Memmeddu

Member

- Messages

- 4,753

- Location

- Italia Sardegna

Hi everyone as for everything I want try to make it happens that I found a bargain down the road

(Engine driven welder I was putting the things together when I found my genset or the engine driven air compressor which I could get one soon but it's not sure yet )

Back to the topic the story repeated I was making a magnetic stand when I was reading a Facebook group about welding hobby

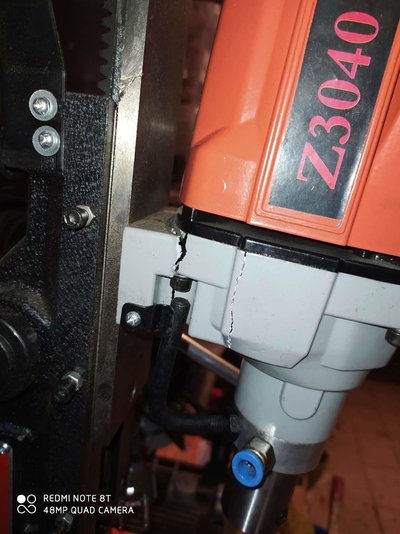

A guy posted the pictures of a Chinese Z4030 magnetic base drill thing

He was pretty frustrated because the gear housing has been cracked while using a big anular cutter

I've contacted him via messenger telling him some tips about repair it so he tried but had not success

He offered it to me for free just shipping costs 18 euros

That's the situation the gear housing is divided in two halves and it's going to crack in another spot .

(I'll upload pictures down here)

My idea is to make a steel enclosure to shrink and secures the parts together .

Wire brush the zamac or magma or whatever cheap and brittle zinc alluminium alloy has been used to make the housing .

Use the center punch on the inside of the steel enclosure and after having press fitted the parts use some chemical anchor to keep all together

Now I would like to know how you'd proceed in my same situation?

Because the in my opinion a simple hose clamp would be enough

I've made a sketch with the measurement of the enclosure for 3x60mm flat stock

My brother in-law gave me an off cut from a 5mm sheet so the measurement would be 4mm bigger

Thanks in advance

(Engine driven welder I was putting the things together when I found my genset or the engine driven air compressor which I could get one soon but it's not sure yet )

Back to the topic the story repeated I was making a magnetic stand when I was reading a Facebook group about welding hobby

A guy posted the pictures of a Chinese Z4030 magnetic base drill thing

He was pretty frustrated because the gear housing has been cracked while using a big anular cutter

I've contacted him via messenger telling him some tips about repair it so he tried but had not success

He offered it to me for free just shipping costs 18 euros

That's the situation the gear housing is divided in two halves and it's going to crack in another spot .

(I'll upload pictures down here)

My idea is to make a steel enclosure to shrink and secures the parts together .

Wire brush the zamac or magma or whatever cheap and brittle zinc alluminium alloy has been used to make the housing .

Use the center punch on the inside of the steel enclosure and after having press fitted the parts use some chemical anchor to keep all together

Now I would like to know how you'd proceed in my same situation?

Because the in my opinion a simple hose clamp would be enough

I've made a sketch with the measurement of the enclosure for 3x60mm flat stock

My brother in-law gave me an off cut from a 5mm sheet so the measurement would be 4mm bigger

Thanks in advance