doubleboost

Member

- Messages

- 3,863

- Location

- Newcastle upon Tyne England

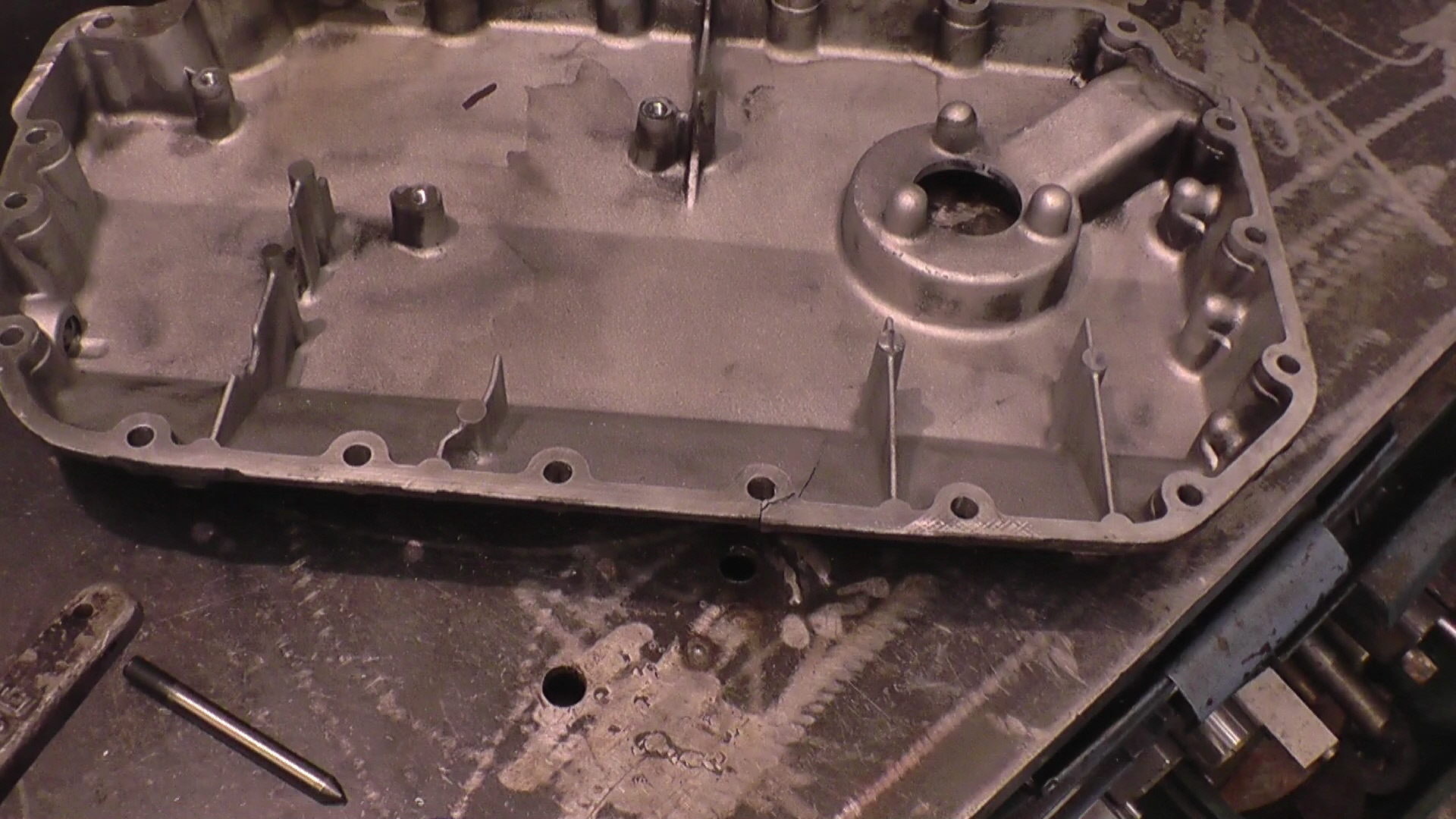

5-minute job that lasted all morning

Bolt hoLe for mounting?Why do you drill it? I’m guessing so you can fill it with weld rather than have a blob on top?

You need a prep and you need to get to the clean Alu. You shouldn’t use abrasives like cutting/grinding as it creates problems with smearing contaminates into the parent. By drilling right through you create a track for a full pen weld and you eliminate that crack altogether.Why do you drill it? I’m guessing so you can fill it with weld rather than have a blob on top?

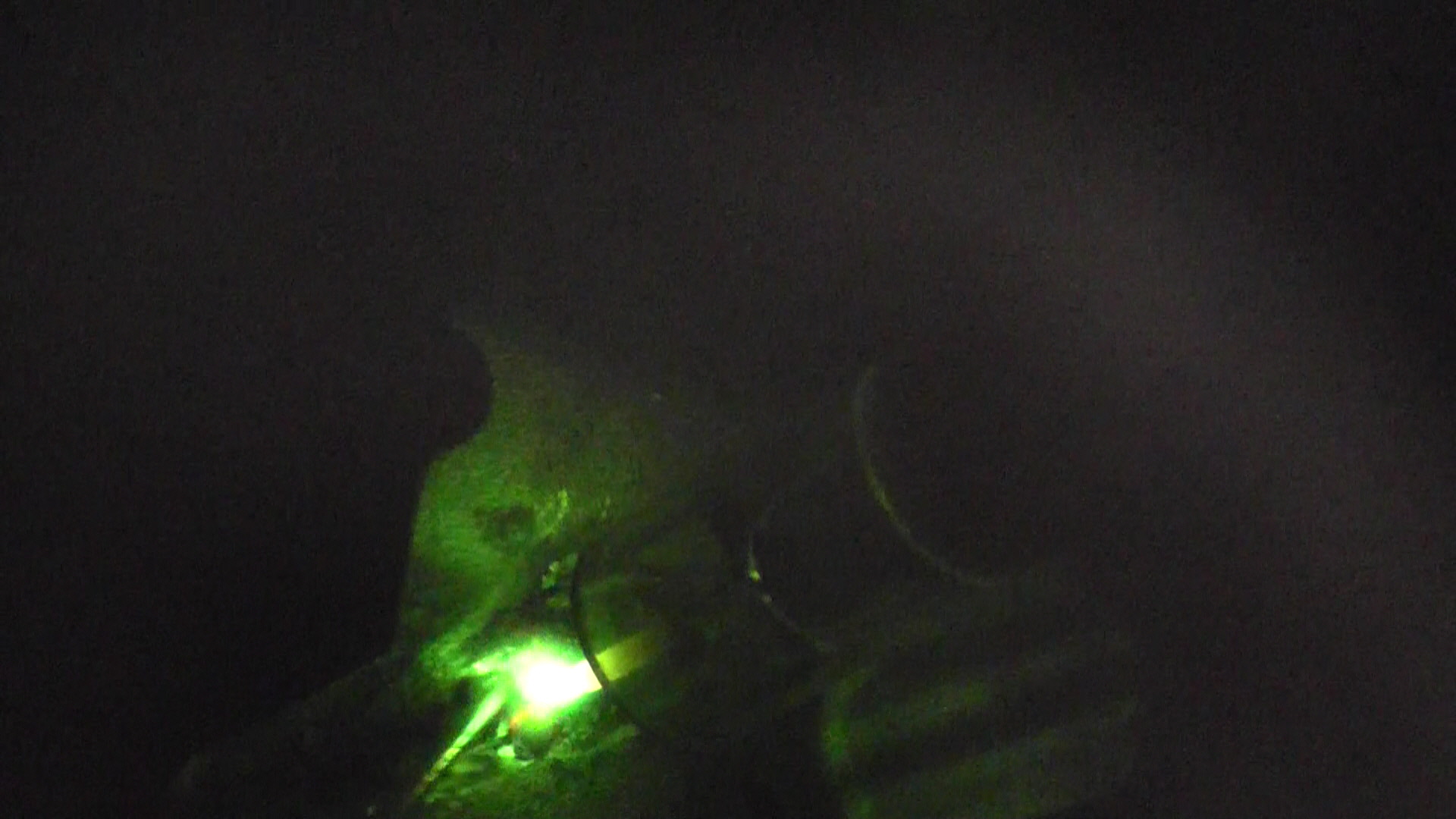

Wonderful job. How did it behave with the welding

Medium grade excrementWonderful job. How did it behave with the welding

Plasma edges weld awfulCould it be done with a plasma cutter rather than a drill? I’m guessing it might leave too rough a finish or be too ragged?

Different yes but far from impossible. I’ve welded hundreds of these things. All different in the way they behave. Some have flowed beautifully some have been a fight from start to finish.literaly impossible to tig it

Alu or steel.on sumps i burn the area with gas, dig the crack out with the grinder and mig weld it, they get 1 chance. they ether weld or get skiped