You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blasting Pot Mods

- Thread starter mylesdw

- Start date

knoba

...break a leg!

- Messages

- 863

- Location

- Sussex, England

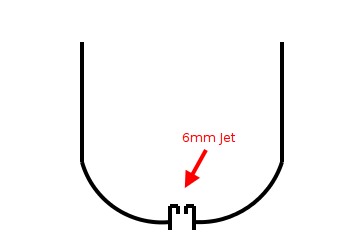

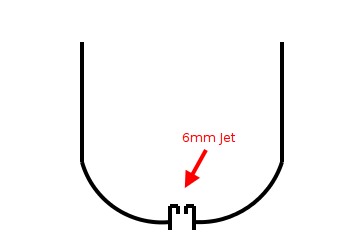

I jetted my outgo to 6mm, and; as long as the abrasive is graded properly & dry I don't have to kick it anymore...

Think: carburetor…

I also opened up the outlet to 3/4" bspt by welding in a 16mm thick disc. I left a 1/8" plus root gap and got a great result with the MIG. I didn't think it would bridge the gap at first but it really pulled through for me.

https://knoba.wordpress.com/2013/10/14/made-a-pressure-pot-sandblaster/

hth

Think: carburetor…

I also opened up the outlet to 3/4" bspt by welding in a 16mm thick disc. I left a 1/8" plus root gap and got a great result with the MIG. I didn't think it would bridge the gap at first but it really pulled through for me.

https://knoba.wordpress.com/2013/10/14/made-a-pressure-pot-sandblaster/

hth

Rig Pig

Member

- Messages

- 3,742

- Location

- Narrwich! U.K.

That's not too bad, I've got 30cfm to play with so it should work, I was half expecting 60cfm +It's a lot. With the smallest nozzle I could buy (1/8") and running it from a 15cfm (approx) single phase compressor I reckon you're lucky to get 50% duty time at 100 psi.

View attachment 63498

brightspark

Member

- Messages

- 40,167

- Location

- yarm stockton on tees

UOTE="Rig Pig, post: 636549, member: 21254"]That's not too bad, I've got 30cfm to play with so it should work, I was half expecting 60cfm +[/QUOTE]a 28cfm will run a 3mm jet easily with some to spare no probs@90psi

brightspark

Member

- Messages

- 40,167

- Location

- yarm stockton on tees

if u ever want to know what pressure your comp will run jets at before u buy them just get a bit of round rod 10 mm cut a bit off and drill diffrent size holes in it. fit in the end of blast hose with a jubily clip and take the pressure readings for each size hole

knoba

...break a leg!

- Messages

- 863

- Location

- Sussex, England

Thanks, mylesdw!Enjoyed your site Knoba, love that blasting cabinet. I have plenty of drums around but never thought of using one for that purpose.

For bigger stuff I use a 6 man tent I got off freecycle, ppe up & get in there with it.

rtbcomp

Moderator

- Messages

- 18,574

- Location

- Sheffield UK

Thanks for the update

There are gate-type grit valves, think normal gate valve with a rubber sleeve for the grit to flow through, the sleeve is squeezed by the piston in the valve. This avoids the flat ledges mentioned above.

A good question and my best guess is that

1. The piston shape means there is no flat area for the sand to collect on

and

2. The cylinder is not at right angles to the incoming sand flow; again no flat 'shelf' for the sand to collect on.

3. The piston is shiny: like a hydraulic ram

We shall see whether it works but I did notice on my last trip to the blasters that he has something VERY similar (although must bigger) on his pot.

There are gate-type grit valves, think normal gate valve with a rubber sleeve for the grit to flow through, the sleeve is squeezed by the piston in the valve. This avoids the flat ledges mentioned above.

brightspark

Member

- Messages

- 40,167

- Location

- yarm stockton on tees

there ok on the larger pots as grit size isnt critical but on smaller units they dont work and can block easilyThanks for the update

There are gate-type grit valves, think normal gate valve with a rubber sleeve for the grit to flow through, the sleeve is squeezed by the piston in the valve. This avoids the flat ledges mentioned above.

brightspark

Member

- Messages

- 40,167

- Location

- yarm stockton on tees

anyone wanting a decent grit valve and cant make there own heres the clone of a clemco minipot for not a lot of money i made mine over 20 years ago heres the link the mini flat sand valve  https://www.centurywise.co.uk/blast-equipment/abrasives-metering-valves-/Small-flat-sand-valve

https://www.centurywise.co.uk/blast-equipment/abrasives-metering-valves-/Small-flat-sand-valve

Coo

Member

- Messages

- 760

anyone wanting a decent grit valve and cant make there own heres the clone of a clemco minipot for not a lot of money i made mine over 20 years ago heres the link the mini flat sand valvehttps://www.centurywise.co.uk/blast-equipment/abrasives-metering-valves-/Small-flat-sand-valve

You could make a few bob knocking them out cheaper !

Hi Brightspark,anyone wanting a decent grit valve and cant make there own heres the clone of a clemco minipot for not a lot of money i made mine over 20 years ago heres the link the mini flat sand valvehttps://www.centurywise.co.uk/blast-equipment/abrasives-metering-valves-/Small-flat-sand-valve

I've been looking at your homemade abrasive valve and wondered if you've any sizes etc to help me with manufacturing one for my pot?

Cheers

Ian

brightspark

Member

- Messages

- 40,167

- Location

- yarm stockton on tees