chrisg3103

Forum Supporter

- Messages

- 791

well someones been telling fibs  chap i bought the lathe from said he had never used the screwcutting gearbox but it worked fine. the selector was just stiff from lack of use, had a look in the case, all the teeth on the gears good enough for me.

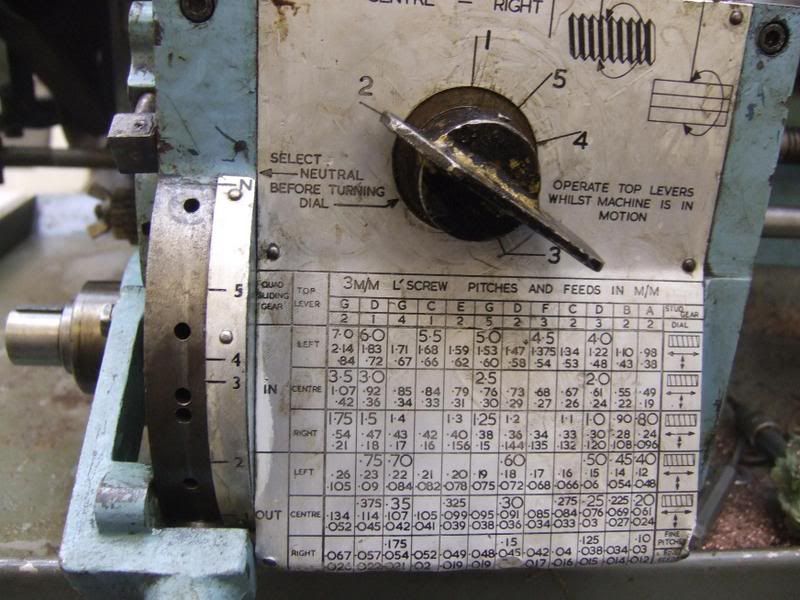

chap i bought the lathe from said he had never used the screwcutting gearbox but it worked fine. the selector was just stiff from lack of use, had a look in the case, all the teeth on the gears good enough for me.

then i get it back and look a little deeper.....

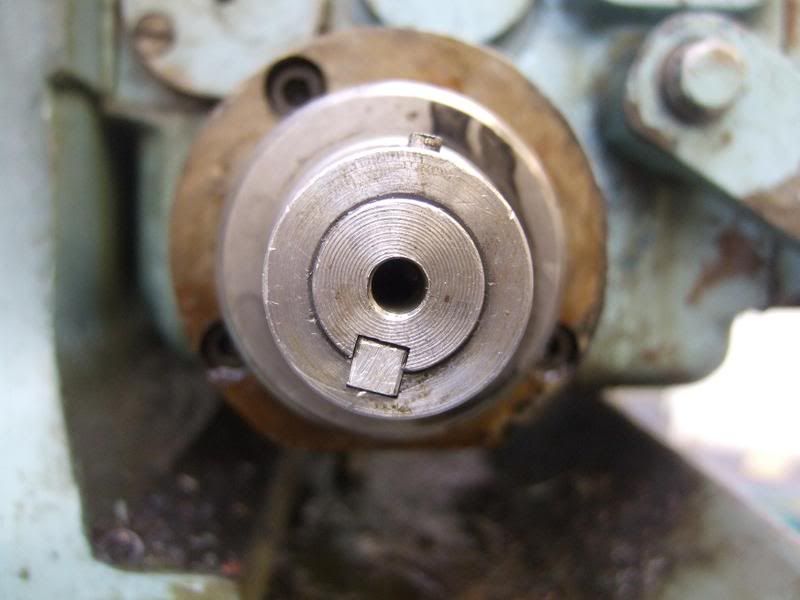

the key the feed shaft/lead shaft selector gear slides along was bent like a bannana! the key also holds the gear that transfers the power to that shaft so why nothing was turning at all

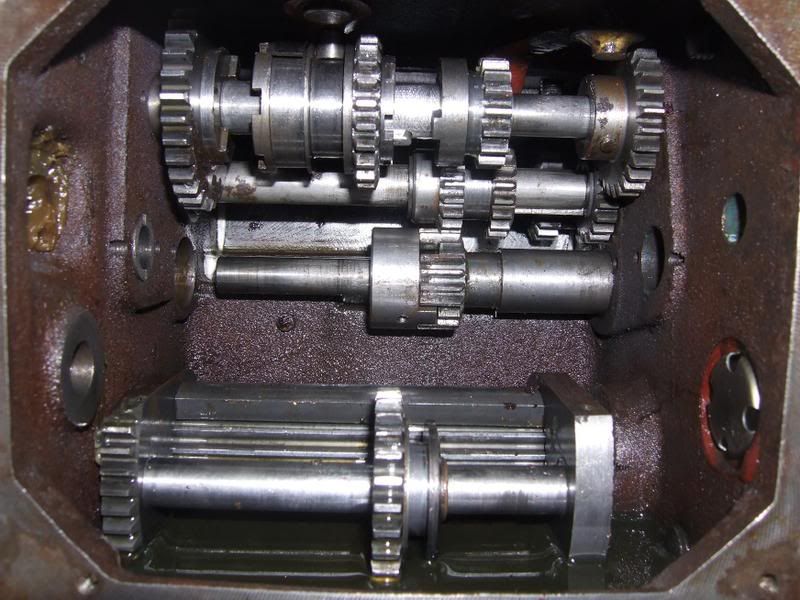

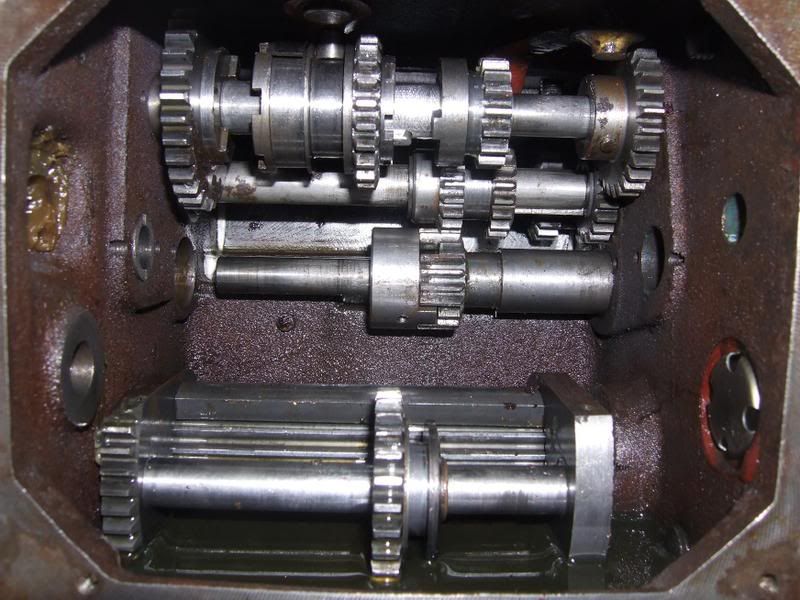

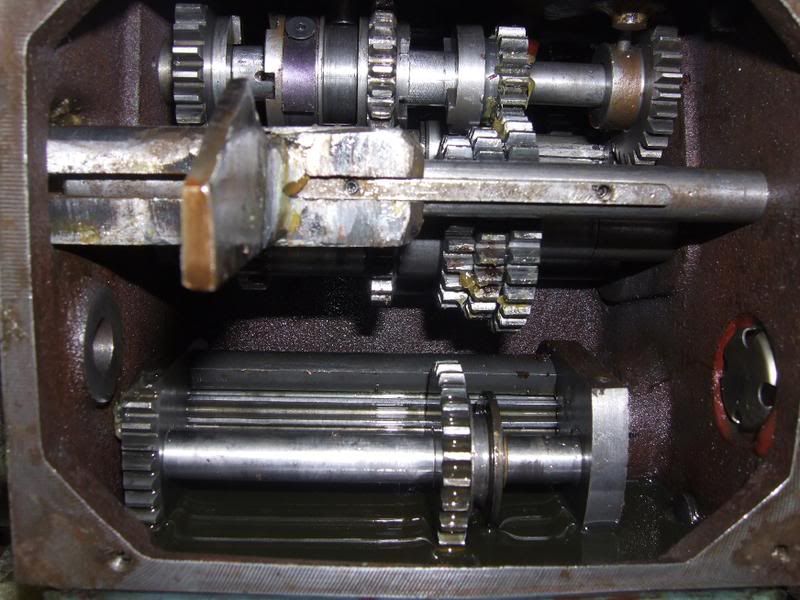

so one empty gearbox

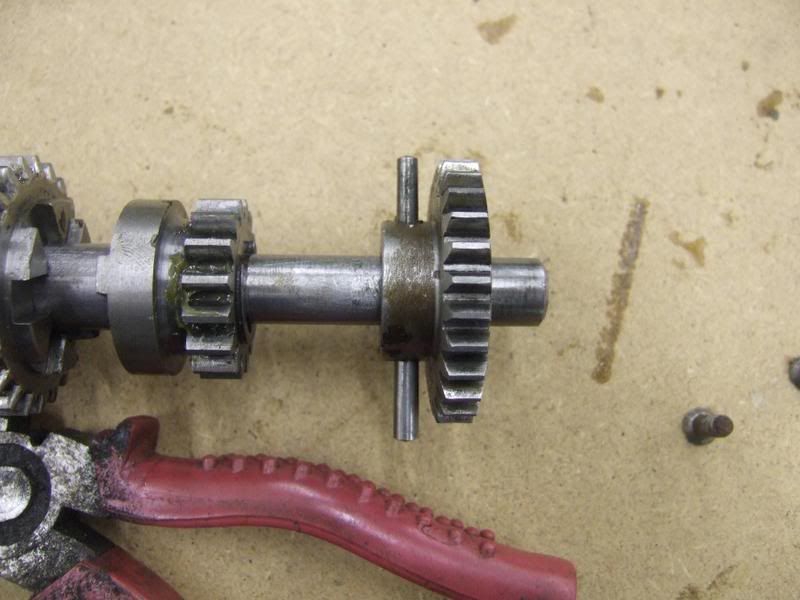

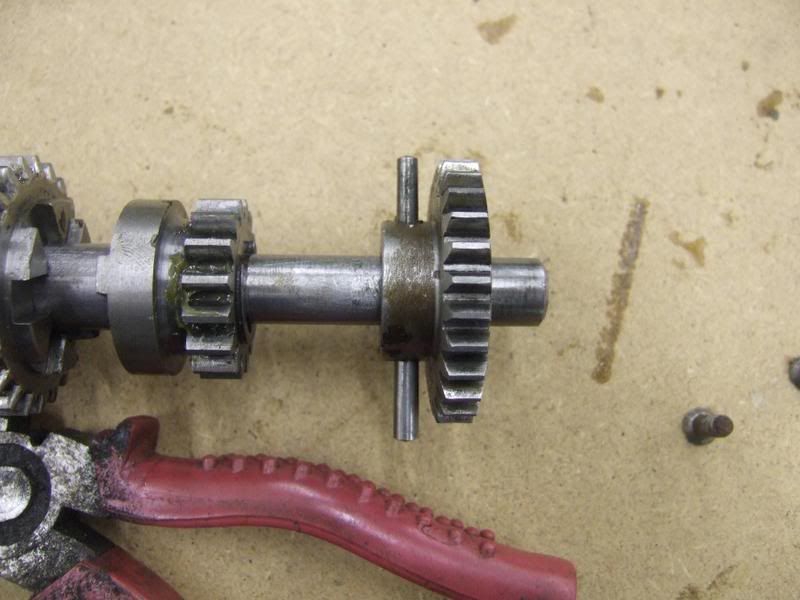

and lots of bits

i hammered and filed the key flat again but it had damaged itself and the shaft quite a bit, looks like the first job for the lathe is to turn itself a new shaft

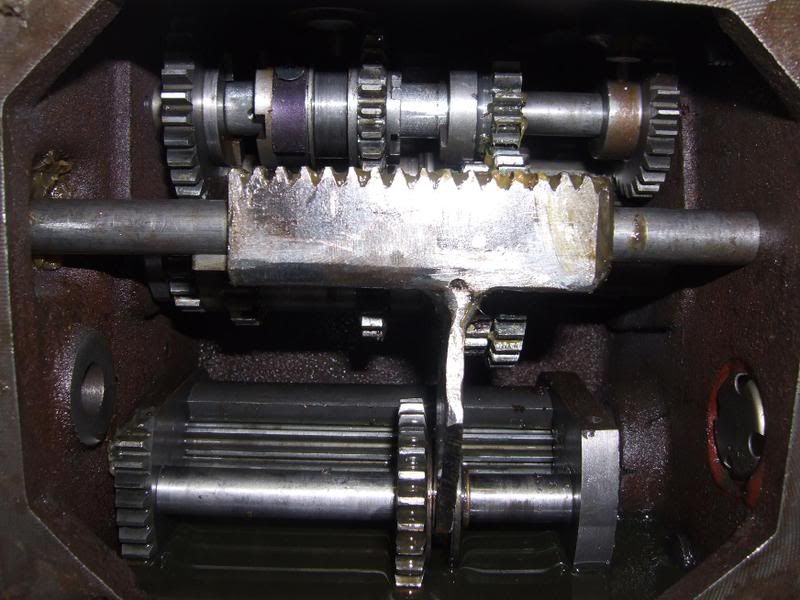

back in the gearbox

can just see the now straight key and the gear that slides along it, as well as the power transfer gear thats also held by the key

another problem was the other selector mechanism was a bit siezed, so striped it

can just see the damage by the detent holes, a quick file and a polish the thing was sliding again

the old taper pin took a beating coming out so had to fit a new one, by sheer jammy luck i had bought a box of 3/16'' taper pins the month before

needs trimming....

shaft back in and the selectors all selecting

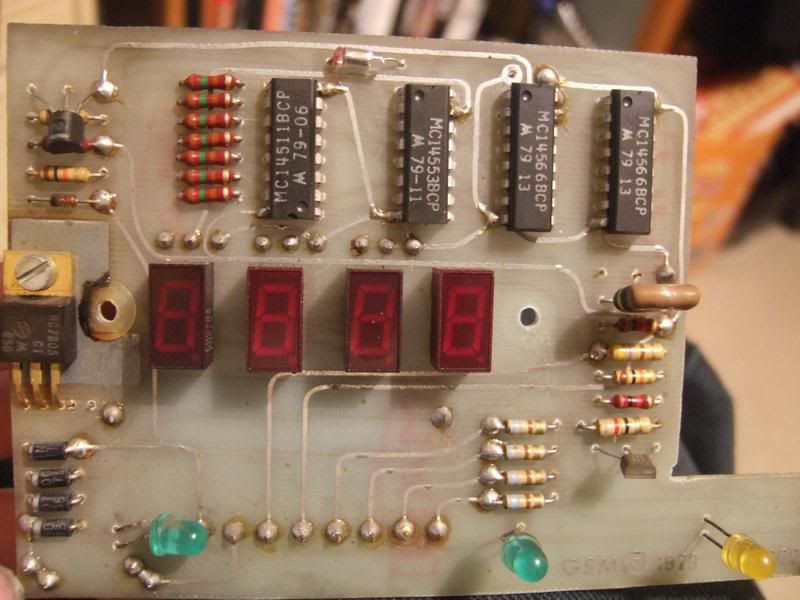

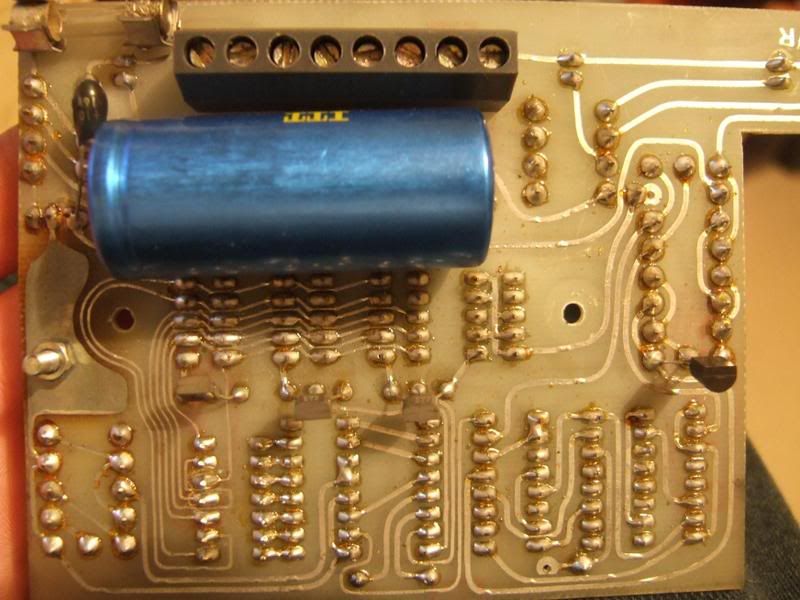

as far as i got before i needed food. not so peeved seeing as it was fixable, but ill be inspecting more closly in the future! still to figure out the tachometer and look into the huge amount of backlash on the top slide.

chap i bought the lathe from said he had never used the screwcutting gearbox but it worked fine. the selector was just stiff from lack of use, had a look in the case, all the teeth on the gears good enough for me.

chap i bought the lathe from said he had never used the screwcutting gearbox but it worked fine. the selector was just stiff from lack of use, had a look in the case, all the teeth on the gears good enough for me.then i get it back and look a little deeper.....

the key the feed shaft/lead shaft selector gear slides along was bent like a bannana! the key also holds the gear that transfers the power to that shaft so why nothing was turning at all

so one empty gearbox

and lots of bits

i hammered and filed the key flat again but it had damaged itself and the shaft quite a bit, looks like the first job for the lathe is to turn itself a new shaft

back in the gearbox

can just see the now straight key and the gear that slides along it, as well as the power transfer gear thats also held by the key

another problem was the other selector mechanism was a bit siezed, so striped it

can just see the damage by the detent holes, a quick file and a polish the thing was sliding again

the old taper pin took a beating coming out so had to fit a new one, by sheer jammy luck i had bought a box of 3/16'' taper pins the month before

needs trimming....

shaft back in and the selectors all selecting

as far as i got before i needed food. not so peeved seeing as it was fixable, but ill be inspecting more closly in the future! still to figure out the tachometer and look into the huge amount of backlash on the top slide.

not so bothered about screwcutting

not so bothered about screwcutting

need to go buy a deerstalker hat and a pipe me thinks

need to go buy a deerstalker hat and a pipe me thinks