I've posted about mine in different threads since I've got it, so now I've just done some more mods to my air system I thought I'd cover it all in a single thread.

so this is the compressor I bought

http://www.ukhs.tv/Dakota-14-CFM-Air-Compressor

and my first issue with it was that I was unable to fit it under my workbench, so it got lowered 40mm,the back was easy to do, just by drillling a couple of holes

but the front required a small frame to be welded up to take 2 wheels at the side instead of one in the middle

people are also fitting drain valves for the reciever that are operated on electrical timers, but I already had an old clarke air filter with automatic drain valve

https://www.machinemart.co.uk/p/clarke-cat152-14-mini-air-filter/

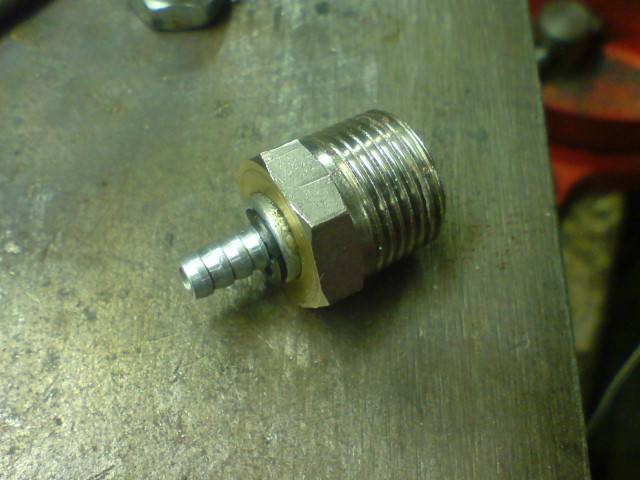

so the drain valve got removed and that was loctited into bush that was then screwed into the original drain plug position

Ive also recently changed the regulator on it as it was far too restrictive.the replacement filter is a clarke one, which is far less restrictive, but there is a small air leak between the diaphragm and lower and upper halves of the regulator body, I can live with that as its more hassle to take it back

https://www.machinemart.co.uk/p/clarke-cat865-air-regulator-with-gauge/

here it is shown with the desiccant dryer I made earlier and now fitted with a new filter and filter regulator due to the original ones being too restrictive.

and the dryer on its own

the desiccant air dryer, uses silica gel desiccant, which absorbs moisture from the air, and changes colour as it gets wet so you know when to dry it out. (you can see this in the above picture as the beads have changed to blue at the top (wet) from brown at the bottom (dry)

http://www.ebay.co.uk/itm/380853696993

and a 10" water housing filter, the one in the link below has a working pressure of 150psi, but others have working pressures of as little as 60psi, which may be an issue

http://www.ebay.co.uk/itm/112080808285

a copper tube is stick into the lid using car body filler, and the other end has some slots cut in it and a cap put on the end. the cap has been domed as is makes it easier to screw the filter housing lid back on

I ended up with the set up of compressor > regulator > filter > dryer > filter/regulator.

another alternative was compressor > dryer > filter/regulator

I could have ditched the first regulator as the filter housing has a working pressure of 150psi, which is the pressure at which the compressor turns off I have the pressure set at 100psi as the compressor turns on again when the pressure drops to 105psi. The filter is there to remove any water droplets (and possibly oil) before the air gets to the desiccant crystals. the filter/regulator is to remove any debris from the desiccant crystals and the regulate the pressure into the air line.

I ended up getting a shako filter and filter/regulator, as they were cheapish, you can get the full specifications of them and they have automatic drain valves on them.

http://www.shako-online-sales.com/frl/filter-regulators/filter-regulator-NUFR02-NUFR03-NUFR04

http://www.shako-online-sales.com/frl/filter-NUF-02-NUF-03-NUF-04

if you buy from the manufacturer you can specify the options you want, but I got them from here

http://www.solenoid-valve.world/

but the filter/regulator comes with a 25mm diameter gauge which is pretty useless( they dont supply them with standard 40 or 50mm gauges).

I was pretty impressed with the build quality of these and they seem to be better than the quivalent clarke products. the bowl and cover for the filters just twist into place and the bowl is sealed with an o ring on the outside. looks like they will be easy to remove if I need to take them off again in years to come

I ended up making a new pressure gauge adaptor for the filter regulator from an offcut of aluminim. you can also fit a pressure guage to the filter on its own if you want. I also mounted the gauge horizontally so I don't have to bend down to read it when I adjusting the regulator.

inside my garage I just use normal air hoses, but for my connection on the outside of my garage I have used 10mm pvc hose and 15mm copper pipe. to join those I used

10mm 1/4bsp hose tail > 1/4bsp socket > 8mm to 15mm plumbing compression reducer

and the outside I used

15mm compression elbow > 15mm to 8mm reducer > pcl coupling

the reason why I've recently upgraded parts of my set up was that one of my spray guys wasn't getting enough air. even though its a Low Volume Low Pressure (LVLP) with a regulator on the spray gun the maximum pressure I could get at spraygun was 10psi with all the original mini regulators wound down to give full pressure.

I've ditched all the regulators on the spray guns and now just use a T piece with the gauge and pcl adaptor on it (also now xf fittings to flow more air). Ive now got plenty of air for my requirements, and its easy enough to alter the pressure on the filter/regulator by the desiccant dryer.

think that me sorted for the time being until I decide to change something again, and some bits of this might be of use to someone else

so this is the compressor I bought

http://www.ukhs.tv/Dakota-14-CFM-Air-Compressor

and my first issue with it was that I was unable to fit it under my workbench, so it got lowered 40mm,the back was easy to do, just by drillling a couple of holes

but the front required a small frame to be welded up to take 2 wheels at the side instead of one in the middle

people are also fitting drain valves for the reciever that are operated on electrical timers, but I already had an old clarke air filter with automatic drain valve

https://www.machinemart.co.uk/p/clarke-cat152-14-mini-air-filter/

so the drain valve got removed and that was loctited into bush that was then screwed into the original drain plug position

Ive also recently changed the regulator on it as it was far too restrictive.the replacement filter is a clarke one, which is far less restrictive, but there is a small air leak between the diaphragm and lower and upper halves of the regulator body, I can live with that as its more hassle to take it back

https://www.machinemart.co.uk/p/clarke-cat865-air-regulator-with-gauge/

here it is shown with the desiccant dryer I made earlier and now fitted with a new filter and filter regulator due to the original ones being too restrictive.

and the dryer on its own

the desiccant air dryer, uses silica gel desiccant, which absorbs moisture from the air, and changes colour as it gets wet so you know when to dry it out. (you can see this in the above picture as the beads have changed to blue at the top (wet) from brown at the bottom (dry)

http://www.ebay.co.uk/itm/380853696993

and a 10" water housing filter, the one in the link below has a working pressure of 150psi, but others have working pressures of as little as 60psi, which may be an issue

http://www.ebay.co.uk/itm/112080808285

a copper tube is stick into the lid using car body filler, and the other end has some slots cut in it and a cap put on the end. the cap has been domed as is makes it easier to screw the filter housing lid back on

I ended up with the set up of compressor > regulator > filter > dryer > filter/regulator.

another alternative was compressor > dryer > filter/regulator

I could have ditched the first regulator as the filter housing has a working pressure of 150psi, which is the pressure at which the compressor turns off I have the pressure set at 100psi as the compressor turns on again when the pressure drops to 105psi. The filter is there to remove any water droplets (and possibly oil) before the air gets to the desiccant crystals. the filter/regulator is to remove any debris from the desiccant crystals and the regulate the pressure into the air line.

I ended up getting a shako filter and filter/regulator, as they were cheapish, you can get the full specifications of them and they have automatic drain valves on them.

http://www.shako-online-sales.com/frl/filter-regulators/filter-regulator-NUFR02-NUFR03-NUFR04

http://www.shako-online-sales.com/frl/filter-NUF-02-NUF-03-NUF-04

if you buy from the manufacturer you can specify the options you want, but I got them from here

http://www.solenoid-valve.world/

but the filter/regulator comes with a 25mm diameter gauge which is pretty useless( they dont supply them with standard 40 or 50mm gauges).

I was pretty impressed with the build quality of these and they seem to be better than the quivalent clarke products. the bowl and cover for the filters just twist into place and the bowl is sealed with an o ring on the outside. looks like they will be easy to remove if I need to take them off again in years to come

I ended up making a new pressure gauge adaptor for the filter regulator from an offcut of aluminim. you can also fit a pressure guage to the filter on its own if you want. I also mounted the gauge horizontally so I don't have to bend down to read it when I adjusting the regulator.

inside my garage I just use normal air hoses, but for my connection on the outside of my garage I have used 10mm pvc hose and 15mm copper pipe. to join those I used

10mm 1/4bsp hose tail > 1/4bsp socket > 8mm to 15mm plumbing compression reducer

and the outside I used

15mm compression elbow > 15mm to 8mm reducer > pcl coupling

the reason why I've recently upgraded parts of my set up was that one of my spray guys wasn't getting enough air. even though its a Low Volume Low Pressure (LVLP) with a regulator on the spray gun the maximum pressure I could get at spraygun was 10psi with all the original mini regulators wound down to give full pressure.

I've ditched all the regulators on the spray guns and now just use a T piece with the gauge and pcl adaptor on it (also now xf fittings to flow more air). Ive now got plenty of air for my requirements, and its easy enough to alter the pressure on the filter/regulator by the desiccant dryer.

think that me sorted for the time being until I decide to change something again, and some bits of this might be of use to someone else

haven't done any of mine in a year I must remember to have a look

haven't done any of mine in a year I must remember to have a look  it will fill faster if there's water in

it will fill faster if there's water in