Hi all

Well I am bike building again after a 3 year break so the welding is dire !

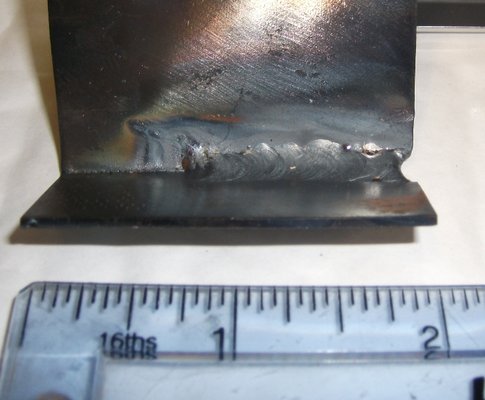

I am having some trouble welding a inside 90' corner on some 1.5" x 1.5" sq tubing 1/16th thickness [ 36mm x 36mm x 1.5mm ]

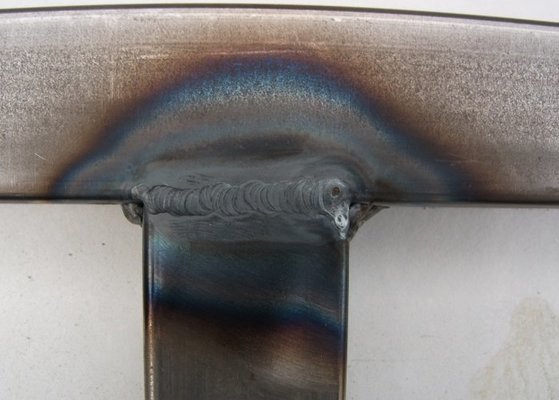

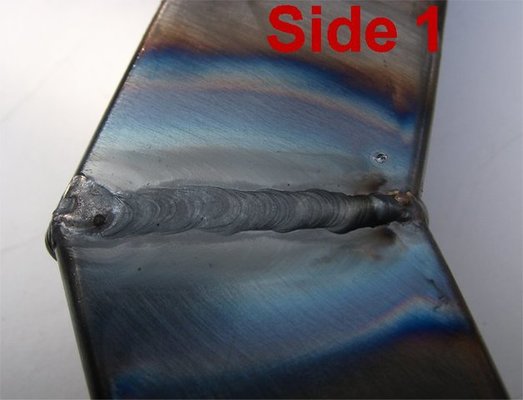

I am happy with one of the flat plate sides and the other is a little lumpy but I will just skim off the high spots.

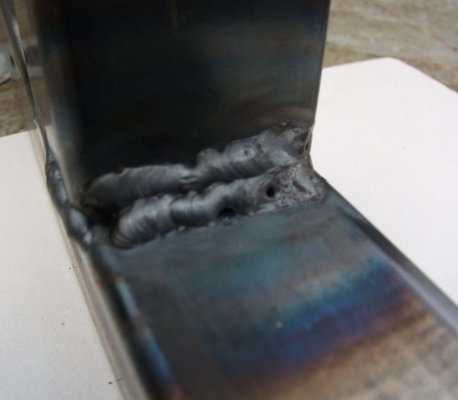

However I am having problems with the inside angles , I think I need the Tungsten out more and maybe 10-15 more amps ?

I did the inside corners first as there were clamps/steel over the flat joints using a 3mm Tungsten.

I can't tell the amps used but did use the same setting for all 4 joints , it is a DC inverter from RTech.

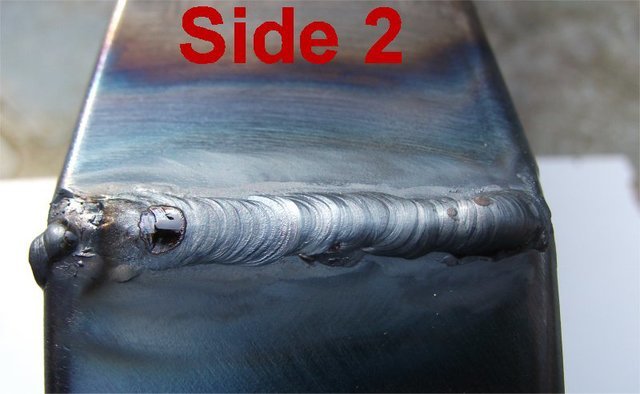

The first weld is the last picture [ shame it is out of focus ] and I may have turned it up a little to do the second inside corner , I had a great deal of difficulty getting a weld pool I could see.

Any criticism that will improve any of the welds is welcome , but please no comments about ms tubing is not suitable for bicycles etc.

regards Paul

Well I am bike building again after a 3 year break so the welding is dire !

I am having some trouble welding a inside 90' corner on some 1.5" x 1.5" sq tubing 1/16th thickness [ 36mm x 36mm x 1.5mm ]

I am happy with one of the flat plate sides and the other is a little lumpy but I will just skim off the high spots.

However I am having problems with the inside angles , I think I need the Tungsten out more and maybe 10-15 more amps ?

I did the inside corners first as there were clamps/steel over the flat joints using a 3mm Tungsten.

I can't tell the amps used but did use the same setting for all 4 joints , it is a DC inverter from RTech.

The first weld is the last picture [ shame it is out of focus ] and I may have turned it up a little to do the second inside corner , I had a great deal of difficulty getting a weld pool I could see.

Any criticism that will improve any of the welds is welcome , but please no comments about ms tubing is not suitable for bicycles etc.

regards Paul