Picked up a Combi 130 Art 888 to replace a Snap-Mig Turbo (Art 886) that got stolen.

I was going to convert the Snap on to dual polarity for gas/ gasless.

When I was looking at upgrading that welder BruceTS mentioned adding a 100000µF capacitor (C1) and 50Ω 25W bleed resistor (R1) to improve the welds produced and adding a second bridge rectifier to isolate the feed motor from the main smoothing capacitor to prevent wire feed run on while the capacitor is charged when the trigger is released and adding a 100µF capacitor (C2) across the feed motor to smooth the feed.

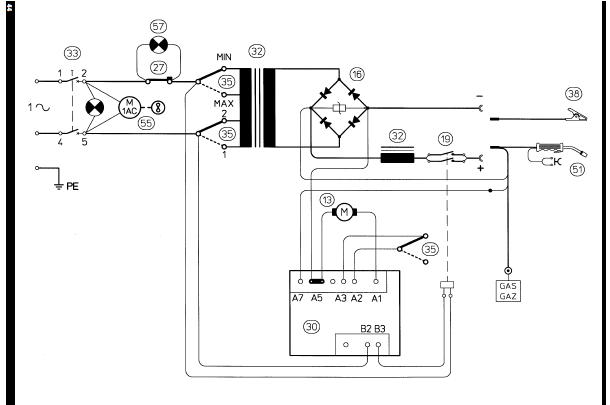

BruceTS's diagram.

The Combi has a two wire trigger and the contactor switches the + torch feed where as the Snap Mig has a single wire trigger switch and the contactor switches the - earth clamp.

Combi 888 Schematic

Will I still need to fit a second bridge rectifier?

What value capacitors would I need?

100000µF (0.1F) was mentioned but I've seen in other threads 47000µF caps mentioned as they don't increase the power output as I will be using the welder for car bodywork, exhausts and light fabrication like making bumper and side pod mounts out of tube for an old kart I'm rebuilding.

My welder doesn't have the thermal cut out warning light, Is it worth fitting one? Is it as simple as it looks, I presume its a 240V AC neon indicator wired in parallel with the thermostat. It would be simple for me to drill the front panel and fit one.

I was planning on fitting a euro torch, I got Trafimet Ergoplus 4m MB15 torch and was going to fit a new spool holder as the original is broken also the fan was sticking though its better now I've oiled the bearings but I've have a 120x38 240V ac fan and connector I could fit to improve cooling.

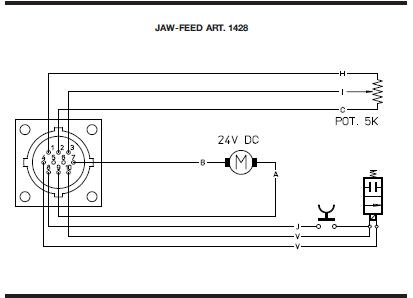

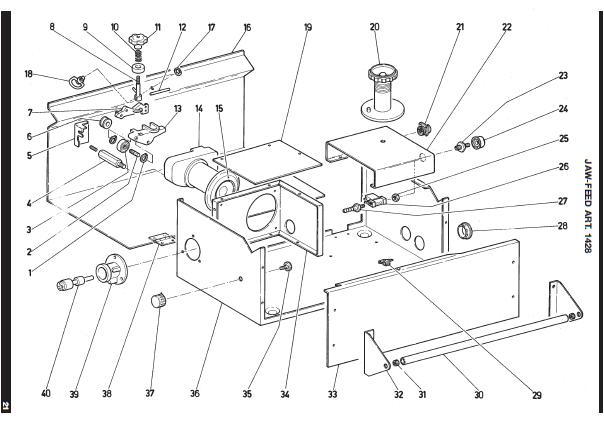

I'm in two minds what to do about the spool holder and euro torch as I'm getting a Cebora JawFeed (Art 1428) for a Jaguar 203 (Art 584) as it was cheaper than a spool holder and euro socket.

I could fit a 10 pin socket and a switch to change from internal to external wire feeder to the welder make up a cable and sit the wire feeder on top of my Combi and fit a Dinse socket input to the JawFeed.

Or I could fit the spool holder, gas solenoid, wire feeder and euro socket from the JawFeed to my welder. Presuming that the JawFeed motor and rollers are better than the Combi one.

If I keep the JawFeed as a separate feeder, I could fit a new original spool holder and a euro socket and use it for little spools of rarely used wire (gasless, ect) and connect the feeder for normal use, I have spare 240V ac gas solenoids I could fit if I do this.

I was going to convert the Snap on to dual polarity for gas/ gasless.

When I was looking at upgrading that welder BruceTS mentioned adding a 100000µF capacitor (C1) and 50Ω 25W bleed resistor (R1) to improve the welds produced and adding a second bridge rectifier to isolate the feed motor from the main smoothing capacitor to prevent wire feed run on while the capacitor is charged when the trigger is released and adding a 100µF capacitor (C2) across the feed motor to smooth the feed.

BruceTS's diagram.

The Combi has a two wire trigger and the contactor switches the + torch feed where as the Snap Mig has a single wire trigger switch and the contactor switches the - earth clamp.

Combi 888 Schematic

Will I still need to fit a second bridge rectifier?

What value capacitors would I need?

100000µF (0.1F) was mentioned but I've seen in other threads 47000µF caps mentioned as they don't increase the power output as I will be using the welder for car bodywork, exhausts and light fabrication like making bumper and side pod mounts out of tube for an old kart I'm rebuilding.

My welder doesn't have the thermal cut out warning light, Is it worth fitting one? Is it as simple as it looks, I presume its a 240V AC neon indicator wired in parallel with the thermostat. It would be simple for me to drill the front panel and fit one.

I was planning on fitting a euro torch, I got Trafimet Ergoplus 4m MB15 torch and was going to fit a new spool holder as the original is broken also the fan was sticking though its better now I've oiled the bearings but I've have a 120x38 240V ac fan and connector I could fit to improve cooling.

I'm in two minds what to do about the spool holder and euro torch as I'm getting a Cebora JawFeed (Art 1428) for a Jaguar 203 (Art 584) as it was cheaper than a spool holder and euro socket.

I could fit a 10 pin socket and a switch to change from internal to external wire feeder to the welder make up a cable and sit the wire feeder on top of my Combi and fit a Dinse socket input to the JawFeed.

Or I could fit the spool holder, gas solenoid, wire feeder and euro socket from the JawFeed to my welder. Presuming that the JawFeed motor and rollers are better than the Combi one.

If I keep the JawFeed as a separate feeder, I could fit a new original spool holder and a euro socket and use it for little spools of rarely used wire (gasless, ect) and connect the feeder for normal use, I have spare 240V ac gas solenoids I could fit if I do this.