carl0s

Member

- Messages

- 378

- Location

- Kelsall

Hi.

The unloader / bleeder is open all the time, meaning the compressor is struggling to fill the tank. It's been sat about 20 months since house move, now I'm finally getting round to plumbing it all in again.

It used to hiss out of the unloader for the first 20 seconds or so, then that would close and it would fill.

Now it's just blowing out there all the time.

Once turned off, it's OK - so it's not an issue with the one way valve into the tank. Is just that the unloader can't be closed during fill like it should be.

I can't see how it is supposed to work though.

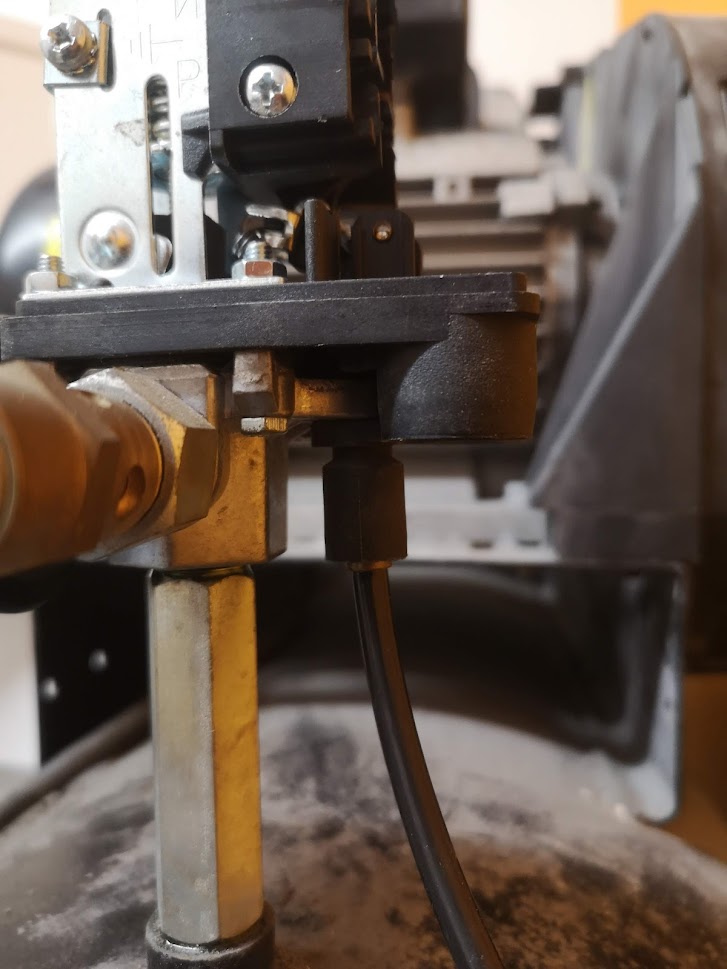

The compressor (SIP 150 3hp) uses a flexi hose for this part. On the tank side it's a compression olive with a tube-insert.

On the valve, I can see a brass ring that can be moved up and down - which makes me think it must be a push-to-release thing, but I am trying with needle-nose pliers and not having any luck.

I have ordered a replacement valve from Amazon last night, but that valve looks to have a compression-olive fitting, and I don't have a tube-insert for this end. At least I don't think so although I can't get the end off to see. I might be able to buy a brass shed-bolt from Toolstation and make one on the lathe, although I've only used the lathe once or twice so far and I'm pretty inexperienced. This is quite a small insert. Of course I could just skip the insert and try a compression olive straight onto the flexi pipe.

Before I pull it all apart and possibly break it, does anyone have any ideas, and maybe suggestions for how to fix the existing valve?

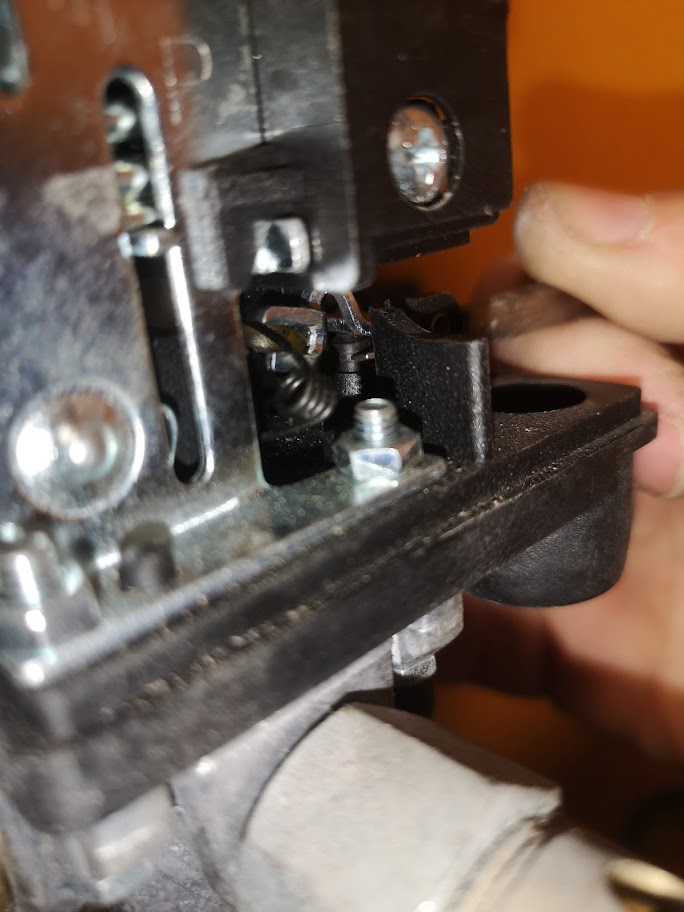

I can see some kind of hat thing on the end of the unloader pipe under a lever inside, but it doesn't seem to do much. I can lift it with a screwdriver but it's basically loose and just sat there. I can blow through the pipe no matter what I fiddle with at the valve side.

Here are some photos.

The unloader / bleeder is open all the time, meaning the compressor is struggling to fill the tank. It's been sat about 20 months since house move, now I'm finally getting round to plumbing it all in again.

It used to hiss out of the unloader for the first 20 seconds or so, then that would close and it would fill.

Now it's just blowing out there all the time.

Once turned off, it's OK - so it's not an issue with the one way valve into the tank. Is just that the unloader can't be closed during fill like it should be.

I can't see how it is supposed to work though.

The compressor (SIP 150 3hp) uses a flexi hose for this part. On the tank side it's a compression olive with a tube-insert.

On the valve, I can see a brass ring that can be moved up and down - which makes me think it must be a push-to-release thing, but I am trying with needle-nose pliers and not having any luck.

I have ordered a replacement valve from Amazon last night, but that valve looks to have a compression-olive fitting, and I don't have a tube-insert for this end. At least I don't think so although I can't get the end off to see. I might be able to buy a brass shed-bolt from Toolstation and make one on the lathe, although I've only used the lathe once or twice so far and I'm pretty inexperienced. This is quite a small insert. Of course I could just skip the insert and try a compression olive straight onto the flexi pipe.

Before I pull it all apart and possibly break it, does anyone have any ideas, and maybe suggestions for how to fix the existing valve?

I can see some kind of hat thing on the end of the unloader pipe under a lever inside, but it doesn't seem to do much. I can lift it with a screwdriver but it's basically loose and just sat there. I can blow through the pipe no matter what I fiddle with at the valve side.

Here are some photos.