I have a fly press and a few punches, and have been looking on Ebay for any bending tools, and I must be a skinflint.

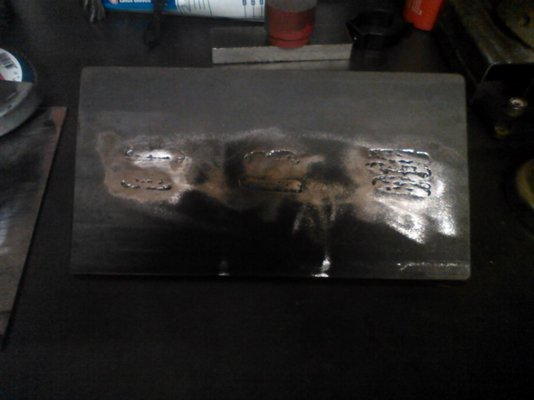

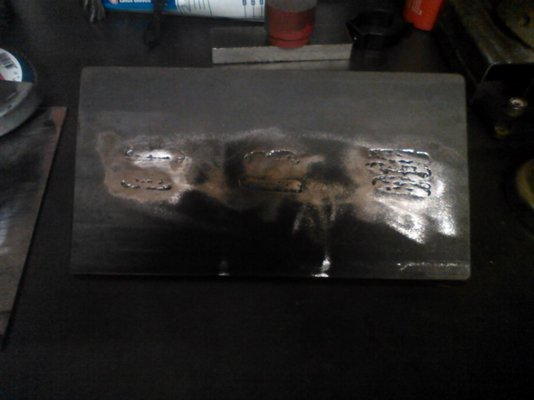

So started to make own, initially with a 9 inch length of 19mm bar (sorry for mixed measurements. Welded it down to some 5 mm plate and clamped in the mill and cut my V. I only had 90 degree cutters so could not do the normal 88 degrees to allow for spring back but, thinking of placing a further cut in the base of the V making it flat bottomed around 5 mm wide. Will see how it goes.

I was going to use my Mig to secure the two bits together but when plugged in blows the RCD after approx 2 minutes, so I need to dry the thing out, assuming it is suffering from damp. So I ended up using the Tig at 140 amps, to counter the distortion caused by the welds I heated up the underside of the plate in the same points as the welds on top, the idea being to pull it back to flat! It worked quite well, I used the flap disks to remove any high points when all cooled.

I have yet to make the blade for it and may struggle milling this to shape. Anyone know what the angle of the blade normally is, I am guessing at the point being around 70 degrees?

Any pointers?

Adrian

So started to make own, initially with a 9 inch length of 19mm bar (sorry for mixed measurements. Welded it down to some 5 mm plate and clamped in the mill and cut my V. I only had 90 degree cutters so could not do the normal 88 degrees to allow for spring back but, thinking of placing a further cut in the base of the V making it flat bottomed around 5 mm wide. Will see how it goes.

I was going to use my Mig to secure the two bits together but when plugged in blows the RCD after approx 2 minutes, so I need to dry the thing out, assuming it is suffering from damp. So I ended up using the Tig at 140 amps, to counter the distortion caused by the welds I heated up the underside of the plate in the same points as the welds on top, the idea being to pull it back to flat! It worked quite well, I used the flap disks to remove any high points when all cooled.

I have yet to make the blade for it and may struggle milling this to shape. Anyone know what the angle of the blade normally is, I am guessing at the point being around 70 degrees?

Any pointers?

Adrian