Submariner1

Member

- Messages

- 194

- Location

- Berkshire

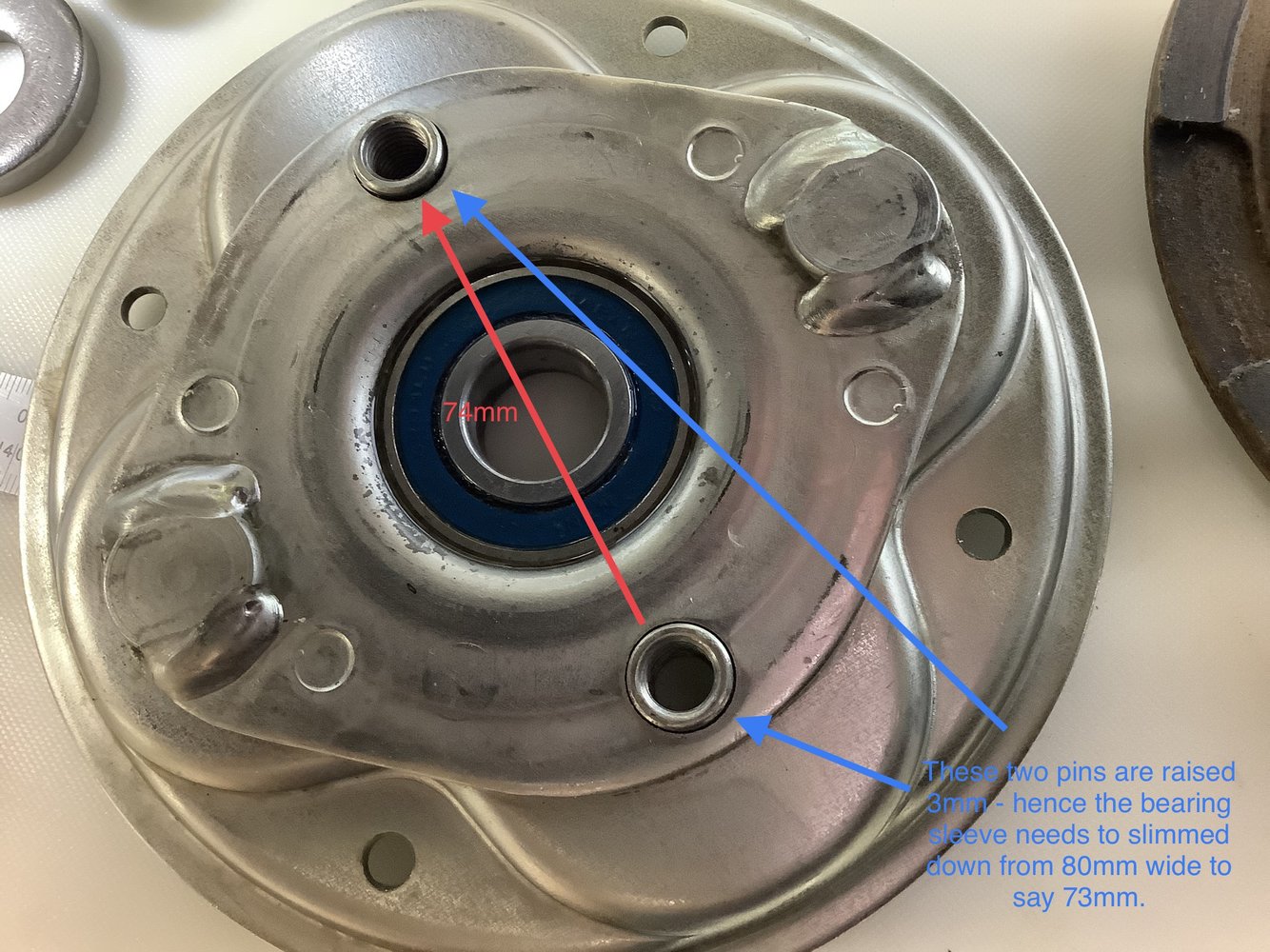

I want to reduce the current O.D. Of a bright steel shaft collar from 80mm to 73mm i.e. 7 mm less diameter

It really only needs to be slimmed down 6mm out of the total 20mm thickness. To miss these 2 pins that are raised about 3mm high.

(Making a sleeve to remove bearings).

Q1 Is it easy for a machinist to skim that 3.5mm deep x 6mm up the collar off? i.e. they would have to hold it in the lathe jaws over just less than 14mm, is that enough?

Q2. Would the grub screw hole, be a problem i.e. damage the cutter, sort of snag it?

(as you can guess I have never used a lathe).

Q3. Any idea what ££ one would have to pay to have this done?

Q4. I have an M12 course pitch, A2 Stainless Steel 100mm Bolt and an M12 A2 Long Nut 36mm x M12 - would that be strong enough to pull out and pull in these 47mm OD x 14mm thick bearings? Are you supposed to oil the steel bearing housing before pulling in a bearing to stop it rusting in?

(Note its on a Lawnmower that gets jet washed around the blade say every 2 weeks).

Obviously if its expensive to machine, I could just grind off an indentation with an angle grinder. Prefer not to go that way, incase it rotates and I blindly crush the raised pin.

Photo Standard bearing Shaft Collar I.D. 50mm O.D. 80mm thickness 20mm . - with grub screw.

It really only needs to be slimmed down 6mm out of the total 20mm thickness. To miss these 2 pins that are raised about 3mm high.

(Making a sleeve to remove bearings).

Q1 Is it easy for a machinist to skim that 3.5mm deep x 6mm up the collar off? i.e. they would have to hold it in the lathe jaws over just less than 14mm, is that enough?

Q2. Would the grub screw hole, be a problem i.e. damage the cutter, sort of snag it?

(as you can guess I have never used a lathe).

Q3. Any idea what ££ one would have to pay to have this done?

Q4. I have an M12 course pitch, A2 Stainless Steel 100mm Bolt and an M12 A2 Long Nut 36mm x M12 - would that be strong enough to pull out and pull in these 47mm OD x 14mm thick bearings? Are you supposed to oil the steel bearing housing before pulling in a bearing to stop it rusting in?

(Note its on a Lawnmower that gets jet washed around the blade say every 2 weeks).

Obviously if its expensive to machine, I could just grind off an indentation with an angle grinder. Prefer not to go that way, incase it rotates and I blindly crush the raised pin.

Photo Standard bearing Shaft Collar I.D. 50mm O.D. 80mm thickness 20mm . - with grub screw.

Am I right in thinking that you simply wish to change the 47mm OD bearings and in doing so intend to buy, and then modify, by machining on a lathe, a standard bearing shaft collar (I.D. 50mm, O.D. 80mm, thickness 20mm, which has a grub screw), to simply assist in removing the bearings?

Am I right in thinking that you simply wish to change the 47mm OD bearings and in doing so intend to buy, and then modify, by machining on a lathe, a standard bearing shaft collar (I.D. 50mm, O.D. 80mm, thickness 20mm, which has a grub screw), to simply assist in removing the bearings?