MattF

Forum Supporter

- Messages

- 18,521

- Location

- South Yorkshire

This didn't start as a project, but it's turning into one.  Decided to fit a hook & loop backing pad, instead of using adhesive pads, so nicked one from a 5" angle grinder backing pad, same as pictured below. Contact adhesive used for the assembly.

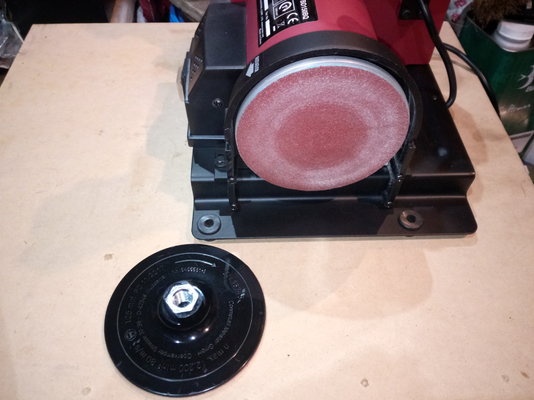

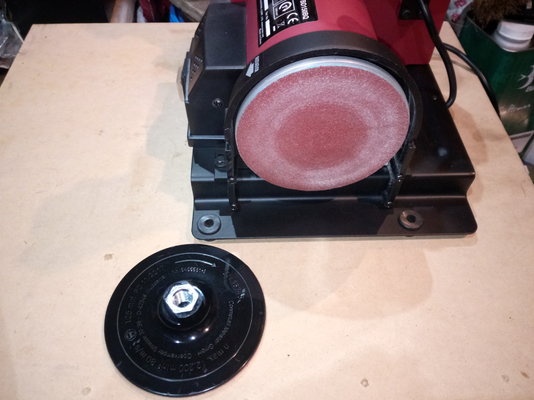

Decided to fit a hook & loop backing pad, instead of using adhesive pads, so nicked one from a 5" angle grinder backing pad, same as pictured below. Contact adhesive used for the assembly.

The foam backing was destroyed removing it from the backing pad, so replaced it with a thin piece of foam you get in those packs from the poundshops, B&M etc. Then needed to file the table to allow for the extra depth of the pads. Also, whilst I was faffing with it, decided to lap the table slightly, as the existing finish was extremely rough ground. If I'd known how far out from flat it was, I'd have started lapping with a far coarser grain sheet. Before & after:

Before & after:

Not perfect, but the plate would be wafer thin if I tried to make it perfect. Also had to sand the edge of the angle gauge for clearance.

Also had to sand the edge of the angle gauge for clearance.

Removed a washer from that pivot pin too. It was throwing it off kilter when clamped down. I assume that must just have been there for clearance with the table being so dished.

Also refitted the belt sander section, (I removed that ages ago as I used to cart this around for sanding down window blocks), and as soon as the belt was fitted, realised that one of the never before used bearings is shagged. So, I'll be replacing both of those. The table for that side is just as rough too, so I may end up lapping that also.

So, I'll be replacing both of those. The table for that side is just as rough too, so I may end up lapping that also.

Also need to make either some spacers or a new extractor cover for the bottom of the disc. May just glue some strips of rubber or something on there to give extra clearance for the original cover.

Decided to fit a hook & loop backing pad, instead of using adhesive pads, so nicked one from a 5" angle grinder backing pad, same as pictured below. Contact adhesive used for the assembly.

Decided to fit a hook & loop backing pad, instead of using adhesive pads, so nicked one from a 5" angle grinder backing pad, same as pictured below. Contact adhesive used for the assembly.

The foam backing was destroyed removing it from the backing pad, so replaced it with a thin piece of foam you get in those packs from the poundshops, B&M etc. Then needed to file the table to allow for the extra depth of the pads. Also, whilst I was faffing with it, decided to lap the table slightly, as the existing finish was extremely rough ground. If I'd known how far out from flat it was, I'd have started lapping with a far coarser grain sheet.

Before & after:

Before & after:

Not perfect, but the plate would be wafer thin if I tried to make it perfect.

Also had to sand the edge of the angle gauge for clearance.

Also had to sand the edge of the angle gauge for clearance.

Removed a washer from that pivot pin too. It was throwing it off kilter when clamped down. I assume that must just have been there for clearance with the table being so dished.

Also refitted the belt sander section, (I removed that ages ago as I used to cart this around for sanding down window blocks), and as soon as the belt was fitted, realised that one of the never before used bearings is shagged.

So, I'll be replacing both of those. The table for that side is just as rough too, so I may end up lapping that also.

So, I'll be replacing both of those. The table for that side is just as rough too, so I may end up lapping that also.

Also need to make either some spacers or a new extractor cover for the bottom of the disc. May just glue some strips of rubber or something on there to give extra clearance for the original cover.