You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Welding table lock bolt

- Thread starter BelgiqueB

- Start date

Fazerruss

Member

- Messages

- 3,103

I'm guessing the balls are pushed out when the knurled nut is tightened?

Do you have a lathe?

Alternatively you could use those fixings for blind holes on steel beams (can't remember the name) that have a pivoted lever that acts as a back stop. Not sure how easy they'll be to fit and remove vertically though.

Do you have a lathe?

Alternatively you could use those fixings for blind holes on steel beams (can't remember the name) that have a pivoted lever that acts as a back stop. Not sure how easy they'll be to fit and remove vertically though.

Agroshield

Member

- Messages

- 5,402

Start with a Rawlbolt: https://www.rawlplug.com/en/product...g-for-use-in-cracked-and-non-cracked-concrete

Throw away the sleeve that expands into the concrete.

https://rwlcdn.azureedge.net/products/0003/19/0105ae077e2196d96ffe0ec2f8b7aca2fa613e4f.svg

Make a sleeve with two holes in it (holes must be smaller than balls. Balls inserted from inside).

Throw away the sleeve that expands into the concrete.

https://rwlcdn.azureedge.net/products/0003/19/0105ae077e2196d96ffe0ec2f8b7aca2fa613e4f.svg

Make a sleeve with two holes in it (holes must be smaller than balls. Balls inserted from inside).

Think the op has only round holes , tab and slot is the laser cut construction method ,, How thick is the top , could you not just use a straight steel pin and let friction take over , or if needed put a smaller diameter on the pin from say 5mm up and then the left over lip would catch like an internal bearing puller idea.Whats wrong with T nuts Drop through slot 1\4 turn Tighten

What you show is pretty but A. expensive B meant for round holes.C don't like dirt\dust

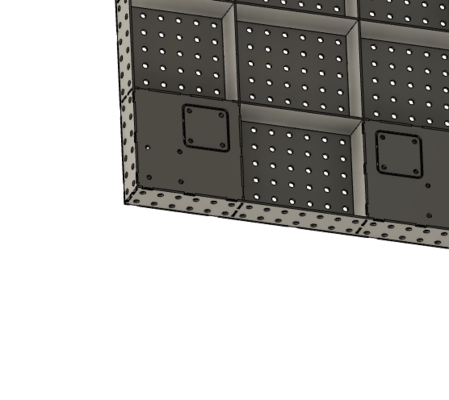

Sorry for the lack of info, it's indeed for a welding table with 16mm round holes, the top plate is 5mm thick. I have a couple of loose plates with the same hole pattern where i want to mount a vice, bench grinder,... stuff like that and be able to put on and off the table quickly and securely when needed. Therefore the 'need' for those bolts, just can't see a doable way to DIY them.

I don't think the rawlbolt idea will work but have some laying around so i'll have a look this weekend.

Might just tap a few holes in the table top for M18 bolts and be done with it.

I don't think the rawlbolt idea will work but have some laying around so i'll have a look this weekend.

Might just tap a few holes in the table top for M18 bolts and be done with it.

mikegolding

Member

- Messages

- 31

Why not tack 16mm nuts on the underside of the holes you want to use. easy to remove if damaged or not needed ?

I just built a plate for my vice with 4 x dogs welded on the bottom to attach to my weld table I threaded the dogs so I can bolt them down under neath if I want to hang off the vice but to be honest with the fit I got the vice is rock solid without being bolted

slim_boy_fat

Forum Supporter

- Messages

- 29,540

- Location

- Scottish Highlands

Sorry for the lack of info, it's indeed for a welding table with 16mm round holes, the top plate is 5mm thick. I have a couple of loose plates with the same hole pattern where i want to mount a vice, bench grinder,... stuff like that and be able to put on and off the table quickly and securely when needed. Therefore the 'need' for those bolts, just can't see a doable way to DIY them.

I don't think the rawlbolt idea will work but have some laying around so i'll have a look this weekend.

Might just tap a few holes in the table top for M18 bolts and be done with it.

View attachment 234697

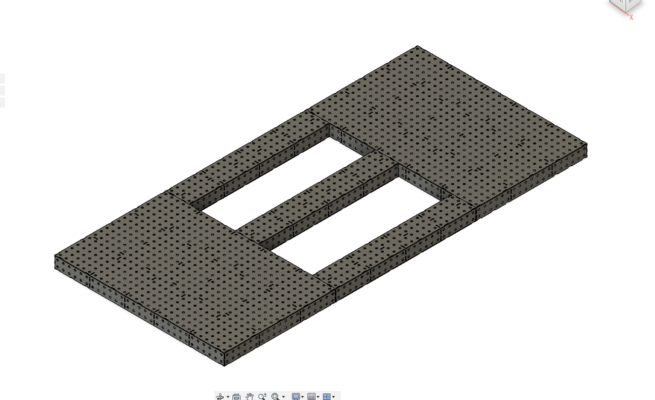

Slightly

fftopic:, but a serious question, why the space in the middle? Unless you're planning something like this in the future...?

fftopic:, but a serious question, why the space in the middle? Unless you're planning something like this in the future...?

Of it's nothing you plan to move daily wouldnt nut and bolt be good enough?

They are not very complicated to fabricate though

View attachment 234725

This old tony on YouTube did a video on ball detents some time ago. Not quite the same they are spring loaded

Thanks for the info, this looks doable on the lathe for a beginner like me :-)!

Slightlyfftopic:, but a serious question, why the space in the middle? Unless you're planning something like this in the future...?

Picture didn't come through :-), I've got a third support beam that i still have to make up to complete the table, went with this design to have it 'modular' time will tell if it's useful though!

How is it held in place, bolts from the bottom?

hotponyshoes

Member

- Messages

- 6,931

- Location

- Somerset. Uk

I can see that big hole in the middle of the table being useful, you could duck under the edge and stand in the middle if you wanted welds on the inside of a frame/were trying to weld up with no distortion/welding something smaller that you could not reach from both sides/so on.

As for the original problem, make a plate as r-d-r has done above with a plate/peg system.

Make 2 diagonal pegs (or all 4) cams so you can lock them in place from the top if you dont have access to the underside.

You could do this by making the bushes as r-d-r has done but with the hole a fraction off center, countersink the underside of the hole and fit a csk bolt from the bottom.

Or don't the other way round, make 2 of the holes in the plate a fraction out of line from the holes in the table, drill them slightly larger than the bolts and countersink them so the bolts will lock the bush in place when you do them up.

If you are feeling fancy get hold of an old mag drill and take the magnet bit off and bolt the vice to that. You could then put it anywhere on the top (or sides) that you wanted.

Even something like a gate latch or fire alarm magnet might well be strong enough to hold a vice for most jobs. If you are bending bars in it you could use pegs to locate it and just use the magnet to hold it down.

As for the original problem, make a plate as r-d-r has done above with a plate/peg system.

Make 2 diagonal pegs (or all 4) cams so you can lock them in place from the top if you dont have access to the underside.

You could do this by making the bushes as r-d-r has done but with the hole a fraction off center, countersink the underside of the hole and fit a csk bolt from the bottom.

Or don't the other way round, make 2 of the holes in the plate a fraction out of line from the holes in the table, drill them slightly larger than the bolts and countersink them so the bolts will lock the bush in place when you do them up.

If you are feeling fancy get hold of an old mag drill and take the magnet bit off and bolt the vice to that. You could then put it anywhere on the top (or sides) that you wanted.

Even something like a gate latch or fire alarm magnet might well be strong enough to hold a vice for most jobs. If you are bending bars in it you could use pegs to locate it and just use the magnet to hold it down.

How is it held in place, bolts from the bottom?

Just by the fit of the dogs in the holes it cant budge when slotted in, you have to lift it exactly vertical off the table. A few of my table holes are a bit dinged now so may well need to thread some holes to allow me screw bolts through to lift it off if its stuck tight. The threaded holes in the middle of the dogs allow me to fasten it down, i have some M10 thumb bolts but as yet haven't had the need.

I have done something slightly different with my bench grinder its mounted on a plate and box section so i can slot it into any of the open ends on my workbenches. The grinder then hangs off the table so you can get long things upto it vertically it works really well.