills, work bench's and im currently working on a Bead Braker for some friends that do banger racing (very slow progress)

I've preiously owned a wolf weld 120 gasless (fried the circuit board) so i decided i'd go and pick myself up a Lincholn Powertec 161c this gives me the chance to work using both fluxed cored and gas. also have a little 80amp Arc welder laying about. i'm self taught in both area's so i dont have the greatest of welds but i am getting better each time.

This site has been a great help so far for getting the right power settings for the thickness of the metals i've been working with.#

**EDIT**

attached is a design view of the Bead Braker, its a bit over enginerred but with the amount of abuse it will be given it should hold up and do the job.