You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Atlas Copco Compressor problem – please help guys

- Thread starter Manchecd

- Start date

brightspark

Member

- Messages

- 41,574

- Location

- yarm stockton on tees

u can make a cheap sh /././.t one of ebay fit for about 12 quid there ok but not as good as the danfoss ones

rtbcomp

Moderator

- Messages

- 18,573

- Location

- Sheffield UK

It depends on the internal layout of the valve

http://www.easupplies.com/CONDOR-USA-INC-AEV1Wi-Unloader-Valve-p/el4bej.htm

Cost nearly as much as a new switch!

http://www.easupplies.com/CONDOR-USA-INC-AEV1Wi-Unloader-Valve-p/el4bej.htm

Cost nearly as much as a new switch!

Hi rtbcomp

I have given your suggestion a try and it emits air but does not close.

If I push the plunger/pin down, it shuts off the air but as soon as I release pressure the air starts to flow again.

At the same time, I loosened the nut on the air-finned pipe where it connects to the NRV (at the imput end) and could hear some air hissing continuously. I left the nut loose, air continued to come out and it emptied the 20 psi or so of air that was in tank.

If I understand correctly how the system works, there should not be any air coming from here. The pump is not running, so it is not pushing air down the pipe towards the tank and the NRV should be stopping air coming back out of the tank.

Am I correct in thinking that this now looks more a NRV problem? If air is coming back out of the tank, the unloader valve will not shut off because there is a continuous stream of air that is preventing it from closing and that is why it contiunues to leak air.

This would also explain the air leaking back into the pump that I can hear.

I would be grateful for your views and anyone else's who has been kind enough to assist on this as to whether I am on the right lines here.

If I am, can the NRV be overhauled? Could there be some grit or dirt that is preventing it from seating properly? Or will I need to get a replacement NRV?

Thanks a lot for your help.

Colin

I have given your suggestion a try and it emits air but does not close.

If I push the plunger/pin down, it shuts off the air but as soon as I release pressure the air starts to flow again.

At the same time, I loosened the nut on the air-finned pipe where it connects to the NRV (at the imput end) and could hear some air hissing continuously. I left the nut loose, air continued to come out and it emptied the 20 psi or so of air that was in tank.

If I understand correctly how the system works, there should not be any air coming from here. The pump is not running, so it is not pushing air down the pipe towards the tank and the NRV should be stopping air coming back out of the tank.

Am I correct in thinking that this now looks more a NRV problem? If air is coming back out of the tank, the unloader valve will not shut off because there is a continuous stream of air that is preventing it from closing and that is why it contiunues to leak air.

This would also explain the air leaking back into the pump that I can hear.

I would be grateful for your views and anyone else's who has been kind enough to assist on this as to whether I am on the right lines here.

If I am, can the NRV be overhauled? Could there be some grit or dirt that is preventing it from seating properly? Or will I need to get a replacement NRV?

Thanks a lot for your help.

Colin

Hi guys

Thanks for your comments.

In the light of my last test, I am wondering whether it is worth examining, overhauling (if this can be done) or replacing the NRV first before going any further with the pressure switch/unloader valve.

Making sure the NRV is working correctly may or may not solve the problem and if it does not then the pressure switch/unloader valve may need sorting as well. But at least we could rule out an NRV problem if we know it is working correctly.

Any thoughts on this?

Colin

Thanks for your comments.

In the light of my last test, I am wondering whether it is worth examining, overhauling (if this can be done) or replacing the NRV first before going any further with the pressure switch/unloader valve.

Making sure the NRV is working correctly may or may not solve the problem and if it does not then the pressure switch/unloader valve may need sorting as well. But at least we could rule out an NRV problem if we know it is working correctly.

Any thoughts on this?

Colin

rtbcomp

Moderator

- Messages

- 18,573

- Location

- Sheffield UK

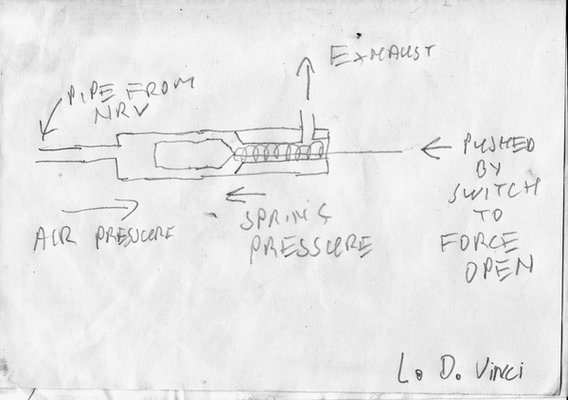

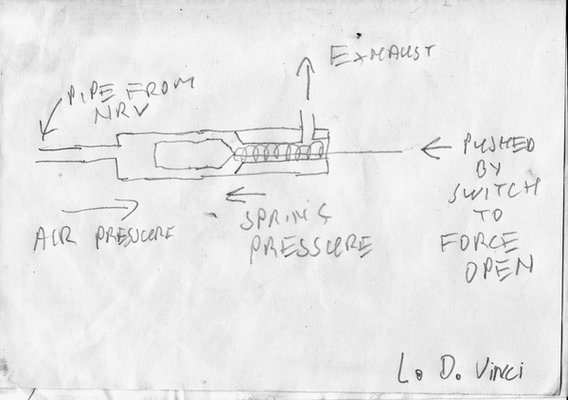

If I push the plunger/pin down, it shuts off the air but as soon as I release pressure the air starts to flow again.

Fair enough, it seems to work opposite way round to what I've seen before.

Am I correct in thinking that this now looks more a NRV problem? If air is coming back out of the tank, the unloader valve will not shut off because there is a continuous stream of air that is preventing it from closing and that is why it contiunues to leak air.

Beginning to look like it, although it normally takes quite a lot of air to shut an unloader valve. Could be your unloader is opened & closed by the switch?

can the NRV be overhauled?

The conventional ones (have a look in my album) can sometimes be fixed by cleaning them, again yours looks a bit different. The rubber plunger in them deteriorates over time.

I am wondering whether it is worth examining, overhauling (if this can be done) or replacing the NRV first before going any further with the pressure switch/unloader valve.

Definitely.

Fair enough, it seems to work opposite way round to what I've seen before.

Am I correct in thinking that this now looks more a NRV problem? If air is coming back out of the tank, the unloader valve will not shut off because there is a continuous stream of air that is preventing it from closing and that is why it contiunues to leak air.

Beginning to look like it, although it normally takes quite a lot of air to shut an unloader valve. Could be your unloader is opened & closed by the switch?

can the NRV be overhauled?

The conventional ones (have a look in my album) can sometimes be fixed by cleaning them, again yours looks a bit different. The rubber plunger in them deteriorates over time.

I am wondering whether it is worth examining, overhauling (if this can be done) or replacing the NRV first before going any further with the pressure switch/unloader valve.

Definitely.

Last edited:

Hi guys

I have now removed and dismantled the NRV valve.

There is certainly a knackered spring in there, possibly knackered or further knackered by me trying a preliminary clean up without completely dismantling.

I have posted up a couple of photos with the parts in their correct order.

The part on the left is for the input pipe from the pump. There is flanged lip at the right hand end and my guess is that the knackered spring seats on this. Just to the left after the flange there is a black rubber sealing washer which you might be able to see and which presumably stops the air coming back out of the tank.

There is then what looks like a brass gear wheel with a spring at the back of it and a collar that seats on the other end of the spring.

I am not really sure how this is supposed to seal as a NRV valve but my guess (and it is only a guess) is this. When the pump is switched off, back pressure from the tank will compress the springs so that the white centre section of the brass gear wheel (I do not know what this is made of but it is not metal and feels 'soft') butts up against the flanged lip of to form an air tight seal so that air cannot flow through the hollow centre of the part on the left of the picture.

The knackered spring looks to be only 2-3 turns of thin wire and, if what I say above is correct, when compressed it will be below the lip of the flange on which it is mounted. If it was not, the flange end would not seal against the white centre section of the brass gear wheel.

The other spring in the picture is one I have found which will mount on the flange and will compress below the lip of the flange.

I have not gone any further at this stage and would be interested to know whether anyone has come across a NRV like this. I have to say it is a bit complicated than I was expecting!!

Thanks a lot for taking the time to read this and I would be grateful for any comments that you might have.

Colin

I have now removed and dismantled the NRV valve.

There is certainly a knackered spring in there, possibly knackered or further knackered by me trying a preliminary clean up without completely dismantling.

I have posted up a couple of photos with the parts in their correct order.

The part on the left is for the input pipe from the pump. There is flanged lip at the right hand end and my guess is that the knackered spring seats on this. Just to the left after the flange there is a black rubber sealing washer which you might be able to see and which presumably stops the air coming back out of the tank.

There is then what looks like a brass gear wheel with a spring at the back of it and a collar that seats on the other end of the spring.

I am not really sure how this is supposed to seal as a NRV valve but my guess (and it is only a guess) is this. When the pump is switched off, back pressure from the tank will compress the springs so that the white centre section of the brass gear wheel (I do not know what this is made of but it is not metal and feels 'soft') butts up against the flanged lip of to form an air tight seal so that air cannot flow through the hollow centre of the part on the left of the picture.

The knackered spring looks to be only 2-3 turns of thin wire and, if what I say above is correct, when compressed it will be below the lip of the flange on which it is mounted. If it was not, the flange end would not seal against the white centre section of the brass gear wheel.

The other spring in the picture is one I have found which will mount on the flange and will compress below the lip of the flange.

I have not gone any further at this stage and would be interested to know whether anyone has come across a NRV like this. I have to say it is a bit complicated than I was expecting!!

Thanks a lot for taking the time to read this and I would be grateful for any comments that you might have.

Colin

rtbcomp

Moderator

- Messages

- 18,573

- Location

- Sheffield UK

Not seen anything like this, but your description makes sense. The spring is very weak, it's the back pressure that keeps the valve closed as you say.

I think the bigger (broken) springs keeps the "gear" in contact with the housing and the other spring keeps the white plunger in the closed position. If the big spring is broken it may allow air to seep past the "gear". Just guessing mind!

I think the bigger (broken) springs keeps the "gear" in contact with the housing and the other spring keeps the white plunger in the closed position. If the big spring is broken it may allow air to seep past the "gear". Just guessing mind!

Hi rtbcomp

Thanks for your thoughts on this.

I will wait to see what other views anyone may have before giving it a try with my weak replacement spring attached to the collar - like you, I think the spring is just a means of mainting contact.

When I refit (probably tomorrow), I will just put a little bit of pressure into the tank to see what happens.

Colin

Thanks for your thoughts on this.

I will wait to see what other views anyone may have before giving it a try with my weak replacement spring attached to the collar - like you, I think the spring is just a means of mainting contact.

When I refit (probably tomorrow), I will just put a little bit of pressure into the tank to see what happens.

Colin

Although this NRV is slightly more elaborate and better engineered than the typical generic NRV now found on many compressors, it follows the same basic operating principal, from what I can see it should function fine. That leaves the pressure switch / unloader valve assembly as the only other possible cause of the fault.

Hi guys

I have encountered a slight problem before I can test the NRV valve.

The brass olive on the output pipe, which forms an airtight seal when the pipe nut is screwed onto the NRV outlet, has come off the pipe.

It looks as though it is an interference fit over the pipe and there is a slight lip inside the olive over which the pipe will need to pass in order for it to be a tight fit.

It does not easily go over this lip and I am reluctant to start using a hammer in case it damages the olive.

Does anyone know whether there is a particular way of fitting these e.g. a special tool, or heating the olive to expand it so that it will go over the pipe more easily?

Any views gratefully received.

Many thanks.

Colin

I have encountered a slight problem before I can test the NRV valve.

The brass olive on the output pipe, which forms an airtight seal when the pipe nut is screwed onto the NRV outlet, has come off the pipe.

It looks as though it is an interference fit over the pipe and there is a slight lip inside the olive over which the pipe will need to pass in order for it to be a tight fit.

It does not easily go over this lip and I am reluctant to start using a hammer in case it damages the olive.

Does anyone know whether there is a particular way of fitting these e.g. a special tool, or heating the olive to expand it so that it will go over the pipe more easily?

Any views gratefully received.

Many thanks.

Colin

Thanks for this.

The only thing that puts me off doing is whether the olive tightens sufficiently on the pipe when the nut is screwed up. It does not look as though it is the type that compresses much, if at all.

If it is not a tight fit on the pipe, the pipe might still move inside the olive even though the but is tightened.

I suppose I could file the lip down a little bit so that it goes easier on the pipe but is still an interference fit.

Colin

The only thing that puts me off doing is whether the olive tightens sufficiently on the pipe when the nut is screwed up. It does not look as though it is the type that compresses much, if at all.

If it is not a tight fit on the pipe, the pipe might still move inside the olive even though the but is tightened.

I suppose I could file the lip down a little bit so that it goes easier on the pipe but is still an interference fit.

Colin

rtbcomp

Moderator

- Messages

- 18,573

- Location

- Sheffield UK

There is a lot of force squeezing a compression olive when you tighten the nut. It will form an interference fit with the pipe over its full depth. It should be a sliding fit when new. A burr will prevent proper tightening. Once an interference fit is obtained you will not be able to move it by hand.

The olive may be loose because it's the wrong size (metric instead of imperial??), the pipe and olive were not clean when assembled or the nut wasn't tight enough.

Any chance of a picture of the olive? if it's a solder type rather than a compression type then obviously it must be soldered in place.

The olive may be loose because it's the wrong size (metric instead of imperial??), the pipe and olive were not clean when assembled or the nut wasn't tight enough.

Any chance of a picture of the olive? if it's a solder type rather than a compression type then obviously it must be soldered in place.

Thanks for your comments.

I have posted up three photos of the olive, one with it slid on the pipe up to the point where it will go no further because of the lip, and two of it on a piece of kitchen towel.

It is a sliding fit over the pipe up to the lip, which is about as sixteenth of inch from the narrower diameter end that slots into the NRV valve.

There is no solder used, pipe and olive and clean, and there are no burrs on the olive or pipe.

The olive in photo 2 should be turned round the other if it was to go on the pipe in photo 1. The dark outer ring of the olive which is set proud is furthest away from the NRV outlet thread. One end of this ring butts up against the inside of the tightening nut on the pipe and the other end butts up against the lip on the external thread on the NRV outlet thread.

Hope this helps.

Colin

I have posted up three photos of the olive, one with it slid on the pipe up to the point where it will go no further because of the lip, and two of it on a piece of kitchen towel.

It is a sliding fit over the pipe up to the lip, which is about as sixteenth of inch from the narrower diameter end that slots into the NRV valve.

There is no solder used, pipe and olive and clean, and there are no burrs on the olive or pipe.

The olive in photo 2 should be turned round the other if it was to go on the pipe in photo 1. The dark outer ring of the olive which is set proud is furthest away from the NRV outlet thread. One end of this ring butts up against the inside of the tightening nut on the pipe and the other end butts up against the lip on the external thread on the NRV outlet thread.

Hope this helps.

Colin

Ah, one of those ! Just tighten it back up ! When initially assembled the olive compresses onto the nipple, that prevents it from moving back if ever removed. If it won't seal after re-tightening the hose will need re-ending, or a new hose if it becomes too short. I know that fitting system and may have the bits on the shelf, depending on size.

It could conceivably be botched to make it seal, using sealing compound, but I didn't say that

It could conceivably be botched to make it seal, using sealing compound, but I didn't say that