gaz1

Member

- Messages

- 19,010

- Location

- westyorkshire

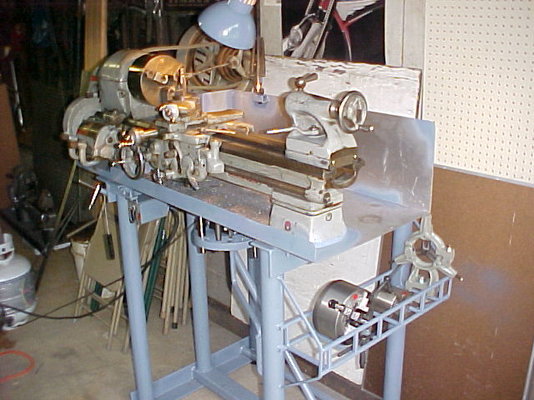

ive just bought myself a lathe and now im looking at securing it to something strong rather than it being pinched from the shed the area i want the lathe in is displayed in the photos below

the door is a steel factory fire door and fastened with coach bolts

http://www.mig-welding.co.uk/forum/...rkshop-security-door.20688/page-2#post-476721

also the welding table has been moved from the right to the left and thats going to be at the side of the wood burner rocket

i know some of the heat will transfere into the steel table

my shed is not brilliant at the moment still sorting things out and throwing out what i dont want the red box i hate with a vengence but im also looking to secure this somewhere so thought id ask you guys where best to put it and secure it as still need access to it

it cant go under the welding table as thats my store areas as well and i also need to find space for the pillar drill will not fit under the steel shelving at end of shed to the work top

the vices im considering using the tilt and slide under the welding table method but im also considering using the end of the table as a bending machine area or rolling machine on its side about 30" high

the door is a steel factory fire door and fastened with coach bolts

http://www.mig-welding.co.uk/forum/...rkshop-security-door.20688/page-2#post-476721

also the welding table has been moved from the right to the left and thats going to be at the side of the wood burner rocket

i know some of the heat will transfere into the steel table

my shed is not brilliant at the moment still sorting things out and throwing out what i dont want the red box i hate with a vengence but im also looking to secure this somewhere so thought id ask you guys where best to put it and secure it as still need access to it

it cant go under the welding table as thats my store areas as well and i also need to find space for the pillar drill will not fit under the steel shelving at end of shed to the work top

the vices im considering using the tilt and slide under the welding table method but im also considering using the end of the table as a bending machine area or rolling machine on its side about 30" high

That space is far too crammed to be useful as is. Sort some proper storage, whether it be shelving or cabinets, along one wall and go from there.

That space is far too crammed to be useful as is. Sort some proper storage, whether it be shelving or cabinets, along one wall and go from there.

needless to say i still have it and nothing said

needless to say i still have it and nothing said