Hi,

Six months ago Bron bought me the TIG welder with me wanting to weld up a new aluminium petrol tank for the Colt mower I'd just fully restored; what an epic its been and once again I'd like to thank each and every forum member for your kind help and patience.

I was never in any doubt I would succeed but I did wonder if I'd live long enough. The weather here is as usual being dire; yesterday morning it was snow first thing turning to heavy rain which is still coming down and with an high of 5C it's hardly sweltering outside today. Yesterday so fed up of being a prisoner due to the weather I accepted getting wet and wandered into the workshop; with the 2kw fan heater full on blowing at me I finally welded on both domed ends then got wet again when I knocked off but feeling pleased with myself. I've just got wet again having left the workshop where I've welded on the filler neck and tap mounting; I'm unable to weld mounting brackets because the mower is half way up the garden in the hut and I'll now wait until the rain stops before venturing up there.

Because of the mower restoration I can now metal spin and TIG weld aluminium; OK it's taken six months but I've gained two very useful new skills which I wouldn't now have if I'd just moaned about all the problems and given up and a real bonus is being a member of this forum.

Thanks guys.

Kind regards, Colin.

New filler cap and neck bought through eBay. The small item is the petrol tap mounting which I failed to weld; I don't know what kind of aluminium it is but it refused to weld.

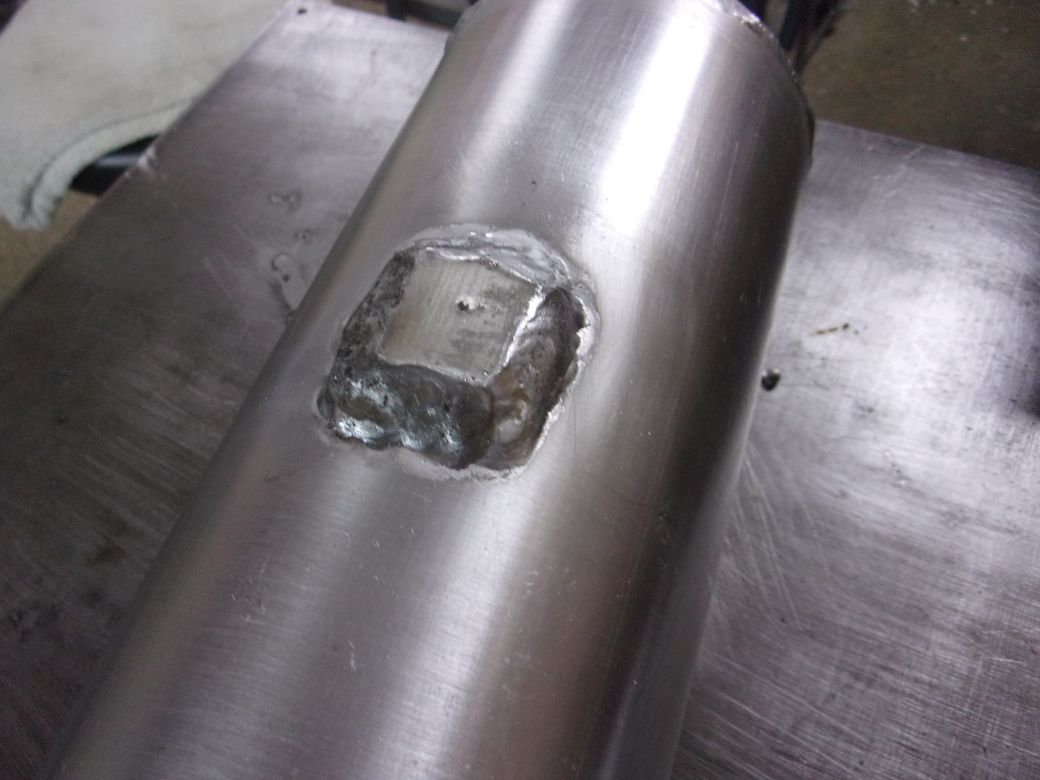

Plan "B" mounting for petrol tap; not pretty but it's welded.

New filler neck fully welded which was fun.

At last the new tank in all its glory; the tank end welds turned out better than expected considering I had the shakes to my hands; perhaps some day Yorkshire will attract some of this global warming; it's struggling to reach 5C today and with lots of heavy rain. Pleasure or punishment in making this tank; I'm unsure which?

Six months ago Bron bought me the TIG welder with me wanting to weld up a new aluminium petrol tank for the Colt mower I'd just fully restored; what an epic its been and once again I'd like to thank each and every forum member for your kind help and patience.

I was never in any doubt I would succeed but I did wonder if I'd live long enough. The weather here is as usual being dire; yesterday morning it was snow first thing turning to heavy rain which is still coming down and with an high of 5C it's hardly sweltering outside today. Yesterday so fed up of being a prisoner due to the weather I accepted getting wet and wandered into the workshop; with the 2kw fan heater full on blowing at me I finally welded on both domed ends then got wet again when I knocked off but feeling pleased with myself. I've just got wet again having left the workshop where I've welded on the filler neck and tap mounting; I'm unable to weld mounting brackets because the mower is half way up the garden in the hut and I'll now wait until the rain stops before venturing up there.

Because of the mower restoration I can now metal spin and TIG weld aluminium; OK it's taken six months but I've gained two very useful new skills which I wouldn't now have if I'd just moaned about all the problems and given up and a real bonus is being a member of this forum.

Thanks guys.

Kind regards, Colin.

New filler cap and neck bought through eBay. The small item is the petrol tap mounting which I failed to weld; I don't know what kind of aluminium it is but it refused to weld.

Plan "B" mounting for petrol tap; not pretty but it's welded.

New filler neck fully welded which was fun.

At last the new tank in all its glory; the tank end welds turned out better than expected considering I had the shakes to my hands; perhaps some day Yorkshire will attract some of this global warming; it's struggling to reach 5C today and with lots of heavy rain. Pleasure or punishment in making this tank; I'm unsure which?

Any pics of the rest of the mower [unless I've missed them in other posts...

Any pics of the rest of the mower [unless I've missed them in other posts... ]

] at least the petrol tap area is on the underside. I wonder if that piece of alloy had Zinc in it...

at least the petrol tap area is on the underside. I wonder if that piece of alloy had Zinc in it...