prepman

Forum Supporter

- Messages

- 2,693

- Location

- Gwynedd UK

I've recently bought a 2nd hand faulty welder off eBay to repair, a Draper MW151AT.

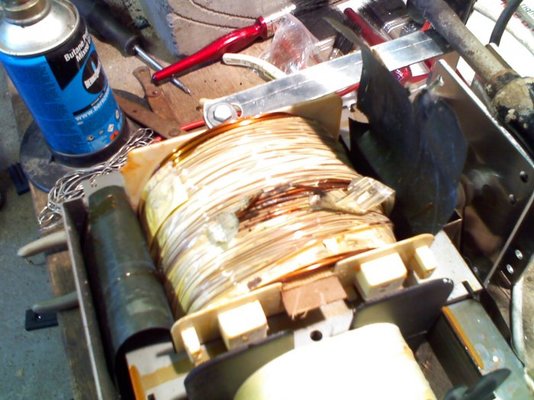

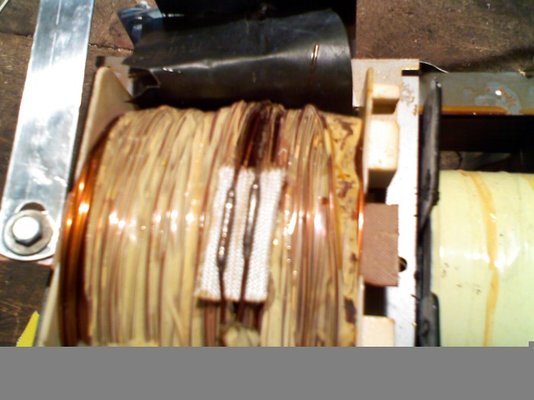

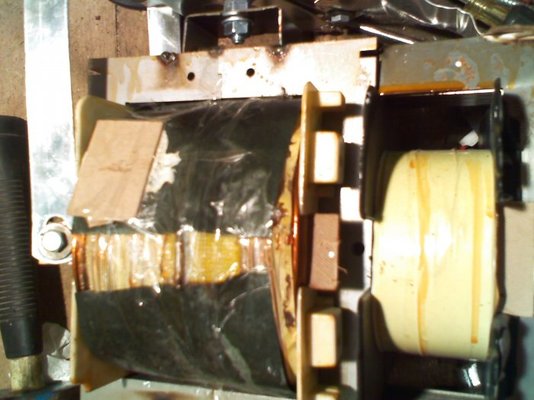

I've found that the external windings of the primary transformer are damaged. But only 2 turns. It looks as if the the set has fallen over on to it's side whilst powered up and a foreign metal body has got impaled in the windings as it shifted against the internal centre panel (the one carrying the wirefeed assembly). I reckon the mag field has pulled the panel onto the windings each time it was under load, from the description of the seller. Only blew fuses when attempting to weld.

The question is? Best way to repair. I've thought of splitting the core and rewinding the damaged tapping. But there's only 2 turns on the surface broken all the rest are fine and meter out OK.

The easiest/cheapest way would be to re-join the turns, tape and re-lacquer. I can machine copper barrel connectors or whatever on the lathe.

Question......

Has anyone done this before? If so how did you re-join? Butt solder? Lap solder? Crimps? Rewind?

I've found that the external windings of the primary transformer are damaged. But only 2 turns. It looks as if the the set has fallen over on to it's side whilst powered up and a foreign metal body has got impaled in the windings as it shifted against the internal centre panel (the one carrying the wirefeed assembly). I reckon the mag field has pulled the panel onto the windings each time it was under load, from the description of the seller. Only blew fuses when attempting to weld.

The question is? Best way to repair. I've thought of splitting the core and rewinding the damaged tapping. But there's only 2 turns on the surface broken all the rest are fine and meter out OK.

The easiest/cheapest way would be to re-join the turns, tape and re-lacquer. I can machine copper barrel connectors or whatever on the lathe.

Question......

Has anyone done this before? If so how did you re-join? Butt solder? Lap solder? Crimps? Rewind?