I went looking for a wood lathe chuck as the large wood lathe I made a few years ago has been designated to continue working as a drum sander (with an attachment I made to fit it) and will continue to do so as I don't have any large trunks to turn on it.

As there are a few smaller jobs that pop up occasionally and it is a bit of a hassle to remove the sander attachment, I started to build a smaller longer wood lathe, have most of the bits and steel laying around in the shed (apart from the chuck) gathering dust.

Dropped by to see a bloke up the coast from me who was selling off a few old wood tools, machines etc., from his shed, and although he didn't have a wood lathe chuck he did have a Dewalt 1251 radial arm saw, so negotiated a price of $50, been after one of these for ages as I wanted to convert one to cut granite and stone with a diamond saw. He did have an old home made wood lathe for sale but it was too "home made" for me.

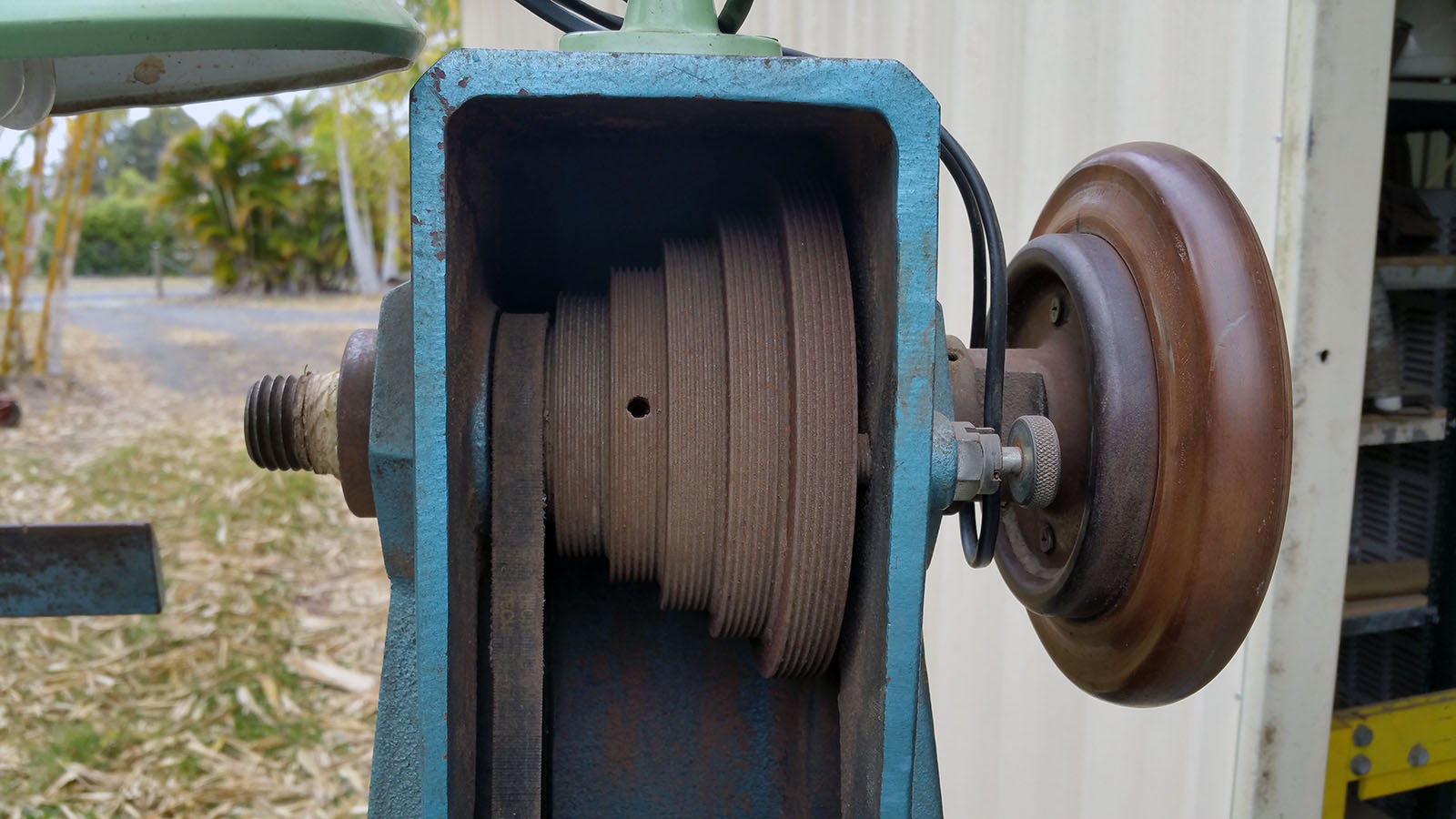

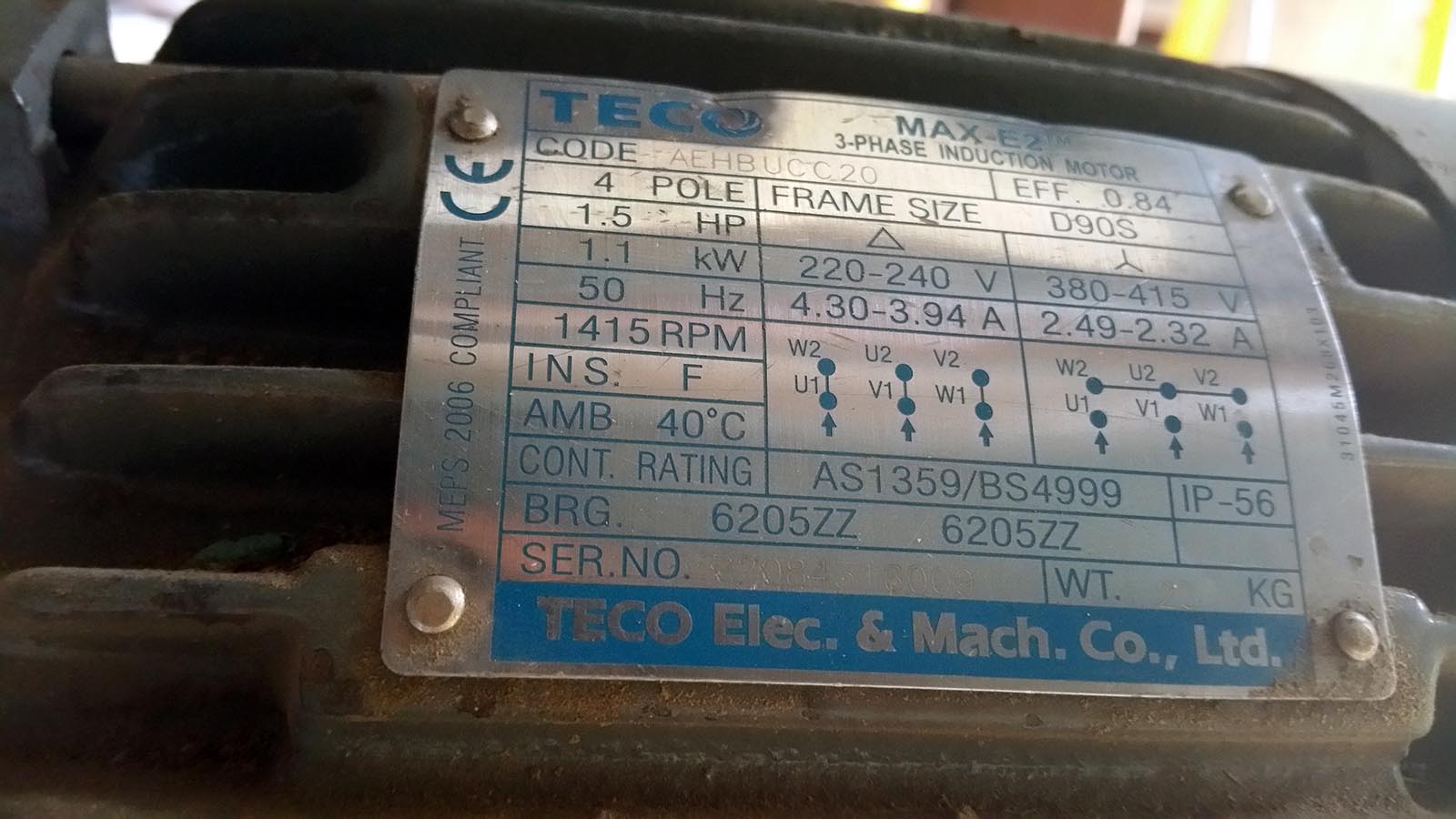

Whilst I was chatting to him he did mention he had a better wood lathe in the other shed which he wasn't using but hadn't even thought about selling. So he showed it to me, turns out it was a 1997 Vicmark VL300. it holds a 1.2m spindle 300mm height off the bed and has a 2006 dual 1 and 3 phase 1.5HP motor on it. The spindle thread is 30mm x 3.5mm so any tooling bits that I get for it will directly fit on to the big wood lathe. Made him

an offer of $250 which he accepted and so that also followed me home.

Saves me time making a lathe from scratch, although I may make another one eventually and sell it off to help pay for some of the tools and bits that I will buy for this one. Overall I think I got a good deal on these two machines even though I still have to get a lathe chuck for it.

As there are a few smaller jobs that pop up occasionally and it is a bit of a hassle to remove the sander attachment, I started to build a smaller longer wood lathe, have most of the bits and steel laying around in the shed (apart from the chuck) gathering dust.

Dropped by to see a bloke up the coast from me who was selling off a few old wood tools, machines etc., from his shed, and although he didn't have a wood lathe chuck he did have a Dewalt 1251 radial arm saw, so negotiated a price of $50, been after one of these for ages as I wanted to convert one to cut granite and stone with a diamond saw. He did have an old home made wood lathe for sale but it was too "home made" for me.

Whilst I was chatting to him he did mention he had a better wood lathe in the other shed which he wasn't using but hadn't even thought about selling. So he showed it to me, turns out it was a 1997 Vicmark VL300. it holds a 1.2m spindle 300mm height off the bed and has a 2006 dual 1 and 3 phase 1.5HP motor on it. The spindle thread is 30mm x 3.5mm so any tooling bits that I get for it will directly fit on to the big wood lathe. Made him

an offer of $250 which he accepted and so that also followed me home.

Saves me time making a lathe from scratch, although I may make another one eventually and sell it off to help pay for some of the tools and bits that I will buy for this one. Overall I think I got a good deal on these two machines even though I still have to get a lathe chuck for it.

]?

]?