You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Testing diodes

- Thread starter swedge

- Start date

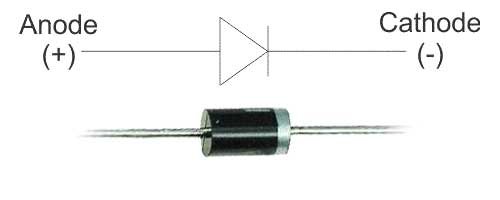

Some dmms may not provide enough current/ voltage to drive the diode into conduction. Most have a diode test setting on them, use that.

If on a dmm, without it, you get a reading one way and infinite resistance the other then fine, if you don't get a reading both ways then you may need another meter or another diode, if you get a reading both ways then you need a new diode.

But when testing isolate the diode from the rest of the circuitry.

If on a dmm, without it, you get a reading one way and infinite resistance the other then fine, if you don't get a reading both ways then you may need another meter or another diode, if you get a reading both ways then you need a new diode.

But when testing isolate the diode from the rest of the circuitry.

Jim Davey

R H Davey Welding Supplies Ltd

- Messages

- 5,736

- Location

- Southampton

Yes,all the diodes in the same plate will be the same orientation.

However, it's best to disconnect the rectifier inputs and outputs as the other components in the machine can give you false readings if you leave the rectifier in circuit.

Put your DMM into diode test, you souls see OL one way, and around 400 the other way.

If you get an open circuit both ways or conduction both ways then you need s new rectifier.

However, it's best to disconnect the rectifier inputs and outputs as the other components in the machine can give you false readings if you leave the rectifier in circuit.

Put your DMM into diode test, you souls see OL one way, and around 400 the other way.

If you get an open circuit both ways or conduction both ways then you need s new rectifier.

mike 109444

Member

- Messages

- 4,775

The problem with trying to meter the diodes is that each group of diodes share a common connection point at each end. One common end is the plate they are pressed in to and the other is the ring (washer) that they are spot welded to. T try and separate/isolate one of them would mean pressing out the plate or cutting along the lead to de-spot weld. I think your original post said you were finding your welder was failing/loosing power on it's top setting after a while of welding. I looked over the pics of your machine but could not see anything amiss such as hot signs on the cables at the power selector or at the transformer, broken diodes or poor/burnt connections on diode pack. So could not make any suggestions at the time.

Having thought about it, on check to do would be to run the welder on top setting making some beads on scrap, then disconnect from mains (unplug!) and go round those bolt connections on the diode pack and any other connections in the circuit touching and feeling for a hot spot. Could be you have a poor connection somewhere in the circuit that is breaking down under load. Note that things in there will be warm any way from use.

The voltage figures you posted for the voltage range looked about right (compare the top one with the data plate on your machine)

A visual inspection with a very good light of the diode pack may show up a cracked diode or one of the leads to a diode as being broken.

At the moment you have a welder that "works" IF you start to pull the diode pack apart you are most likely to snap at least one !

From cold do you get the same readings on the top setting and does that drop when the fault condition occurs?

Have you checked the mains plug for poor connection (re make the connections if unsure)

Have you checked the work ground clamp to it's cable connection ? They do come loose.

Check the work ground lead socket, is it a loose fit ?

The checks above are to avoid taking the diode pack apart as a first thing !!

Having thought about it, on check to do would be to run the welder on top setting making some beads on scrap, then disconnect from mains (unplug!) and go round those bolt connections on the diode pack and any other connections in the circuit touching and feeling for a hot spot. Could be you have a poor connection somewhere in the circuit that is breaking down under load. Note that things in there will be warm any way from use.

The voltage figures you posted for the voltage range looked about right (compare the top one with the data plate on your machine)

A visual inspection with a very good light of the diode pack may show up a cracked diode or one of the leads to a diode as being broken.

At the moment you have a welder that "works" IF you start to pull the diode pack apart you are most likely to snap at least one !

From cold do you get the same readings on the top setting and does that drop when the fault condition occurs?

Have you checked the mains plug for poor connection (re make the connections if unsure)

Have you checked the work ground clamp to it's cable connection ? They do come loose.

Check the work ground lead socket, is it a loose fit ?

The checks above are to avoid taking the diode pack apart as a first thing !!

mike 109444

Member

- Messages

- 4,775

ps IF you do take the pack apart then note in which order each spacer/insulator goes cos get it wrong and you will cause a short.

Thanks for the the replies, I'll test it again today since it will definitely be cold and see if the readings are the same on the highest setting

I'll also have another look over the diodes and like you said the last thing I want to do is take it all apart, I work in a mechanical/electrical engineers so could have them take a look at it as my electrical experience is limited (I'm more of a hammer and weld kinda guy lol)

Would the rectifier be a replaceable whole unit?

Would it need to be from a cebora dealer?

I'll also have another look over the diodes and like you said the last thing I want to do is take it all apart, I work in a mechanical/electrical engineers so could have them take a look at it as my electrical experience is limited (I'm more of a hammer and weld kinda guy lol)

Would the rectifier be a replaceable whole unit?

Would it need to be from a cebora dealer?

WorkshopChris

Member

- Messages

- 5,049

- Location

- South East Essex

Yes the unit would best be changes as a complete unit.Would the rectifier be a replaceable whole unit?

Would it need to be from a cebora dealer?

You dont need to go back to Cebora any welding supply company who have specialist who repair machines, should be able to source a generic replacement.

Removed the rectifier and gave it another look over, none of the wires that come from the diode to the centre posts are broken

The wires are soldered on and are solid wire so I can't test them with my multimeter as I don't fancy taking them off

I ran a continuity test from the top of the diode to the centre post and they all beeped, dunno if that means anything but thought I'd do that while I was there

I made sure all bolts were tight and fired it back up and still the same

I've took some more pics

The wires are soldered on and are solid wire so I can't test them with my multimeter as I don't fancy taking them off

I ran a continuity test from the top of the diode to the centre post and they all beeped, dunno if that means anything but thought I'd do that while I was there

I made sure all bolts were tight and fired it back up and still the same

I've took some more pics

-

IMG_4580.JPG436.4 KB · Views: 523

IMG_4580.JPG436.4 KB · Views: 523 -

IMG_4581.JPG235.4 KB · Views: 271

IMG_4581.JPG235.4 KB · Views: 271 -

IMG_4582.JPG226.3 KB · Views: 229

IMG_4582.JPG226.3 KB · Views: 229 -

IMG_4583.JPG205 KB · Views: 221

IMG_4583.JPG205 KB · Views: 221 -

IMG_4584.JPG241.1 KB · Views: 222

IMG_4584.JPG241.1 KB · Views: 222 -

IMG_4585.JPG263.8 KB · Views: 248

IMG_4585.JPG263.8 KB · Views: 248 -

IMG_4586.JPG235.1 KB · Views: 256

IMG_4586.JPG235.1 KB · Views: 256 -

IMG_4587.JPG225.6 KB · Views: 230

IMG_4587.JPG225.6 KB · Views: 230 -

IMG_4588.JPG227.8 KB · Views: 224

IMG_4588.JPG227.8 KB · Views: 224 -

IMG_4589.JPG218.9 KB · Views: 295

IMG_4589.JPG218.9 KB · Views: 295

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,440

- Location

- France, Brittany.

what problems are you having with your machine?