Cris B

Every day welding is a school day

- Messages

- 506

- Location

- Sefton

I thought it only fair to back date this post in case anyone else was interested in the work done. All the following coped from another forum:

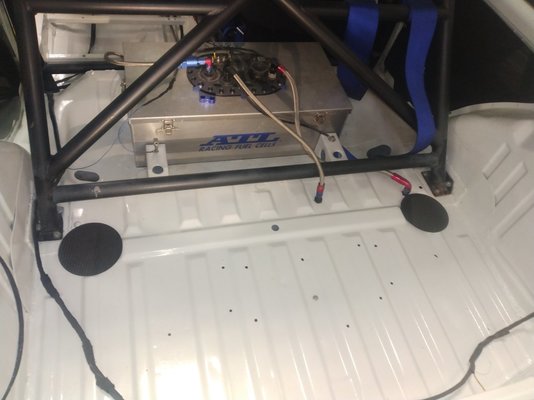

After load of measurements, I fabricated up these supports for the fuel cell container.

Capped off the ends to give a nicer finish - you'll never see it, but it's all about satisfaction about knowing it's been nicely done.

Welded in the supports. Needs a bit of cleaning, but they're solidly mounted now.

A little bit of tidying up to make things symmetrical. The section chopped out to make way for the fuel cell was cannabalised to provide the patch piece. Most difficult thing was getting the measurements right!

Decided the fuel cell needed a better mounting solution so decided to frame the hole in the shell. Very snug fit now with about a 1mm gap around it - Need to fabricate a pair of retaining straps and mount fixings for these at some point.

This is partly to make the mounting more secure under lateral loads and to offer better fitment for the cell container and also to stiffen up the flimsy SWG20 panels. The advice I had received from some one who works building race cars was that the alloy container could be drilled and bolted to the chassis.

This contradicts the fitment guidance specified on the ATL documentation which states you should not do this as the bolts inside the container could chafe the cell and lead to damage, possibly puncturing it. It also strikes me that there is something perverse about drilling holes in what will be a sealed alloy box.

Decided to plate and fill some more holes - there are a good number to fill in the floor plan and on the bulkhead behind the seats too.

Saved some more weight removing unnecessary and rotting bits of metal

After load of measurements, I fabricated up these supports for the fuel cell container.

Capped off the ends to give a nicer finish - you'll never see it, but it's all about satisfaction about knowing it's been nicely done.

Welded in the supports. Needs a bit of cleaning, but they're solidly mounted now.

A little bit of tidying up to make things symmetrical. The section chopped out to make way for the fuel cell was cannabalised to provide the patch piece. Most difficult thing was getting the measurements right!

Decided the fuel cell needed a better mounting solution so decided to frame the hole in the shell. Very snug fit now with about a 1mm gap around it - Need to fabricate a pair of retaining straps and mount fixings for these at some point.

This is partly to make the mounting more secure under lateral loads and to offer better fitment for the cell container and also to stiffen up the flimsy SWG20 panels. The advice I had received from some one who works building race cars was that the alloy container could be drilled and bolted to the chassis.

This contradicts the fitment guidance specified on the ATL documentation which states you should not do this as the bolts inside the container could chafe the cell and lead to damage, possibly puncturing it. It also strikes me that there is something perverse about drilling holes in what will be a sealed alloy box.

Decided to plate and fill some more holes - there are a good number to fill in the floor plan and on the bulkhead behind the seats too.

Saved some more weight removing unnecessary and rotting bits of metal