olek

Member

- Messages

- 293

- Location

- Paris, France

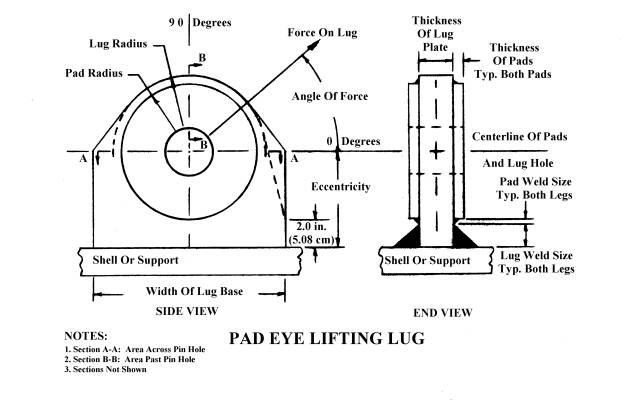

This whole idea of setting the eye into the plate and welding from the back is a disaster.

The whole point is to have reinforced weld metal around the eye to give it strength. A fillet weld is exactly the way to do this for absolute optimum strength.

It’s a proved, tried and tested design and not one we want to be changing over a diy forum. I’ve seen these eyes made exactly as the op is showing lifting 100’s of tonnes such as windtower sections, huge beams for bridges, under ground tanks etc and it’s always a multi pass fillet weld. Although these are designed for a straight up lift you have to assume some side ways forces are going to be applied and there for the reinforcement from a fillet weld design is essential.

Are there bolts passing from underside in the hook part? Would they add some resistance?