Pollys13

Member

- Messages

- 376

- Location

- Wiltshire UK

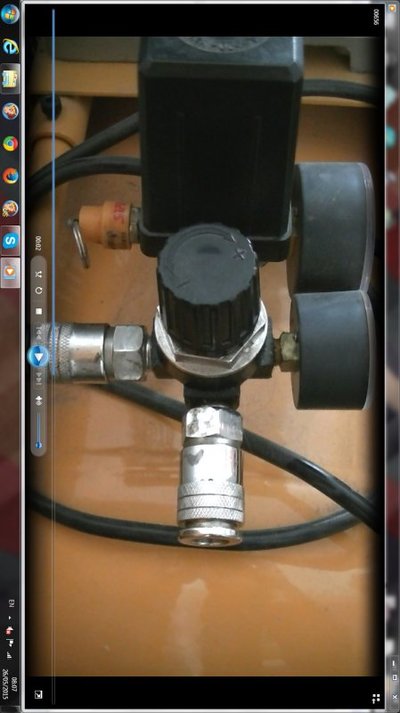

My compressor displaces 397 litres/minute (14CFM) The maximum pressure I

will be using is 50 psi, the air is introduced to the system at 90 psi and passes through a couple of regulators, one drops the pressure to 65 psi the other to 40 psi.

These regulators are shown in the attached photo.

I've bought the correct connectors for the part of system I've worked out how to connect so far.

Most of these are 1/4" BSP, connected into 3/8" ball valves and a 1/2" NPT adapter.

Details of the connectors I'm using are a bit later in this post.

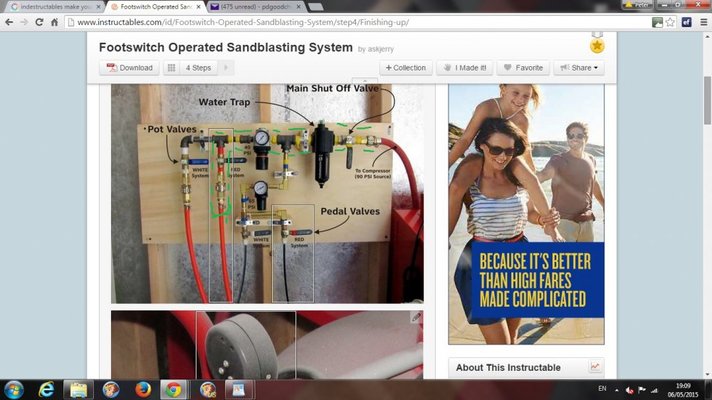

The connectors I've bought or ordered are shown by the green dashed line in the photo

This I'm using as a template for the arrangement of the component parts for my air supply system.

I'm wondering though if how I've connected up will allow for the optimum

correct air flow?

The air line had an ID of 13mm one end of this is connected to the compressor using a 1/2" x 1/4" union the other end introducing the air supply also has a 1/2" x 1/4" union.

This then fits via a 1/4" x 3/8" reducing union into a 3/8" ball valve.

The ball valve is then connected via an NPT adapter 3/8" BSP x 1/2" NPT

to the 1/2" NPT water trap.

The other side of the water trap is connected to a 3 way 1/4" BSP tee

via another NPT adapter this time 1/2" NPT x 1/4" BSP

This tee is connected by a 1/4" hex barrel to the first Chinese regulater which has a port size of

1/4" BSP.

The other side of this regulator has a 1/4" BSP 180mm extended nipple fitted to it

This runs into a 1/4" BSP elbow

To fit into this I've bought a 1/4" x 3/8" adapter

this fits into another 3/8" ball valve.

Going into the ball valve I then have a hose tail male 3/8" bsp x 1/4" hose ID

I connect the air line that came with the pot to this.

Am I going to be getting the correct, optimum air flow using the 1/4" regulators

and 1/4" pipe and connectors, or do they restrict the air flow too much?

Should I replace the regulators with 1/2" ones and 1/2" pipe and connectors?

Cheers.

will be using is 50 psi, the air is introduced to the system at 90 psi and passes through a couple of regulators, one drops the pressure to 65 psi the other to 40 psi.

These regulators are shown in the attached photo.

I've bought the correct connectors for the part of system I've worked out how to connect so far.

Most of these are 1/4" BSP, connected into 3/8" ball valves and a 1/2" NPT adapter.

Details of the connectors I'm using are a bit later in this post.

The connectors I've bought or ordered are shown by the green dashed line in the photo

This I'm using as a template for the arrangement of the component parts for my air supply system.

I'm wondering though if how I've connected up will allow for the optimum

correct air flow?

The air line had an ID of 13mm one end of this is connected to the compressor using a 1/2" x 1/4" union the other end introducing the air supply also has a 1/2" x 1/4" union.

This then fits via a 1/4" x 3/8" reducing union into a 3/8" ball valve.

The ball valve is then connected via an NPT adapter 3/8" BSP x 1/2" NPT

to the 1/2" NPT water trap.

The other side of the water trap is connected to a 3 way 1/4" BSP tee

via another NPT adapter this time 1/2" NPT x 1/4" BSP

This tee is connected by a 1/4" hex barrel to the first Chinese regulater which has a port size of

1/4" BSP.

The other side of this regulator has a 1/4" BSP 180mm extended nipple fitted to it

This runs into a 1/4" BSP elbow

To fit into this I've bought a 1/4" x 3/8" adapter

this fits into another 3/8" ball valve.

Going into the ball valve I then have a hose tail male 3/8" bsp x 1/4" hose ID

I connect the air line that came with the pot to this.

Am I going to be getting the correct, optimum air flow using the 1/4" regulators

and 1/4" pipe and connectors, or do they restrict the air flow too much?

Should I replace the regulators with 1/2" ones and 1/2" pipe and connectors?

Cheers.