Been meaning to do a mod and repair to my shaper for ages now, finally got around to it. In a former life someone had snapped off one of the gib adjusting screws on the top slide. It was broken off fairly deep in the tapped hole and had damaged the thread as well. No chance of welding anything to it, at least with my welding skills. Tried drilling but nothing seemed to touch it. Attempts at drifting it round with a slim punch also failed. The professional way would be spark erosion. So hunted high and low, even looked under the bed, alas not be a professional did not have a spark eroder.

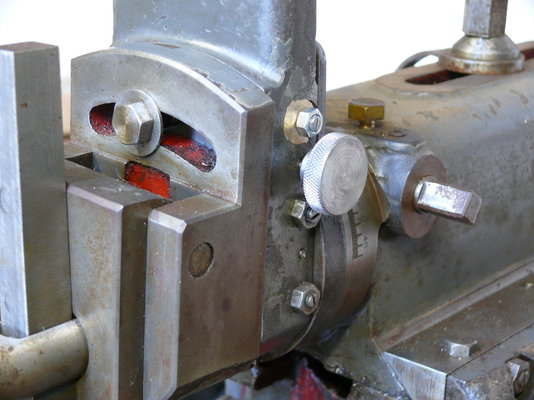

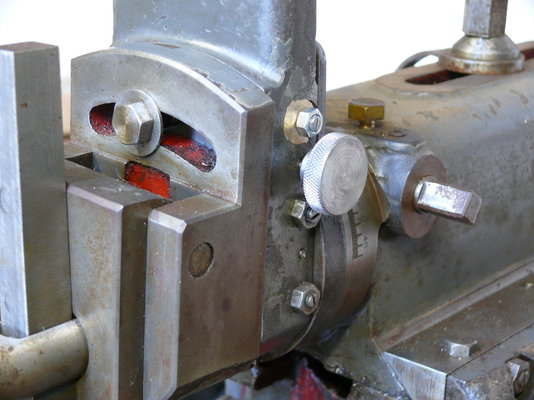

Only option was the tried and trusted GBS method (gash, bash 'nd slash). Mounted the smallest carbide tipped hole saw I had minus the centre drill in the mill and went for it. Had to drill off centre as I did not want to break out into the machined face. A 3/8” bsp pipe tap put some threads in the hole and a piece of brass bar was threaded and glued in with some ex nato loctite I had ( well past it's use by date, but still seems to work). Cleaned up the dovetail, located the existing holes with the dro and drilled/tapped for a new screw. A bit more gbs on an m6 set screw made a new adjuster. Also did the mod and drilled a new hole for a slide locking screw. Been meaning to do that for years.

Only option was the tried and trusted GBS method (gash, bash 'nd slash). Mounted the smallest carbide tipped hole saw I had minus the centre drill in the mill and went for it. Had to drill off centre as I did not want to break out into the machined face. A 3/8” bsp pipe tap put some threads in the hole and a piece of brass bar was threaded and glued in with some ex nato loctite I had ( well past it's use by date, but still seems to work). Cleaned up the dovetail, located the existing holes with the dro and drilled/tapped for a new screw. A bit more gbs on an m6 set screw made a new adjuster. Also did the mod and drilled a new hole for a slide locking screw. Been meaning to do that for years.