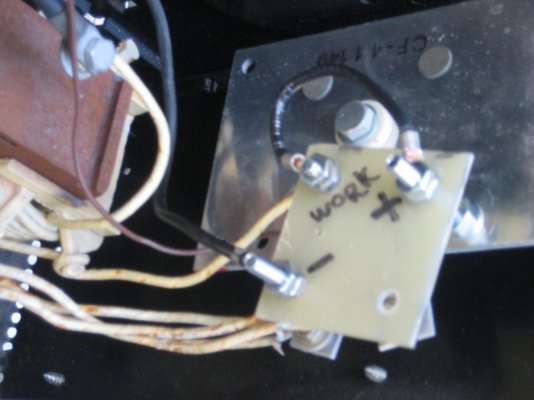

I was recently given a Cebora 833 Mig welder. It came with a regulator, but no gas tank. It came with a reel of flux core wire, too. Since this welder was intended for gas shielded use only and its low cost, there is no provision to reverse the polarity to DCEN for flux core, no gas welding. I took this as a challenge. I traced out the circuit and I discovered the trigger switch connects to the electrode lead in the gun, rather than using a pair of wires to the switch independent of the electrode lead. This seems to be a cost saving measure which complicates the polarity reversal modification. The motor speed control circuit needs raw DC in order to function since it has an SCR to switch. I bit the bullet and added a bridge rectifier so that regardless of the work-electrode polarity, the motor controller always sees the same polarity. The bridge rectifier is readily available at low cost; a wide range of specs (400 volts or more and 10 amps or more) is usable. The particular one I used, 12 Amps and 1000 volts, cost me $0.50 new at a local electronics surplus store. A full price bridge may cost $3 to $5. I fixed the +, -, and work lead terminals to a piece of insulating glass fiber-epoxy sheet. This is printed circuit board base material without copper. The fourth terminal, the electrode lead, I left flying, connected directly to the opposite polarity post from the work lead. The three terminals on this board support the flying leads from the transformer and choke where they are subject to bending otherwise when changing polarity. Notice the inboard side of the choke is strapped for polarity; the work lead proper remains connected to the other end of the choke. The motor controller then always sees the raw DC from the power supply, rather than the arc voltage. You need to add a few wires and move some connections in order to make these changes. I've attached a jpg of the original and changed schematics. When I sketched the changes, they were proposed, but, now I have actually installed them and I can reverse the electrode polarity without any problems with the wirefeed motor control.

Considering the economy of construction of this welder, this change may be overkill, however, it's offered as an idea for others to use as they see fit.

I don't have a photo of the modification to attach at this time.

Jeff Furman

Considering the economy of construction of this welder, this change may be overkill, however, it's offered as an idea for others to use as they see fit.

I don't have a photo of the modification to attach at this time.

Jeff Furman

Last edited by a moderator:

welcome to the forum by the way.

welcome to the forum by the way.