anth510

Member

- Messages

- 17

Hi all, just joined up, here's my intro thread:

http://www.mig-welding.co.uk/forum/showthread.php?t=35373

I'm currently making a new lower alternator mount, here it is before welding:

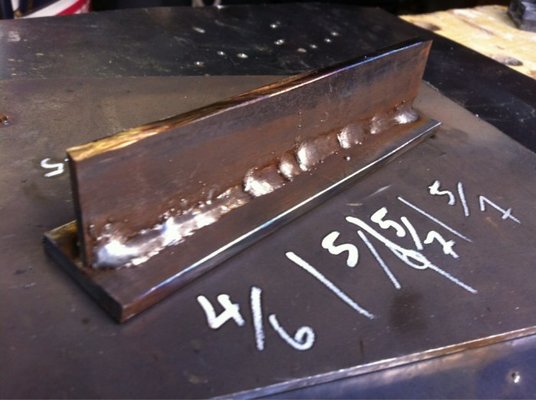

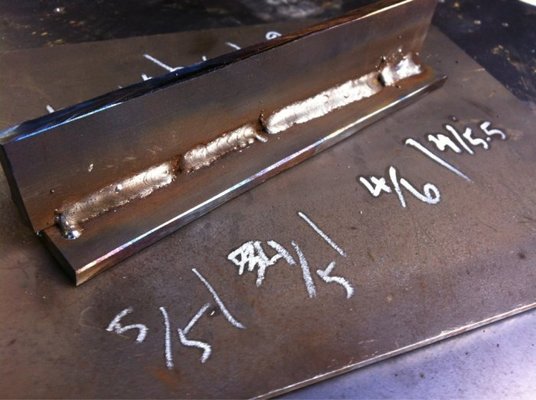

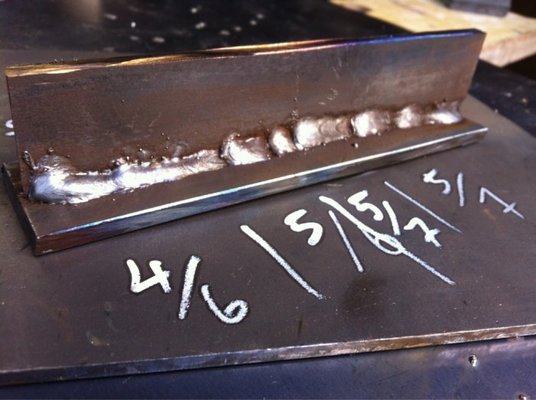

I comprises of 3 parts. A lower mounting plate, and two vertical tabs. I need to weld those two vertical tabs onto the bottom mounting plate, and then probably add some sort of a gusset for strength between them. The material is 5mm steel.

I am using a Uni Mig 180 amp mig welder, with .08mm wire and BOC Argoshield Light gas.

My problem is that I can get nice welds on 5mm steel when doing practice runs on flat sheets, but then using the same settings on a T joint doesn't give me the same results. I welded the piece in the photo above last night and wasn't happy with it, plus I welded it all without letting it cool down between runs so it's slightly warped, therefore I'll be making another one!

I noticed that at times it appeared I wasn't getting enough penetration, the welds were tall and not "sticking" to both pieces of metal at some points (more heat?), but then when I get near the edges of the piece (end of the run) the metal goes bright red and starts to melt (less heat?) This is where I'm confused. Should I pull the welder slightly further away from the piece at the end of the run?

Any help is appreciated

http://www.mig-welding.co.uk/forum/showthread.php?t=35373

I'm currently making a new lower alternator mount, here it is before welding:

I comprises of 3 parts. A lower mounting plate, and two vertical tabs. I need to weld those two vertical tabs onto the bottom mounting plate, and then probably add some sort of a gusset for strength between them. The material is 5mm steel.

I am using a Uni Mig 180 amp mig welder, with .08mm wire and BOC Argoshield Light gas.

My problem is that I can get nice welds on 5mm steel when doing practice runs on flat sheets, but then using the same settings on a T joint doesn't give me the same results. I welded the piece in the photo above last night and wasn't happy with it, plus I welded it all without letting it cool down between runs so it's slightly warped, therefore I'll be making another one!

I noticed that at times it appeared I wasn't getting enough penetration, the welds were tall and not "sticking" to both pieces of metal at some points (more heat?), but then when I get near the edges of the piece (end of the run) the metal goes bright red and starts to melt (less heat?) This is where I'm confused. Should I pull the welder slightly further away from the piece at the end of the run?

Any help is appreciated