wyn

Member

- Messages

- 3,728

- Location

- Cardiff

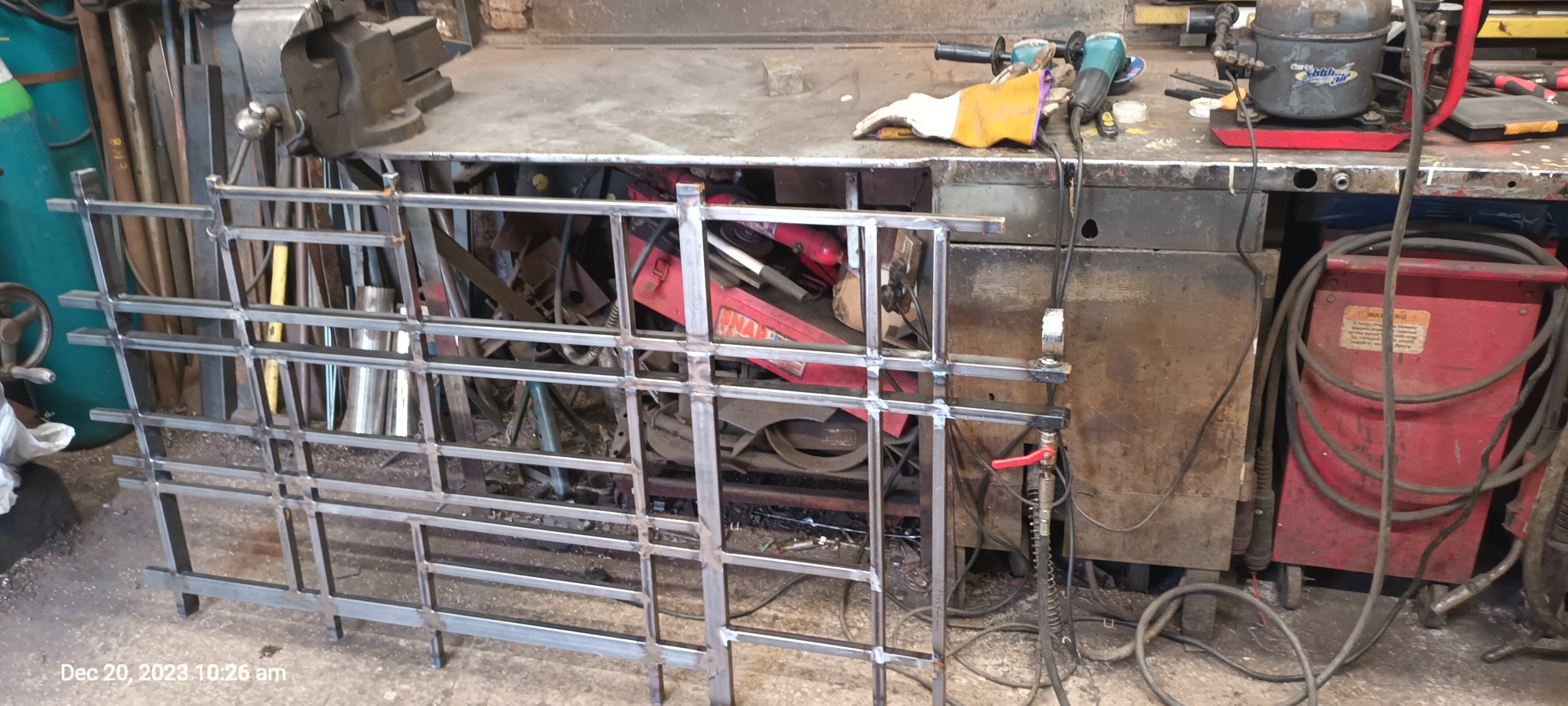

Following on from my "mondrian" style shelving i'm now having a bash at a radiator in a similar style.

It's made up from 20x20 box and 40x20 rectangular.

Starting off. It's about 6' x 3'

The two main uprights are 40x20 with the 20 facing outwards and 40mm deep.

The water is supposed to run up the tubes on the left and down the ones on the right of the longest verticals.

The two sides are only connected by the top horizontal tube. The little cross pieces joining the main uprights don't carry water.

The vertical bits above the top horizontal don't carry water......just for show.

Made some female 1/2" bsp fittings and welded into the sides of the main uprights

Filled it with water and then pressurised with air up to 45 psi to check for leaks.

There were quite a few pinholes that needed going over. It has all been tig welded to try to eliminate leaks.

It held the same pressure for a couple of hours so should be good to carry on. If there were too many problems i was still prepared to cut it up and chuck it, if it turned out to be a nightmare.

All the welding caused it to bow quite a bit.

Clamped it down and warmed it up with a cutting torch to get it to relax a bit.

That's about it at the mo.

The frame will be black and have some sheet welded to the back of the rectangles, these will then be painted various colours. Some rectangles will be left blank so the colour of the wall can be seen behind.

There is a vent plug in the top horizontal tube for bleeding and it needs some brackets to hold it to the wall.

Having a bit of a dabble on "paint" to see what it might look like.

It's made up from 20x20 box and 40x20 rectangular.

Starting off. It's about 6' x 3'

The two main uprights are 40x20 with the 20 facing outwards and 40mm deep.

The water is supposed to run up the tubes on the left and down the ones on the right of the longest verticals.

The two sides are only connected by the top horizontal tube. The little cross pieces joining the main uprights don't carry water.

The vertical bits above the top horizontal don't carry water......just for show.

Made some female 1/2" bsp fittings and welded into the sides of the main uprights

Filled it with water and then pressurised with air up to 45 psi to check for leaks.

There were quite a few pinholes that needed going over. It has all been tig welded to try to eliminate leaks.

It held the same pressure for a couple of hours so should be good to carry on. If there were too many problems i was still prepared to cut it up and chuck it, if it turned out to be a nightmare.

All the welding caused it to bow quite a bit.

Clamped it down and warmed it up with a cutting torch to get it to relax a bit.

That's about it at the mo.

The frame will be black and have some sheet welded to the back of the rectangles, these will then be painted various colours. Some rectangles will be left blank so the colour of the wall can be seen behind.

There is a vent plug in the top horizontal tube for bleeding and it needs some brackets to hold it to the wall.

Having a bit of a dabble on "paint" to see what it might look like.