Hello, I’m about to embark on welding up a stainless steel exhaust system (304) for the first time and have a few concerns I would like your thoughts on.

I’ve opted to do down the Solar Flux route. I've bought this stuff. I’ve done this because I weld very slowly. I know this isn't ideal for SS, but will compensate with shorter stitches.

And it's not just the actual welding, but as I’m still quite new to this I spend a lot of time thinking rather than doing. It’s a hobby after all.

This means I would use a hell of a lot of gas back purging.

So my concerns are:

Butt Joints

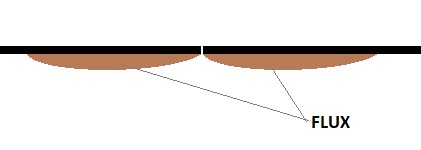

Where I have a but joint, because I will have to apply the flux before tacking the pipe, will I not still have a gap where the weld is? Will it still work as intended? Or does the flux flow when heated to fill any gaps?

Lap Joints

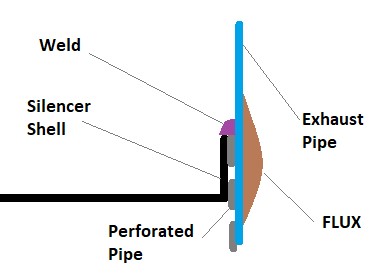

When welding pipe to the silencer it’s effectively a lap joint with a perforated pipe sandwiched between the silencer skin and the pipe. I have no way of protecting this perforate pipe from oxidising. Is this just deemed acceptable?

Finally adding hangers.

This guy and video are excellent. They used solar flux and didn’t worry about any of the above so I’m probably over thinking it.

Towards the end of the video he adds the hangers to the silencers. There is no way of using solar flux inside the silencer. How is this ok?

Greatful for any thoughts.

Thanks

I’ve opted to do down the Solar Flux route. I've bought this stuff. I’ve done this because I weld very slowly. I know this isn't ideal for SS, but will compensate with shorter stitches.

And it's not just the actual welding, but as I’m still quite new to this I spend a lot of time thinking rather than doing. It’s a hobby after all.

This means I would use a hell of a lot of gas back purging.

So my concerns are:

Butt Joints

Where I have a but joint, because I will have to apply the flux before tacking the pipe, will I not still have a gap where the weld is? Will it still work as intended? Or does the flux flow when heated to fill any gaps?

Lap Joints

When welding pipe to the silencer it’s effectively a lap joint with a perforated pipe sandwiched between the silencer skin and the pipe. I have no way of protecting this perforate pipe from oxidising. Is this just deemed acceptable?

Finally adding hangers.

This guy and video are excellent. They used solar flux and didn’t worry about any of the above so I’m probably over thinking it.

Towards the end of the video he adds the hangers to the silencers. There is no way of using solar flux inside the silencer. How is this ok?

Greatful for any thoughts.

Thanks