Screwdriver

Member

- Messages

- 10,939

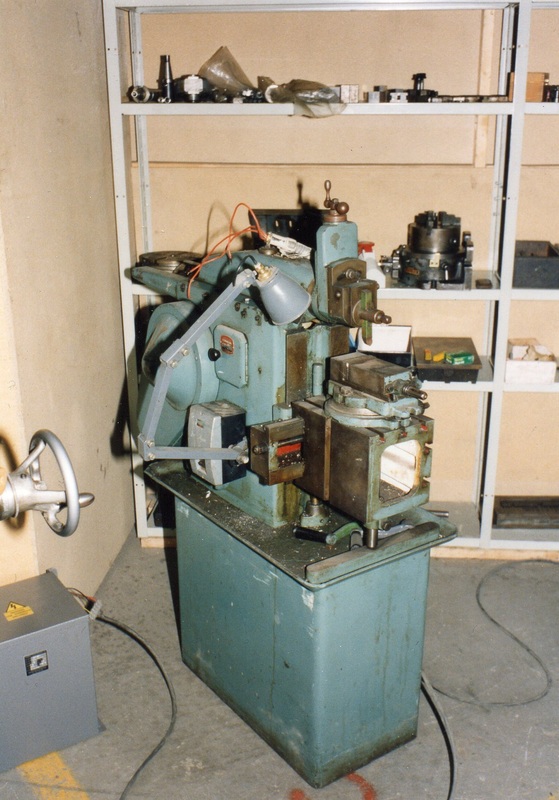

Ideally I'd like a full size Bridgeport milling machine but that will have to wait for various reasons. Meantime I bought myself this:

It's a small, benchtop powered shaper as opposed to a manual device (life's too short). It was cheap enough at £60 and I didn't expect too much from it. I jury rigged a makeshift tensioner so I could stick a belt on it and knocked up a stand in speedframe so I could fit a motor.

Did it in sketchup first of course then made it real.

Goes ok.

But there's a problem with the surface finish. You can hear it actually but here's what it looks like.

And that finish is perpendicular to the tool, the tool is going right to left in that image! The regularity of the surface flaw suggests the problem is with gear noise or rumble from the large drive gear.

I have finessed a fair few bits and pieces already but my next job is to dress the gear wheel on the lathe and make up a new phosphor bronze bushing. I think there's too much play and too much runout on that main gear.

I need either a plain bar or a cored section of phosphor bronze to make a 2" diameter (1.75"ID) by 2.5" long bushing. Can anyone help? Is there some other material I could use?

Cheers

Screwd.

It's a small, benchtop powered shaper as opposed to a manual device (life's too short). It was cheap enough at £60 and I didn't expect too much from it. I jury rigged a makeshift tensioner so I could stick a belt on it and knocked up a stand in speedframe so I could fit a motor.

Did it in sketchup first of course then made it real.

Goes ok.

But there's a problem with the surface finish. You can hear it actually but here's what it looks like.

And that finish is perpendicular to the tool, the tool is going right to left in that image! The regularity of the surface flaw suggests the problem is with gear noise or rumble from the large drive gear.

I have finessed a fair few bits and pieces already but my next job is to dress the gear wheel on the lathe and make up a new phosphor bronze bushing. I think there's too much play and too much runout on that main gear.

I need either a plain bar or a cored section of phosphor bronze to make a 2" diameter (1.75"ID) by 2.5" long bushing. Can anyone help? Is there some other material I could use?

Cheers

Screwd.