Dr.Al

Forum Supporter

- Messages

- 2,723

- Location

- Gloucestershire, UK

As requested by @bigegg, a review of my very recent acquisition of a Chinese copy of a Bridge City Kerfmaker. I've only had it for a day so far and only used it on practice pieces, but so far I'm impressed and happy with it.

What is it?

Sold as a Kerfmaker by Bridge City (for £38 when I checked), but copied and sold on ebay (for £15) with the catchy name of "Regulator W/ Push Table Saw Slot Movable Measuring Tool Woodworking" or variations of that theme. Search for "regulator table saw" on ebay and you'll get plenty of links.

It's a tool for making it easy to cut housing joints or other grooves that have to be a specific width. It essentially does the subtraction of saw kerf (or router bit size) automatically so you don't have to measure anything.

How is it used?

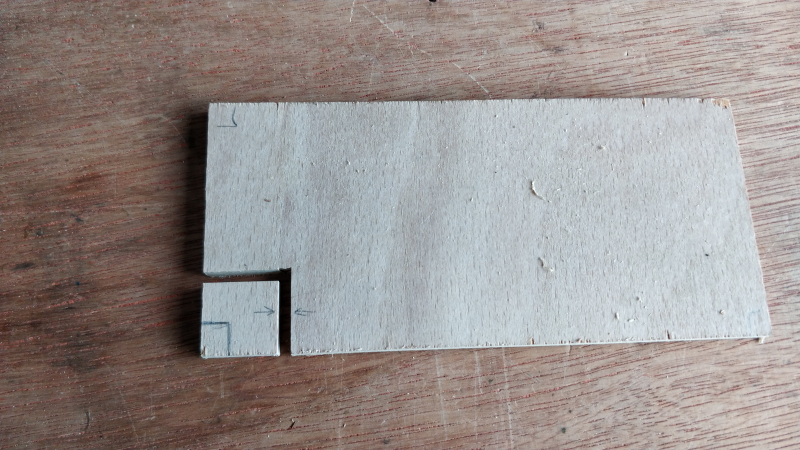

With a table saw or router bit. Start by getting a bit of scrap wood with at least one corner with an accurate right angle. Take two cuts in the corner to remove a rectangle (size doesn't matter), but be careful to make note of which way round the rectangle was:

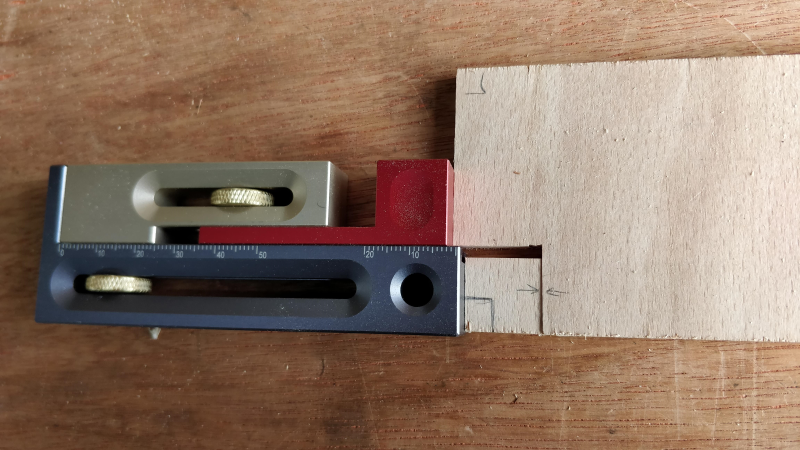

Slide the loose bit up against the main body. Then get the kerfmaker, set the gold-ish coloured main body slider to 0 (flush with the blue bit) and set the red slider using the scrap wood:

Next time I do this, I'll use a thicker bit of scrap wood and glue and/or screw (with a recessed screw) the removed bit of wood onto the main body: I can then keep it as a reference and maybe use all four corners for different blades or router bits.

Now get the piece of wood you want to run in a slot and set the gold-ish coloured slider to the width of the wood.

Then use it as an end stop offset when cutting the two ends of a groove on the table saw (framed shots as I didn't bother to do more cuts):

Do lots of cuts to fill in the gap and clean the bottom of the cut (assuming your table saw blade doesn't have a square tip) with a chisel or whatever.

Et voila, a perfect fit:

How did I find it to use?

It took me a couple of attempts to get it right. I hadn't pushed the gold sliding bit firmly up against the blue body before setting the kerf width and hence it was slightly too tight on my first two attempts. I thought it was down to the variability that comes from wood's flexibility when setting the groove width, but when I realised what I'd done wrong and re-set the kerf, it was spot on first time.

Build quality etc...

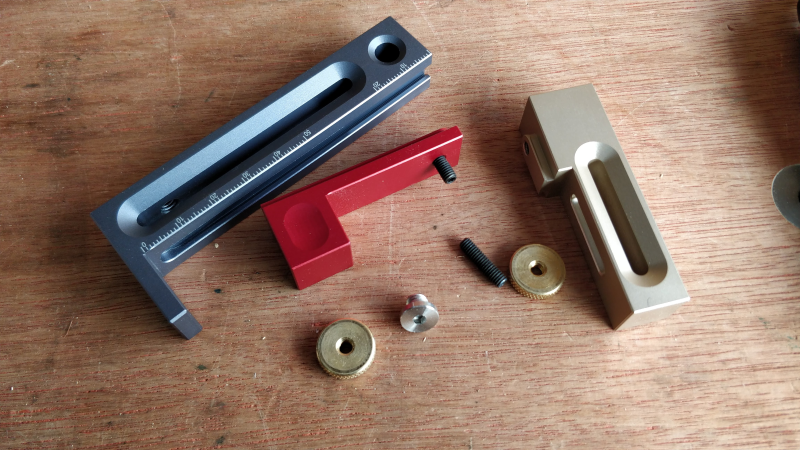

Here are the bits that make up the kerfmaker / regulator. All anodised aluminium with brass knurled clamp nuts.

Fasteners are all metric, which is a very good thing in my opinion (I imagine the Bridge City one uses UNC rubbish). The scale on the side of the body is also metric, although there isn't much point to the scale apart from as a sanity check: the whole point of this thing is that you don't need to measure anything.

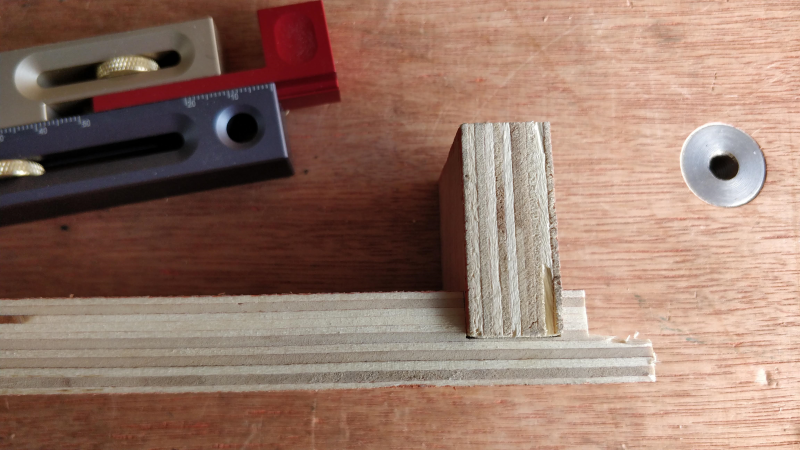

One slight oddity is that the blue body has a dovetail slot, but the parts that slide in the dovetail are almost t-shaped (albeit with a chamfer to match the dovetail angle):

It's hardly a precision instrument in the metalworking sense of the word though, so I don't think it matters. I guess they cut the corners off to remove a potential weak point and undercut the top part (in the orientation of that photo) in case of burrs in the dovetail. The parts slide freely in the dovetail and lock into place without moving around, so that seems fine in my book.

The screw that goes in the bottom (and is purely there to cover one of the grub screws after assembly) was loose when I received it. I tightened it up and the whole mechanism jammed! On inspection, the screw was designed to be flush with the inside slot of the body, but was protruding slightly around the rim. About 4 strokes with a file sorted that out:

Would I buy it again?

Definitely.

Given it's only £15, I'm actually idly wondering about buying a second one. With a straight-edge clamped to a work-piece, two of these could be used to offset a second straight edge (one at each end) and then that second straight edge used as a reference for a router. The only problem with that idea is the groove would have to be far enough away from the edge of the board to allow two straight edges, the kerfmaker and the radius of the router base to fit.

What is it?

Sold as a Kerfmaker by Bridge City (for £38 when I checked), but copied and sold on ebay (for £15) with the catchy name of "Regulator W/ Push Table Saw Slot Movable Measuring Tool Woodworking" or variations of that theme. Search for "regulator table saw" on ebay and you'll get plenty of links.

It's a tool for making it easy to cut housing joints or other grooves that have to be a specific width. It essentially does the subtraction of saw kerf (or router bit size) automatically so you don't have to measure anything.

How is it used?

With a table saw or router bit. Start by getting a bit of scrap wood with at least one corner with an accurate right angle. Take two cuts in the corner to remove a rectangle (size doesn't matter), but be careful to make note of which way round the rectangle was:

Slide the loose bit up against the main body. Then get the kerfmaker, set the gold-ish coloured main body slider to 0 (flush with the blue bit) and set the red slider using the scrap wood:

Next time I do this, I'll use a thicker bit of scrap wood and glue and/or screw (with a recessed screw) the removed bit of wood onto the main body: I can then keep it as a reference and maybe use all four corners for different blades or router bits.

Now get the piece of wood you want to run in a slot and set the gold-ish coloured slider to the width of the wood.

Then use it as an end stop offset when cutting the two ends of a groove on the table saw (framed shots as I didn't bother to do more cuts):

Do lots of cuts to fill in the gap and clean the bottom of the cut (assuming your table saw blade doesn't have a square tip) with a chisel or whatever.

Et voila, a perfect fit:

How did I find it to use?

It took me a couple of attempts to get it right. I hadn't pushed the gold sliding bit firmly up against the blue body before setting the kerf width and hence it was slightly too tight on my first two attempts. I thought it was down to the variability that comes from wood's flexibility when setting the groove width, but when I realised what I'd done wrong and re-set the kerf, it was spot on first time.

Build quality etc...

Here are the bits that make up the kerfmaker / regulator. All anodised aluminium with brass knurled clamp nuts.

Fasteners are all metric, which is a very good thing in my opinion (I imagine the Bridge City one uses UNC rubbish). The scale on the side of the body is also metric, although there isn't much point to the scale apart from as a sanity check: the whole point of this thing is that you don't need to measure anything.

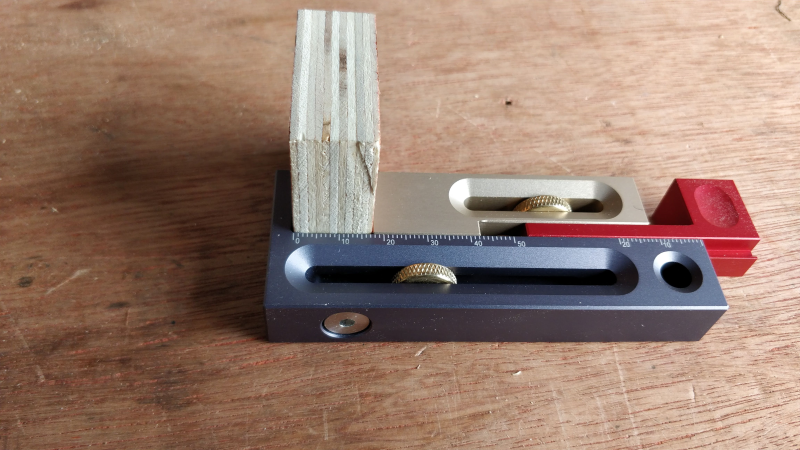

One slight oddity is that the blue body has a dovetail slot, but the parts that slide in the dovetail are almost t-shaped (albeit with a chamfer to match the dovetail angle):

It's hardly a precision instrument in the metalworking sense of the word though, so I don't think it matters. I guess they cut the corners off to remove a potential weak point and undercut the top part (in the orientation of that photo) in case of burrs in the dovetail. The parts slide freely in the dovetail and lock into place without moving around, so that seems fine in my book.

The screw that goes in the bottom (and is purely there to cover one of the grub screws after assembly) was loose when I received it. I tightened it up and the whole mechanism jammed! On inspection, the screw was designed to be flush with the inside slot of the body, but was protruding slightly around the rim. About 4 strokes with a file sorted that out:

Would I buy it again?

Definitely.

Given it's only £15, I'm actually idly wondering about buying a second one. With a straight-edge clamped to a work-piece, two of these could be used to offset a second straight edge (one at each end) and then that second straight edge used as a reference for a router. The only problem with that idea is the groove would have to be far enough away from the edge of the board to allow two straight edges, the kerfmaker and the radius of the router base to fit.