gasket999

getting there...

- Messages

- 355

- Location

- Manchester, UK

Only a quick one folks, just hoping for some advice.

The fixed airlines in my workshop are all 15mm copper pipe with a few manifolds - the manifolds have PCL AC71 XF female couplings. To get the air from the compressor into the airlines as effectively as possible, I have a big PCL 100-series whip hose ending in a male PCL100 connector - these are the giant ones that give the bigger airflow.

I plan to screw a male threaded but female PCL100 receiver connector straight into the end of the compressor tank - this is only a smaller, mobile compressor so it would be nice to be able to disconnect it from the system where needed.

The compressor arrived today, its one of the new NuAir 3hp ones that are apparently quite quiet (ignore the "HP2" sticker on the tank, its an error). The tank bung was not fitted and it came with a generic female euro connector to screw into the tank. All I'll be doing is replacing this normal euro connector with a big PCL100 alternative.

But here's the query:

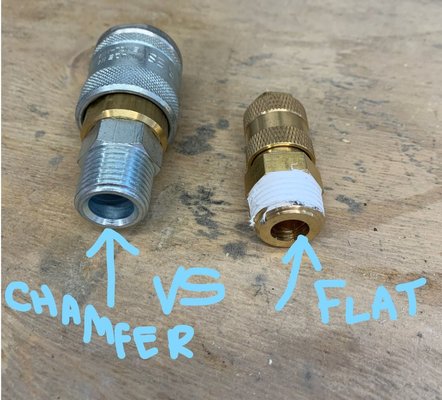

The connector that came with the compressor has a flat end to the threaded stem. As if it is going to seal against a flat surface. The PCL100 connector I have ends in a chamfer, as if an olive is going to go into it. Am I OK to screw this PCL100 directly into the threaded boss on the end of the tank or will it leak or damage the thread (I do get confused with pipe threads and tapers).

The fixed airlines in my workshop are all 15mm copper pipe with a few manifolds - the manifolds have PCL AC71 XF female couplings. To get the air from the compressor into the airlines as effectively as possible, I have a big PCL 100-series whip hose ending in a male PCL100 connector - these are the giant ones that give the bigger airflow.

I plan to screw a male threaded but female PCL100 receiver connector straight into the end of the compressor tank - this is only a smaller, mobile compressor so it would be nice to be able to disconnect it from the system where needed.

The compressor arrived today, its one of the new NuAir 3hp ones that are apparently quite quiet (ignore the "HP2" sticker on the tank, its an error). The tank bung was not fitted and it came with a generic female euro connector to screw into the tank. All I'll be doing is replacing this normal euro connector with a big PCL100 alternative.

But here's the query:

The connector that came with the compressor has a flat end to the threaded stem. As if it is going to seal against a flat surface. The PCL100 connector I have ends in a chamfer, as if an olive is going to go into it. Am I OK to screw this PCL100 directly into the threaded boss on the end of the tank or will it leak or damage the thread (I do get confused with pipe threads and tapers).

two chamfers, that's sneaky, lol

two chamfers, that's sneaky, lol