MattH

Member

- Messages

- 4,515

- Location

- Cornwall

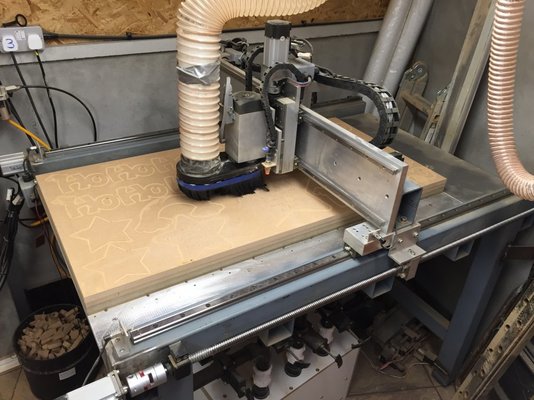

I'm in the design phase of building a new CNC gantry type Router to replace/augment my current machine. The existing machine was built using 80mm SHS and is running well. However when I try to push the cutting speed I get a lot of vibration and flex.

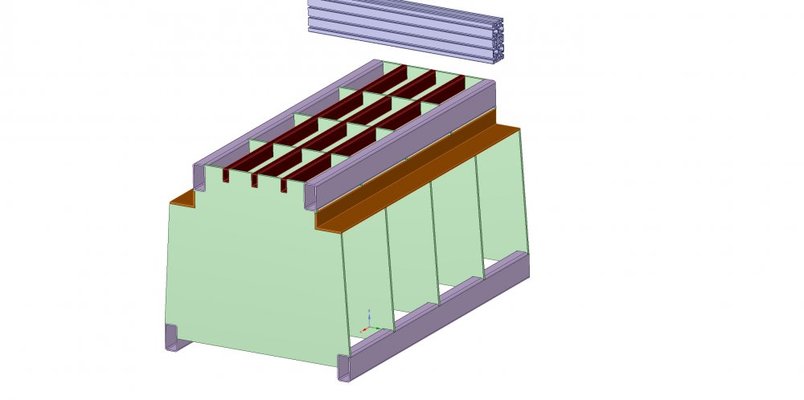

The new frame needs to be built in such a way as to reduce flex and vibration. So key factors here are mass and rigidity.

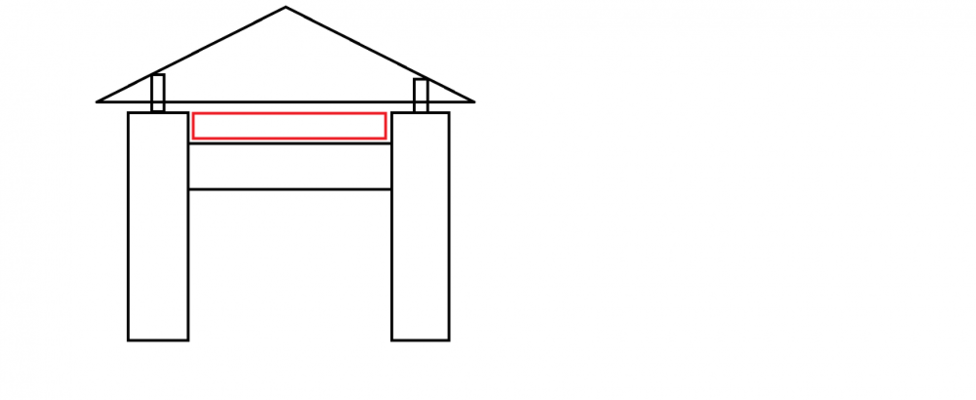

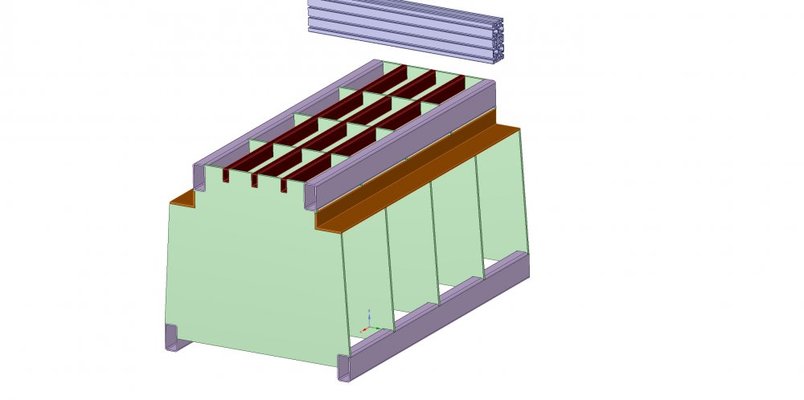

The machine will have a 600mmx1200mm cutting area and will be approx. 900mm wide and 900mm tall.

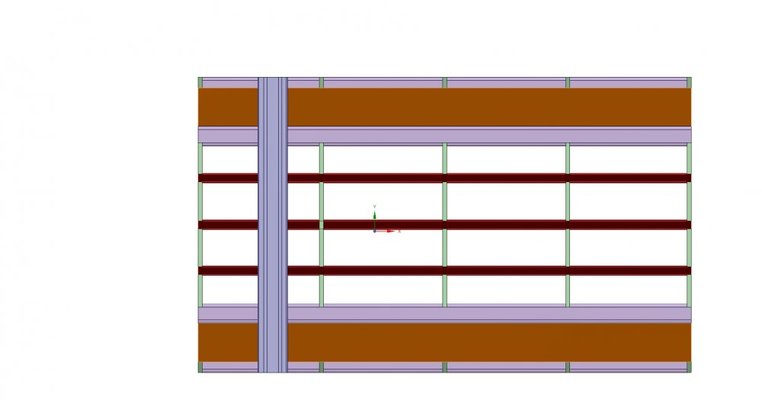

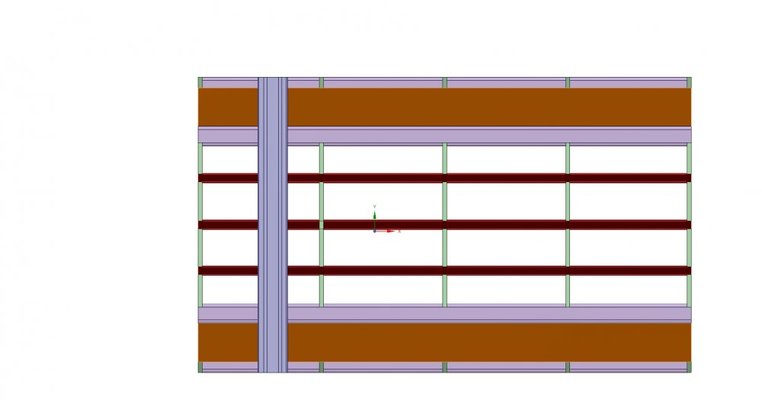

In the renders below the cross section plates are going to be 12mm laser cut steel, the Large box sections are 120mmx60mmx5mm RHS, the small box section is 60mmx30mmx3mm and the angle is 125mmx75xx10mm.

I will add some more 60x30 along the sides of the machine and perhaps the bottom as well.

Thoughts? Opinions? Flames?

For those interested the mechanicals will be X axis 25mm Hiwin rails and 1.25 Mod helical R&P, Y axis 20mm Hiwin rails and 1.25 Mod helical R&P, Z axis 15mm Hiwin Rails and 10mm 4mm Pitch THK C3 ballscrew. 3HP 24KRPM ATC Spindle, 400W AC Brushless servos (Leadshine EL5), CMSIO-IP/6S Controller with Mach3.

Rapids on X and Y are 24M/Min, cutting: 5M/Min engraving and 15M/Min profiling (all in wood).

The new frame needs to be built in such a way as to reduce flex and vibration. So key factors here are mass and rigidity.

The machine will have a 600mmx1200mm cutting area and will be approx. 900mm wide and 900mm tall.

In the renders below the cross section plates are going to be 12mm laser cut steel, the Large box sections are 120mmx60mmx5mm RHS, the small box section is 60mmx30mmx3mm and the angle is 125mmx75xx10mm.

I will add some more 60x30 along the sides of the machine and perhaps the bottom as well.

Thoughts? Opinions? Flames?

For those interested the mechanicals will be X axis 25mm Hiwin rails and 1.25 Mod helical R&P, Y axis 20mm Hiwin rails and 1.25 Mod helical R&P, Z axis 15mm Hiwin Rails and 10mm 4mm Pitch THK C3 ballscrew. 3HP 24KRPM ATC Spindle, 400W AC Brushless servos (Leadshine EL5), CMSIO-IP/6S Controller with Mach3.

Rapids on X and Y are 24M/Min, cutting: 5M/Min engraving and 15M/Min profiling (all in wood).