Exuptoy

Member

- Messages

- 3,126

- Location

- Maesteg, South Wales

After acquiring my Atlas 10F TV36 and trying to get to grips with it I decided I needed a stand to get it sat at the correct height and so I could reclaim my work bench so I decided to build my own.

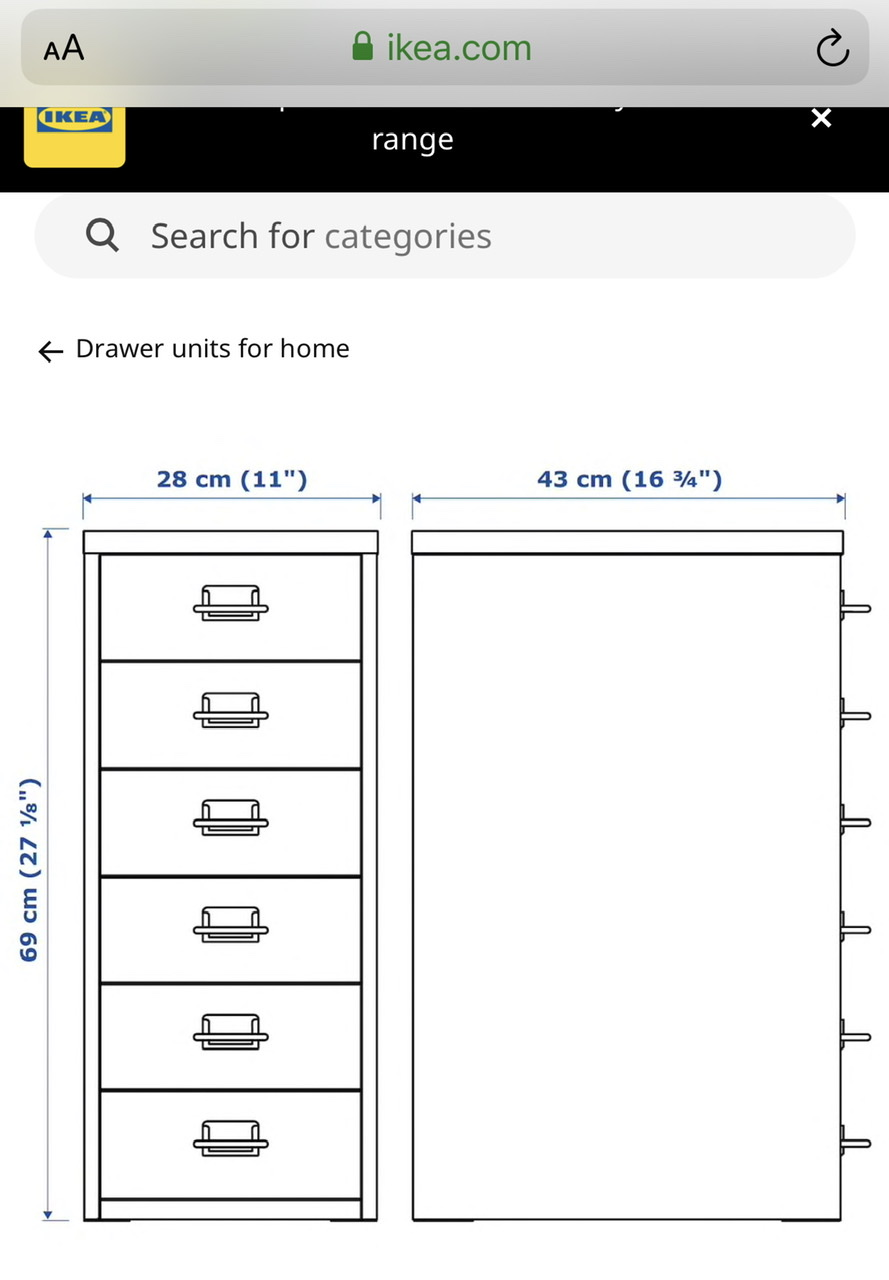

I already had a Bisley style small drawer unit Ikea Helmer for the turning tools etc and purchased a pair of orange Lixhult cabinets for chucks and the like. So a plan was formulating.

I visited my local steel suppliers and purchased a quarter sheet of 5mm steel (600x1250), 4x1200 of 2x1, 8x800 & 8x500 of 1x1 then had a bit of a brain wave that I’d finish off the top with a pair of corners and a 1” fence to retain the swarf as best I can, so went back down to collect another 2x200 & 4x260 of 50x10 to make feet supports which have enough meat to tap for the bed, and some more 2x1 just in case and 1x1/2 at 3.6m of box section to make the fence.

After making the fence I used it to scribe the front corners and cut them off but only after trimming down the top plate to 1100 as 1250 would be too long for the lathe.

I already had a Bisley style small drawer unit Ikea Helmer for the turning tools etc and purchased a pair of orange Lixhult cabinets for chucks and the like. So a plan was formulating.

I visited my local steel suppliers and purchased a quarter sheet of 5mm steel (600x1250), 4x1200 of 2x1, 8x800 & 8x500 of 1x1 then had a bit of a brain wave that I’d finish off the top with a pair of corners and a 1” fence to retain the swarf as best I can, so went back down to collect another 2x200 & 4x260 of 50x10 to make feet supports which have enough meat to tap for the bed, and some more 2x1 just in case and 1x1/2 at 3.6m of box section to make the fence.

After making the fence I used it to scribe the front corners and cut them off but only after trimming down the top plate to 1100 as 1250 would be too long for the lathe.