Folks I want to have a 316 ss pipe joined to another with as strong a join as I can get. I have access to a very experienced TIG welder but want to ask.

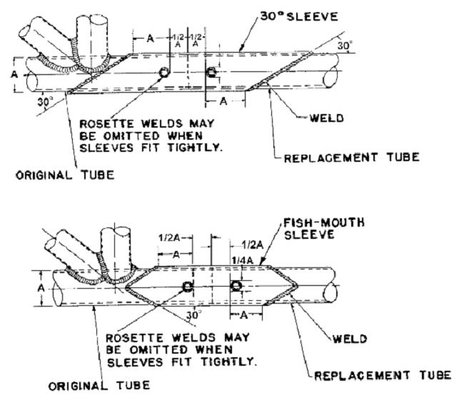

I want to socket the lower tube so that the upper tube fits inside for a few inches. The resultant joint is then to be welded, closing the joint which will then be polished.

What is the best way to produce a socket in the SS tube? one tube is 38.1 OD (male paart) the other (female part) will probably be 42.164mm OD x2.77mm Wall. This gives an ID of 36.624mm. or swap the male - female config so that the male fits inside the 38.1 tube with a flare to suit sizes available?

Any ideas or suggestions welcome. George

I want to socket the lower tube so that the upper tube fits inside for a few inches. The resultant joint is then to be welded, closing the joint which will then be polished.

What is the best way to produce a socket in the SS tube? one tube is 38.1 OD (male paart) the other (female part) will probably be 42.164mm OD x2.77mm Wall. This gives an ID of 36.624mm. or swap the male - female config so that the male fits inside the 38.1 tube with a flare to suit sizes available?

Any ideas or suggestions welcome. George