MattH

Member

- Messages

- 4,535

- Location

- Cornwall

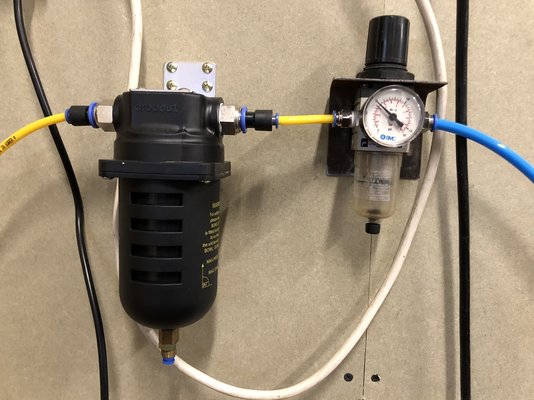

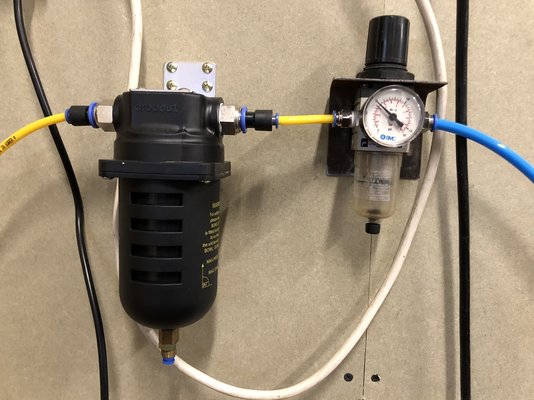

I recently bought a PCL Dropout to remove any water from an airline that feeds one of my Laser cutters:

https://www.pclairtechnology.com/pr...ing_wp_cron=1539248371.4563210010528564453125

Seems like a good unit and a cheaper and easier solution over a desiccant filter.

It has a standard autodrain on the bottom i.e. a small spring loaded valve that shuts with air pressure.

My question is, my compressor and air line that run the laser cutter is tight with no leaks. I turn it off after cutting and when I turn it back on the next day there is still plenty of pressure.

This means that the autodrain will never function and the Dropout will fill up with water.

How do I get this thing to drain?

The reg next to the unit has a manual drain which I was opening each morning, but there's no way to open the Dropouts drain with out venting the system.

(the brass pushfit fitting on the autodrain is something I added on so I can run a poly line to a container to catch any discharge).

https://www.pclairtechnology.com/pr...ing_wp_cron=1539248371.4563210010528564453125

Seems like a good unit and a cheaper and easier solution over a desiccant filter.

It has a standard autodrain on the bottom i.e. a small spring loaded valve that shuts with air pressure.

My question is, my compressor and air line that run the laser cutter is tight with no leaks. I turn it off after cutting and when I turn it back on the next day there is still plenty of pressure.

This means that the autodrain will never function and the Dropout will fill up with water.

How do I get this thing to drain?

The reg next to the unit has a manual drain which I was opening each morning, but there's no way to open the Dropouts drain with out venting the system.

(the brass pushfit fitting on the autodrain is something I added on so I can run a poly line to a container to catch any discharge).