Parm

Respect The Sound System

- Messages

- 17,862

- Location

- Towcester

ive put it in this section as my kitchen is also a Worksop that creates ........... Edible things

My Favorite cast iron pan has suffered with broken handles, no matter what you buy they don't ladt long. A while back I saw a set of similar pans with aluminium handles, so I had a go my self.

It was my first solo lathe project, after a bit of phone consultancy with dad I ground some HSS with a bullnose front. To complement the only other cutter I have.

I turned down the shank with the bull nose then adjusted the to slide at an angle to give me the chamfer I wanted. This wasn't to a dawing, just what looked right by eye.

I then centre drilled, drilled and tapped M6 for a SS pan head bolt.

Faced it off the made a little dished recess to accommodate the curve of the lid

Didn't have a parting off tool, so I cut (with hack saw) the half formed section from the bar so I could hold it the other way round.

Used some very thin copper sheet wrapped round the mandrel section of the handle to hold in the chuck

Faced off, rounded edges with a file and made a slight dish in the visible part of the handle.

Cleaned off with some wet n dry then quick rub with a garryson block followed by a quick buff with a cloth mop mounted in my wood lathe

Not a complicated project by some of the work ive seen in here, but complicated enough for me as a starter

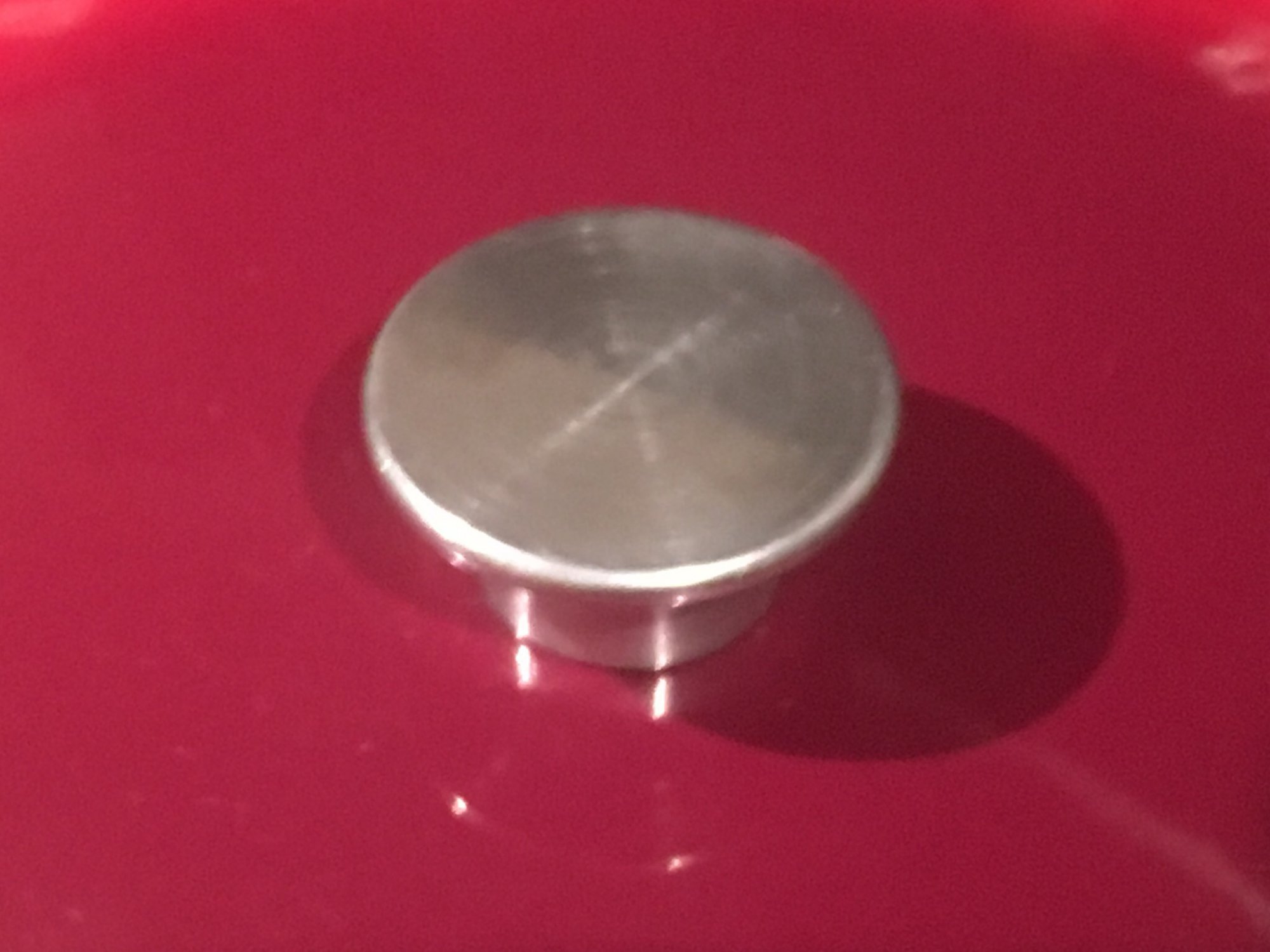

Here is the result

And yes, before you all say, yes it's going to get hot, but so did the crappy plastic ones, so I'm in the habit of always using some hot pads

My Favorite cast iron pan has suffered with broken handles, no matter what you buy they don't ladt long. A while back I saw a set of similar pans with aluminium handles, so I had a go my self.

It was my first solo lathe project, after a bit of phone consultancy with dad I ground some HSS with a bullnose front. To complement the only other cutter I have.

I turned down the shank with the bull nose then adjusted the to slide at an angle to give me the chamfer I wanted. This wasn't to a dawing, just what looked right by eye.

I then centre drilled, drilled and tapped M6 for a SS pan head bolt.

Faced it off the made a little dished recess to accommodate the curve of the lid

Didn't have a parting off tool, so I cut (with hack saw) the half formed section from the bar so I could hold it the other way round.

Used some very thin copper sheet wrapped round the mandrel section of the handle to hold in the chuck

Faced off, rounded edges with a file and made a slight dish in the visible part of the handle.

Cleaned off with some wet n dry then quick rub with a garryson block followed by a quick buff with a cloth mop mounted in my wood lathe

Not a complicated project by some of the work ive seen in here, but complicated enough for me as a starter

Here is the result

And yes, before you all say, yes it's going to get hot, but so did the crappy plastic ones, so I'm in the habit of always using some hot pads