98_Martin

Member

- Messages

- 46

- Location

- Inverness, UK

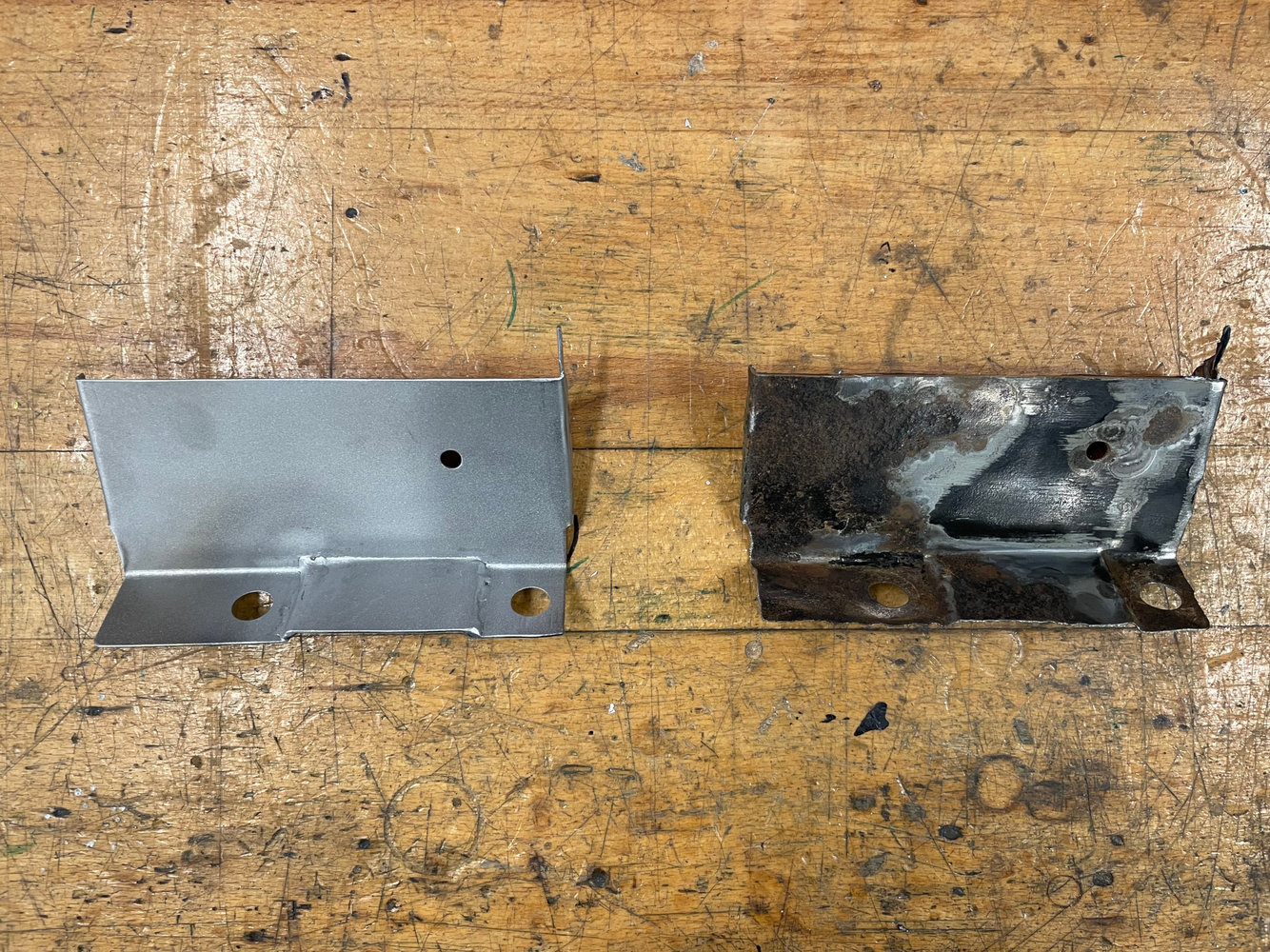

Had a section to repair at the bottom of the front wing, no surprise as it butts up quite tight to the sill and traps moisture and dirt in the gap. When I first took the wing off I put it to the side and thought that a wire wheel and some rust converter would do the job but it was too pitted and the rust would come back in a months time so took the decision to cut the lower part off.

Fabricating the replacement piece wasn't to tricky as it's mainly just 90 degree bends and measuring out the hole centres.

Some body colour painting will be required but the rattle can won't arrive for a week so may delay the car going back on the road unless I live with it in primer for a few weeks until it's through it's MOT which is most likely the way it will go. It isn't terribly visible as most of it lives below the plastic sill cover but a corner will be evident. As for the mounts I am yet to drill I am thinking of going down the route of using rivnuts in place of the original welded captive nuts on the back of the sill for simplicity's sake.

Fabricating the replacement piece wasn't to tricky as it's mainly just 90 degree bends and measuring out the hole centres.

Some body colour painting will be required but the rattle can won't arrive for a week so may delay the car going back on the road unless I live with it in primer for a few weeks until it's through it's MOT which is most likely the way it will go. It isn't terribly visible as most of it lives below the plastic sill cover but a corner will be evident. As for the mounts I am yet to drill I am thinking of going down the route of using rivnuts in place of the original welded captive nuts on the back of the sill for simplicity's sake.

. Looks like fantastic work and effort to me. I wish I had your dedication and indeed talent.

. Looks like fantastic work and effort to me. I wish I had your dedication and indeed talent. .

. )

)