- Messages

- 14,511

- Location

- UK

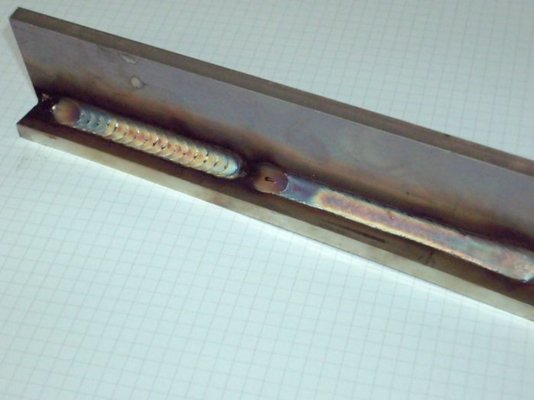

We recently purchased a Lorch S8 from Matt1978. Its a 500 amp job, with Speed Up, Speed Arc and Speed Pulse software installed. Nice machine. Speed Arc and Speed Up are the two settings that are most used. Speed Up is very impressive, allowing you to do a vertical-up weld without having to do the traditional Xmas tree weave. Its almost the same motion as a vertical-down, the welding set does the rest for you. The machine has dramatically reduced welding time, and clean up time. Produces neat and tidy spatter-free welds eliminating post weld clean up. There is no need on this machine to set volts and wire speed (and messing about testing your settings before welding). Simply tell it what mode you want, what gas, what wire size and what thickness you are welding and the machine sets itself up. The settings can be fine tuned by the operator to suit personal preference. A nice touch is the Powermaster torch. The settings can be controlled from the torch to save going back to the machine each time you change position or material thickness.

This pallet of beams was welded-up in 1 hour dead. With a transformer type machine it would have taken nearer 2 hours.

Yer need to watch for bare patches of skin. Seems a much more intense arc - lots of red patches where the light has crept in The settings seem top end for power. Not a problem to me as i like to weld as hot as i can

The settings seem top end for power. Not a problem to me as i like to weld as hot as i can

This is probably not the best sales pitch, and i'm not as good a salesman as Matt, but all the same, a real nice machine. Matt demo'd the machine and spent a good while here showing everyone what it could do. Makes the difference. The novelty of being able to pre-programme settings and name them seems to be wearing off thank god. Each welder can have their own menu with different job names in. Every time i come to use it though the language is always in Polish.

I forgot to take a picture of the earth clamp. Seriously over engineered. Its massive. Takes two hands to open it; it could probably cope with 1000a through it.

Seriously over engineered. Its massive. Takes two hands to open it; it could probably cope with 1000a through it.  Can't clamp it to anything delicate - it would crush it

Can't clamp it to anything delicate - it would crush it

This pallet of beams was welded-up in 1 hour dead. With a transformer type machine it would have taken nearer 2 hours.

Yer need to watch for bare patches of skin. Seems a much more intense arc - lots of red patches where the light has crept in

The settings seem top end for power. Not a problem to me as i like to weld as hot as i can

The settings seem top end for power. Not a problem to me as i like to weld as hot as i can

This is probably not the best sales pitch, and i'm not as good a salesman as Matt, but all the same, a real nice machine. Matt demo'd the machine and spent a good while here showing everyone what it could do. Makes the difference. The novelty of being able to pre-programme settings and name them seems to be wearing off thank god. Each welder can have their own menu with different job names in. Every time i come to use it though the language is always in Polish.

I forgot to take a picture of the earth clamp.

Seriously over engineered. Its massive. Takes two hands to open it; it could probably cope with 1000a through it.

Seriously over engineered. Its massive. Takes two hands to open it; it could probably cope with 1000a through it.

![SpeedArc Steel & SpeedPulse Stainless[1].JPG](/forum/data/attachments/16/16045-44331209b4c5aacf0e7df0851fc1b5bd.jpg)