Hey All,

Just wondering if anyone has a sort of cheat sheet to get me in the ballpark for settings on different materials, thicknesses and wire sizes?

E.g. something like this https://www.scribd.com/document/407610601/242-MIG-Settings-Chart#

Ideally in metric, up to at least 250a and 1.2mm wire for mild steel with mixed gas.

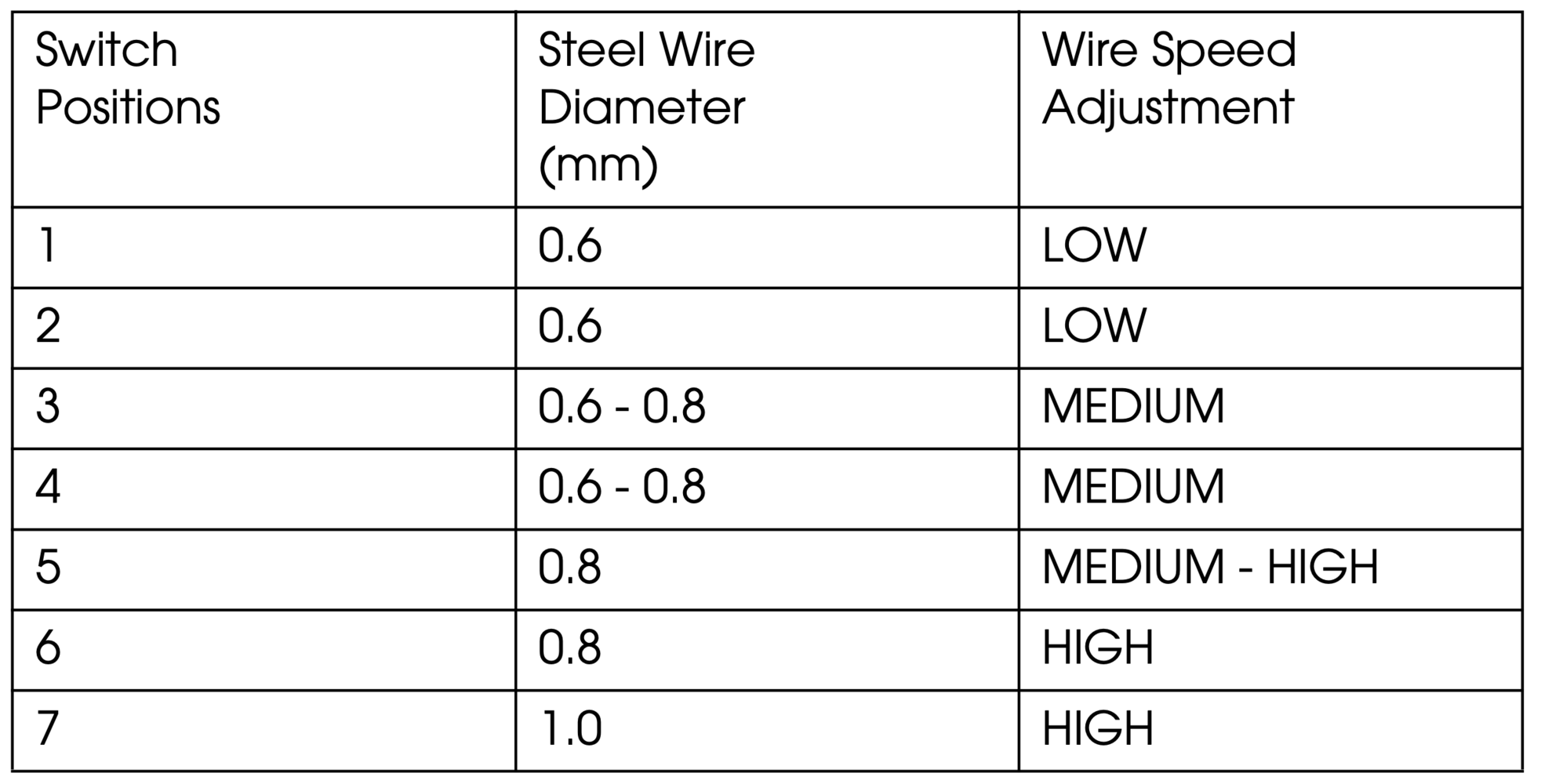

As you can see that one only goes to 0.9 wire. Plus I would have to convert the voltage and speeds on there to be able to use on my Clarke Mig which is 1-7 and 0-10 respectively... whatever that means. Attached is all the Clark manual says

I could collate a table in Excel if I could get enough information together on here.

Thanks in advance all!

Just wondering if anyone has a sort of cheat sheet to get me in the ballpark for settings on different materials, thicknesses and wire sizes?

E.g. something like this https://www.scribd.com/document/407610601/242-MIG-Settings-Chart#

Ideally in metric, up to at least 250a and 1.2mm wire for mild steel with mixed gas.

As you can see that one only goes to 0.9 wire. Plus I would have to convert the voltage and speeds on there to be able to use on my Clarke Mig which is 1-7 and 0-10 respectively... whatever that means. Attached is all the Clark manual says

I could collate a table in Excel if I could get enough information together on here.

Thanks in advance all!

Experience lets you know when it's right.

Experience lets you know when it's right.