Bit of a story!

I am having fun with plasma cutting, and notice as one would expect, the higher the air pressure then the cleaner the cut. One manual suggests I should be needing 90 Litres air per minute at 4.8 bar, the nozzle has a 1mm hole.

An on line calculator suggests that at those settings I should only need around 56 litres air per min, but I can run out of air no problems.

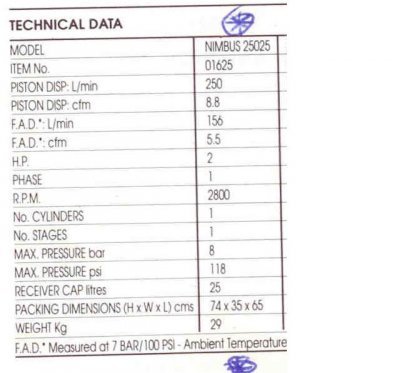

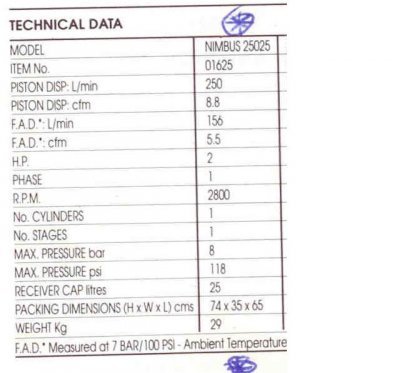

So I have this old SIP nimbus 25025 compressor and it was getting hot, not unexpected really, poor thing was just not coping was never intended for continuous running (only meant for 2.5 mins at a time).

So I got a petrol compressor with a 100 litre tank, and I can run out with that!!!

So something must be wrong and I am wondering if it is my set-up.

I am running via two regulators, one is quite small same size as on the back of the plasma and this is set to 6 bar, this then goes to the one on the plasma cutter and this is set to 5 bar.

So my questions is am I making my compressors work even harder by doing this, should I go and by a bigger regulator and do it in one stage.

I did it because I thought it would be better to do it this way but wondering if by forcing the system to have a higher pressures in the compressor tank I am making it less efficient and wasteful?

Both the Sip and the newer petrol compressor have a 250 litre displacement cylinder

Advice gratefully received even if how to link both units together?

Adrian

I am having fun with plasma cutting, and notice as one would expect, the higher the air pressure then the cleaner the cut. One manual suggests I should be needing 90 Litres air per minute at 4.8 bar, the nozzle has a 1mm hole.

An on line calculator suggests that at those settings I should only need around 56 litres air per min, but I can run out of air no problems.

So I have this old SIP nimbus 25025 compressor and it was getting hot, not unexpected really, poor thing was just not coping was never intended for continuous running (only meant for 2.5 mins at a time).

So I got a petrol compressor with a 100 litre tank, and I can run out with that!!!

So something must be wrong and I am wondering if it is my set-up.

I am running via two regulators, one is quite small same size as on the back of the plasma and this is set to 6 bar, this then goes to the one on the plasma cutter and this is set to 5 bar.

So my questions is am I making my compressors work even harder by doing this, should I go and by a bigger regulator and do it in one stage.

I did it because I thought it would be better to do it this way but wondering if by forcing the system to have a higher pressures in the compressor tank I am making it less efficient and wasteful?

Both the Sip and the newer petrol compressor have a 250 litre displacement cylinder

Advice gratefully received even if how to link both units together?

Adrian