drcoastline

New Member

- Messages

- 9

Hi all,

I joined some time ago but have not posted much. I have been reading and trying to learn MIG techniques.

I have a Lincoln 135 Gas welder. It has 4 heat settings A,B,C,D. A being the lowest. It also has infinite speed settings 1-10.

I have set the machine on heat setting B with a wire speed of 3-4 as the graph on the machine more or less states. I have wleded in several patch panels with what I believe are favorable results.

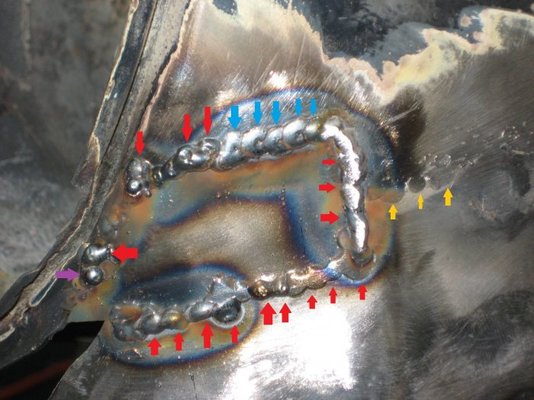

I have been practicing and welding on 20Ga. steel. The photo below is a patch panel on a car fender. The arrows show various welds. The Yellow arrows identify flux core welds I did many years ago. Some of those welds have failed and rusted which is what has prompted the new repairs. The blue arrows identify what I think are good welds with a nice even pool and good penetration. I did a few repairs prior to this piece and the welds looked very similar to those identified by the blue arrows.

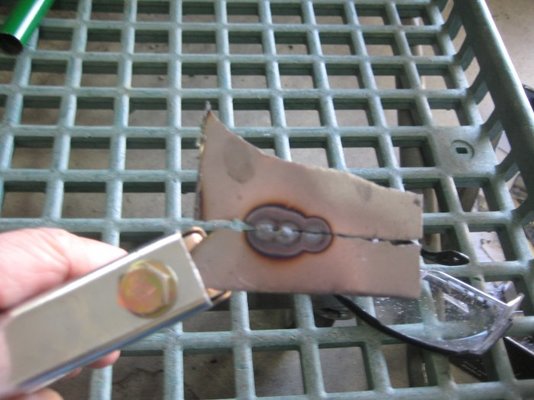

I began this piece with a few quick tacks and then began at the blue arrows. After making the 5 wleds I moved to the lower right. Suddenly the welds seemd to be sitting on top with a slight pop and spatter. It seemed as though the wire wasnt feeding fast enough and the weld was cooling before it could penetrate. The welds identified by the red arrows do not penetrate and the line between the two pieces is clealry visible on the back side. I checked my hose for kinks and tried again. Same thing. I increased my wire speed slightly no better. If you look to the right side of the weld you can see I used a flapper disk to start to knock those welds down.

I then checked my gas flow. 150lbs. in the tank 20lb. @ the tip. Still no better.

I shut the welder down and turned the tank off. I cleaned the tip and checked the wire feed. After about 30 minutes I turned the tank back on ensured gas flow at the tip made sure the wire was moving through freely. I tried again. The weld was still sitting on top, the weld was popping and spattering. Top left and bottom left welds.

I switched to a scrap piece of steel and turned the heat to D I could not get the weld to burn through the scrap.

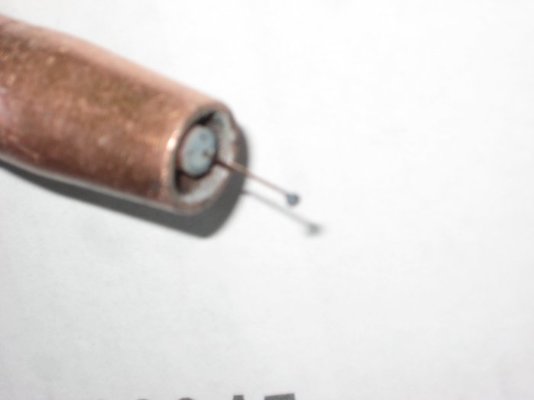

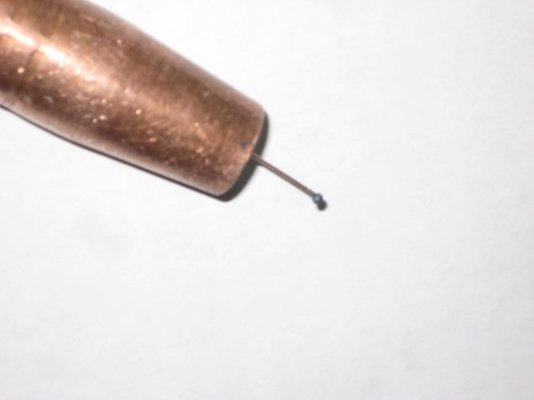

The purple arrow identifies my last attempt for the day. I put the welder back to the original settings and tried again. Now it is making a sizzling sound and the molten wire is pooling up into a bead on the end of the wire.

Are there any suggestions as to what is happening?

Thanks you in advance.

DRC

I joined some time ago but have not posted much. I have been reading and trying to learn MIG techniques.

I have a Lincoln 135 Gas welder. It has 4 heat settings A,B,C,D. A being the lowest. It also has infinite speed settings 1-10.

I have set the machine on heat setting B with a wire speed of 3-4 as the graph on the machine more or less states. I have wleded in several patch panels with what I believe are favorable results.

I have been practicing and welding on 20Ga. steel. The photo below is a patch panel on a car fender. The arrows show various welds. The Yellow arrows identify flux core welds I did many years ago. Some of those welds have failed and rusted which is what has prompted the new repairs. The blue arrows identify what I think are good welds with a nice even pool and good penetration. I did a few repairs prior to this piece and the welds looked very similar to those identified by the blue arrows.

I began this piece with a few quick tacks and then began at the blue arrows. After making the 5 wleds I moved to the lower right. Suddenly the welds seemd to be sitting on top with a slight pop and spatter. It seemed as though the wire wasnt feeding fast enough and the weld was cooling before it could penetrate. The welds identified by the red arrows do not penetrate and the line between the two pieces is clealry visible on the back side. I checked my hose for kinks and tried again. Same thing. I increased my wire speed slightly no better. If you look to the right side of the weld you can see I used a flapper disk to start to knock those welds down.

I then checked my gas flow. 150lbs. in the tank 20lb. @ the tip. Still no better.

I shut the welder down and turned the tank off. I cleaned the tip and checked the wire feed. After about 30 minutes I turned the tank back on ensured gas flow at the tip made sure the wire was moving through freely. I tried again. The weld was still sitting on top, the weld was popping and spattering. Top left and bottom left welds.

I switched to a scrap piece of steel and turned the heat to D I could not get the weld to burn through the scrap.

The purple arrow identifies my last attempt for the day. I put the welder back to the original settings and tried again. Now it is making a sizzling sound and the molten wire is pooling up into a bead on the end of the wire.

Are there any suggestions as to what is happening?

Thanks you in advance.

DRC