arther dailey

Member

- Messages

- 6,949

- Location

- England

good job !!

The plate says uF R 45 which translates to 45 uF run capacitor

Its all down to starting torque/work load required wether it permanent capacitor or not,dependant on machine its designed to run, cap start with o/c switch is generally up to 3/4 hp, mostly after that the larger ones have to be permanant cap so start winding stays in to give it the extra power when running,you will find also some fitted with twin capacitors,varying value,one to start and other switches in on run mode.as with welders there is only so much power you can sqeeze out of single phase.I find it depends on age - I've a few 'recent' motors that have a single cap always in circuit and a few older ones that have a single cap and a centrifugal switch.

Extrapolated from the large sample of single phase single cap motors in my shed, I'm going to say it's 50/50

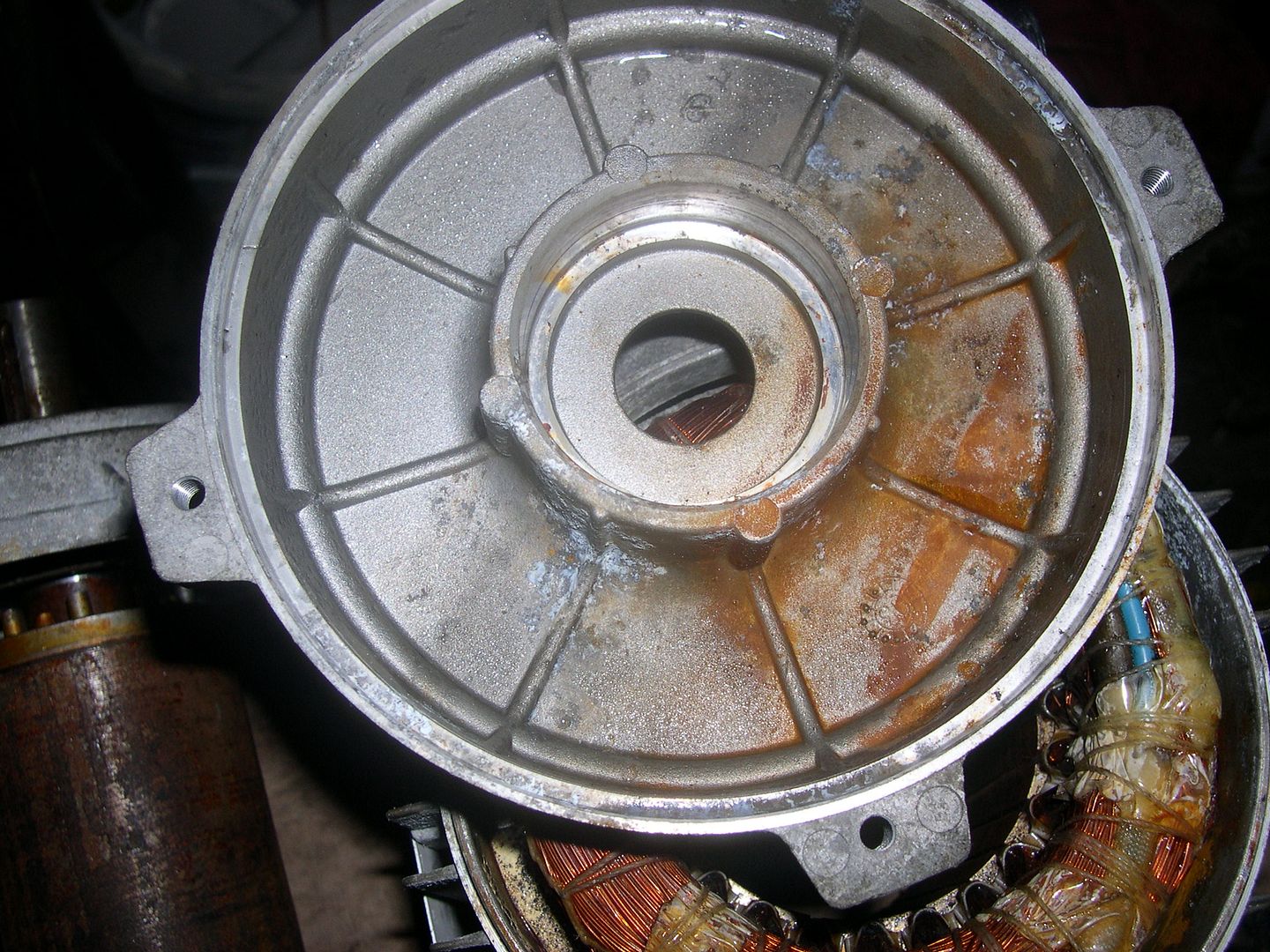

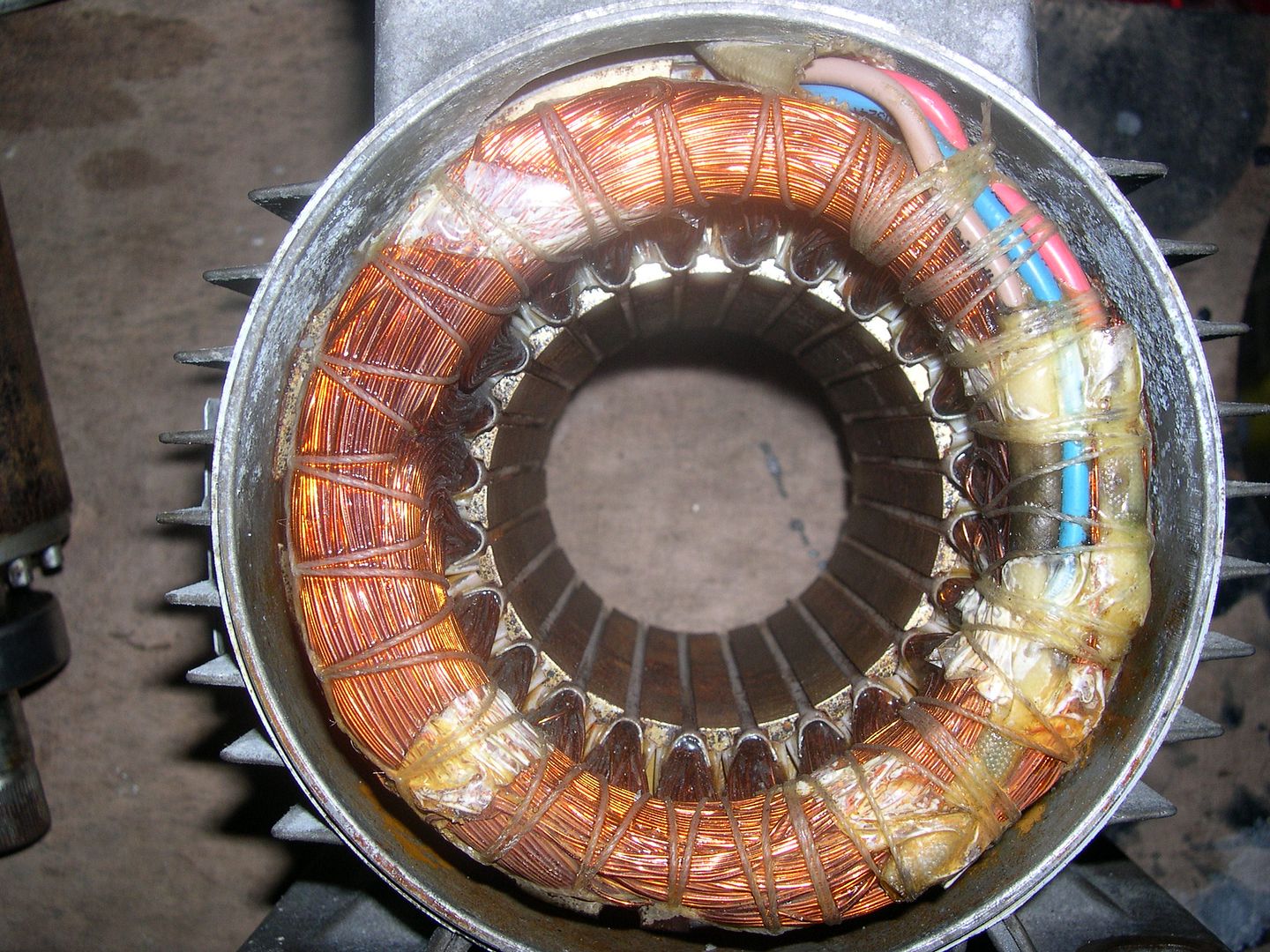

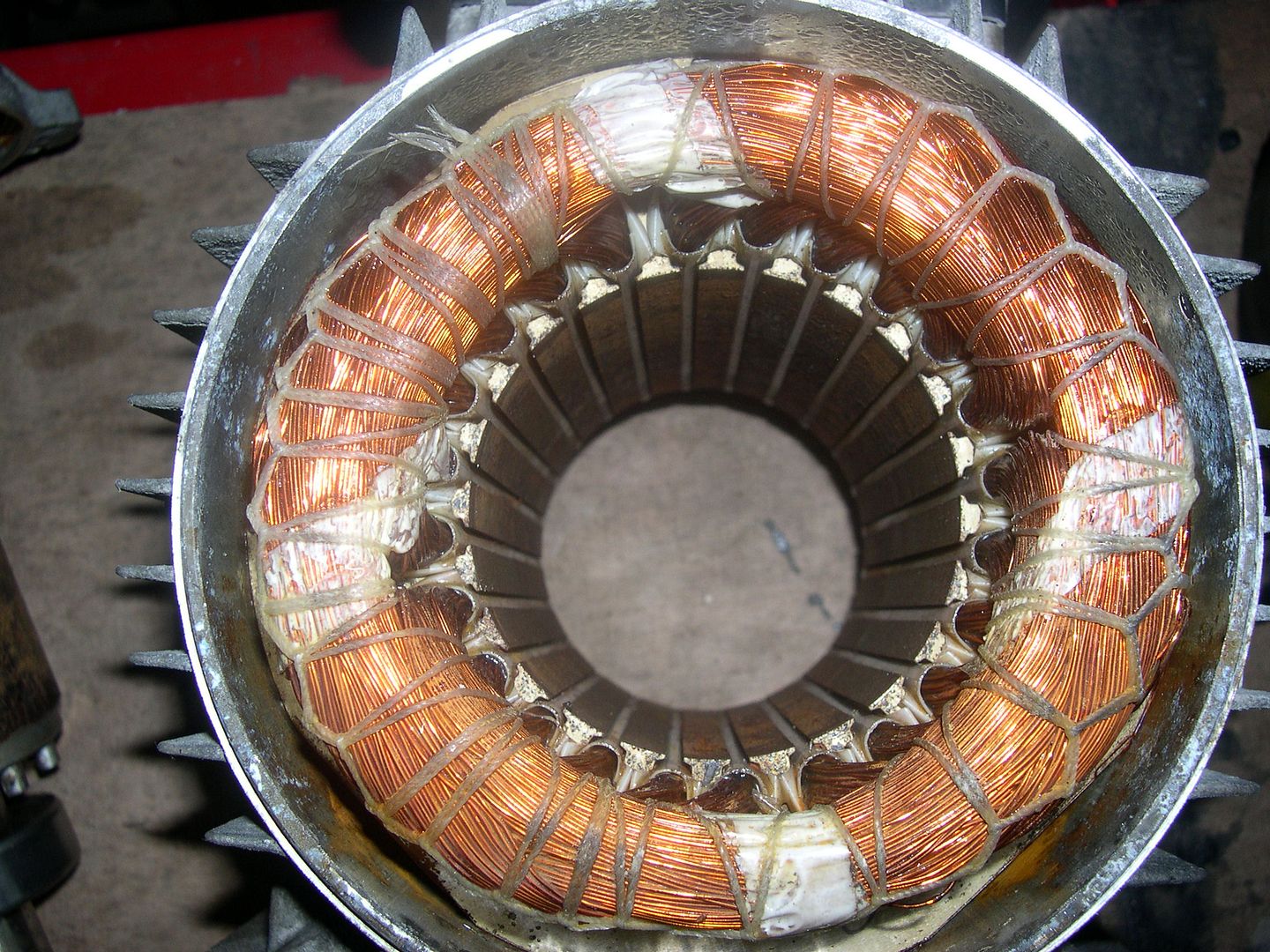

arther is right, I never dipped windings so mistook what could be dry lacquer or whatever they use for solder, seen plenty of solder though laying in the back of over heated burned out generators.Well I only rewound motors every week for 18 years what would I know ! one of the larger ones being the turbo alternator on HMS Hermes!! the windings look good,but may be internal shorts or shorts to earth, the slight glistening you can see is the resin where dipped.you wont see any solder as joints are brazed or silver soldered.

yes the rotor is solid but watch the sweat come out of it as you warm it up,and strangley water and electrics dont seem compatable, anyways I think I will step out of this because to many cooks spoil the broth . good luck ,hope it works out for you. I will keep my fingers crossed. Arther