- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boring out a tractor axle

- Thread starter brewdexta

- Start date

brewdexta

The biggest tool in the box

- Messages

- 5,629

- Location

- UK

Here's the chip out of the pulley, I've moved the belt onto it and given it a go and although there is a little bit of a throbbing noise I think I will get away with it for this job then I'll take the thing apart. Looking at the pulleys they seem sectional so maybe I can get them separated. I'll ask on the Tom Senior forum.

All I need now is me calipers fixing or a bore gauge and I shall boring it out, a bit of a marathon for something that will seem so simple to many I'm looking at the Allendale/Machine-DRO web site and can see the calliper spares, I shall be placing an order today.

I'm looking at the Allendale/Machine-DRO web site and can see the calliper spares, I shall be placing an order today.

Cheers

Andy

All I need now is me calipers fixing or a bore gauge and I shall boring it out, a bit of a marathon for something that will seem so simple to many

I'm looking at the Allendale/Machine-DRO web site and can see the calliper spares, I shall be placing an order today.

I'm looking at the Allendale/Machine-DRO web site and can see the calliper spares, I shall be placing an order today.Cheers

Andy

Bill Edwards

Member

- Messages

- 4,959

- Location

- Scarborough, North Yorkshire

I'd run it happily on that pulley, done worse.

brewdexta

The biggest tool in the box

- Messages

- 5,629

- Location

- UK

Here's it after moving the centre to take out the ovality and about half way through boring, you can see how the pin has pitched about and worn the bore.

Here's the hole just 0.1mm short of the oilite bearing OD to allow for the bearing to be shrunk in liquid nitrogen and dropped in. Unfortunately I haven't quite got rid of the wear, close but no cigar, so I've bought a 2-1/4" OD bearing. I believe oilite is a pig to machine down so probably means boring out the hole another 1/4".

Cheers

Andy

Here's the hole just 0.1mm short of the oilite bearing OD to allow for the bearing to be shrunk in liquid nitrogen and dropped in. Unfortunately I haven't quite got rid of the wear, close but no cigar, so I've bought a 2-1/4" OD bearing. I believe oilite is a pig to machine down so probably means boring out the hole another 1/4".

Cheers

Andy

Wendelspanswick

Member

- Messages

- 6,486

Where do you lay your hands on liquid Nitrogen?

AndyStobbs

Member

- Messages

- 2,475

- Location

- North West England

Nice work, I know how it feels to have to sort out a dozen small but related jobs before you can crack on with the central job.

brewdexta

The biggest tool in the box

- Messages

- 5,629

- Location

- UK

Cheers Andy, I want to get this done then I can take a load down to the blasters so I can get them in primer. I will probably take the wheels, footplates, front axle and stub axles, front axle carrier, rear brake back plates and a host of other stuff in one hit. At the same time I need to drop the block off for liners to be fitted and the crank checked. The clutch should be fun, its a two stage clutch for the PTO.

brewdexta

The biggest tool in the box

- Messages

- 5,629

- Location

- UK

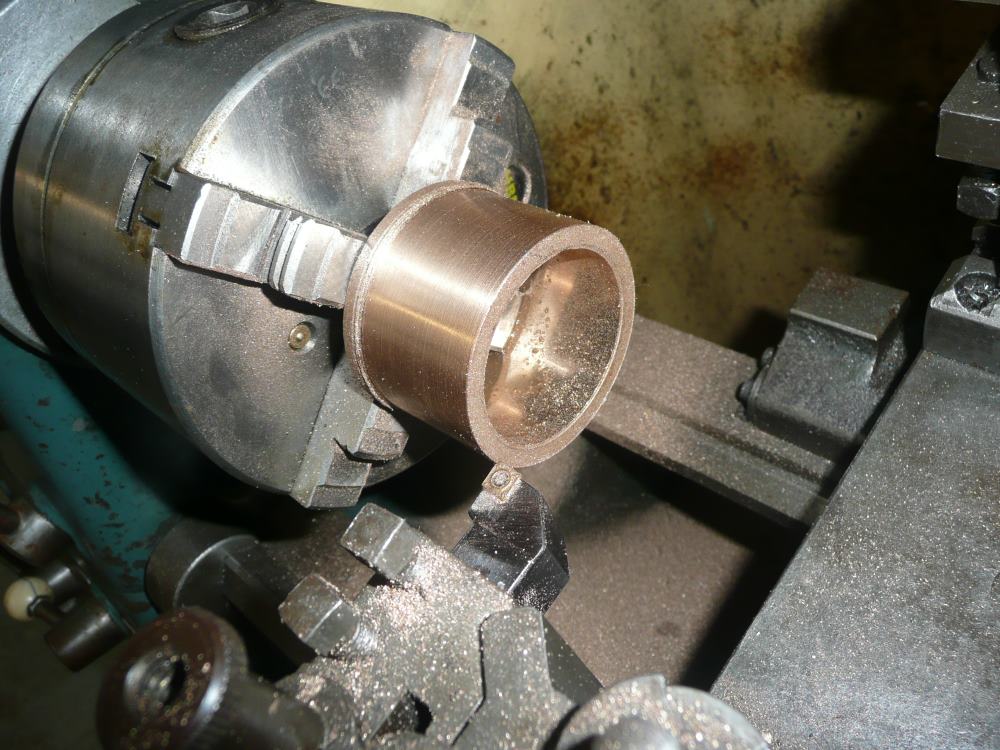

I had to bore the axle out to 52mm ID in the end so the 2" OD bush wasn't big enough so I got a 2 - 1/4" OD oilite bush with the same ID and I'm turning it down to just over 52mm before pressing it in.

The wear has gone

Turning down the oilite bush on my newish 4 jaw self centring chuck. the oilite leaks oil in buckets even though I'm taking it steady and not getting it too hot, I guess I shall have to soak it in oil before use.

Cheers

Andy

The wear has gone

Turning down the oilite bush on my newish 4 jaw self centring chuck. the oilite leaks oil in buckets even though I'm taking it steady and not getting it too hot, I guess I shall have to soak it in oil before use.

Cheers

Andy

AndyStobbs

Member

- Messages

- 2,475

- Location

- North West England

How do you find that boring head for flex? Fair ald unsupported length there isn't there. What size increments where you using?

brewdexta

The biggest tool in the box

- Messages

- 5,629

- Location

- UK

Hi Andy

I was only cutting about 0.15mm at a time, and 0.1mm as I got closer, so 0.3mm or 0.2mm in diameter. Its a Vertex Taiwanese boring head which I have absolutely no fault with, seems excellent quality. The bits are the usual hobbyist chronos/RDG type kit but seems good enough for my purposes so far.

The recent tweak to the lathe has made a huge difference, for the first time I have confidence in its abilities so instead of sending the axle, bush and lump of steel to make the pin to my mates I shall do it myself. It means I won't have the luxury of liquid nitrogen so I need to work out what the bush and axle need to be finished to so I can press them in successfully.

Sticking the bush in the freezer and/or warming the axle up a bit won't do a great deal I don't think however working out this will be a job for the train to work tomorrow

Currently the axle is bored out to gnats below 52mm and the bush OD is 52.2mm.

Cheers

Andy

I was only cutting about 0.15mm at a time, and 0.1mm as I got closer, so 0.3mm or 0.2mm in diameter. Its a Vertex Taiwanese boring head which I have absolutely no fault with, seems excellent quality. The bits are the usual hobbyist chronos/RDG type kit but seems good enough for my purposes so far.

The recent tweak to the lathe has made a huge difference, for the first time I have confidence in its abilities so instead of sending the axle, bush and lump of steel to make the pin to my mates I shall do it myself. It means I won't have the luxury of liquid nitrogen so I need to work out what the bush and axle need to be finished to so I can press them in successfully.

Sticking the bush in the freezer and/or warming the axle up a bit won't do a great deal I don't think however working out this will be a job for the train to work tomorrow

Currently the axle is bored out to gnats below 52mm and the bush OD is 52.2mm.

Cheers

Andy

brightspark

Member

- Messages

- 40,321

- Location

- yarm stockton on tees

u would be supprised how much diffrence putting the bush in the freezer will make and heating the axle ,why dont u make it a slip in fit and loctite it , it wont go anywhere.u can be too criticalHi Andy

I was only cutting about 0.15mm at a time, and 0.1mm as I got closer, so 0.3mm or 0.2mm in diameter. Its a Vertex Taiwanese boring head which I have absolutely no fault with, seems excellent quality. The bits are the usual hobbyist chronos/RDG type kit but seems good enough for my purposes so far.

The recent tweak to the lathe has made a huge difference, for the first time I have confidence in its abilities so instead of sending the axle, bush and lump of steel to make the pin to my mates I shall do it myself. It means I won't have the luxury of liquid nitrogen so I need to work out what the bush and axle need to be finished to so I can press them in successfully.

Sticking the bush in the freezer and/or warming the axle up a bit won't do a great deal I don't think however working out this will be a job for the train to work tomorrow

Currently the axle is bored out to gnats below 52mm and the bush OD is 52.2mm.

Cheers

Andy

Bill Edwards

Member

- Messages

- 4,959

- Location

- Scarborough, North Yorkshire

Agree with brightspark, a little heat and cooling will help.

I'd also be inclined to use loctite, make sure it can't ever turn in the axle. Makes the repair job a little better, and gives a touch more margin for error!

I'd also be inclined to use loctite, make sure it can't ever turn in the axle. Makes the repair job a little better, and gives a touch more margin for error!

brewdexta

The biggest tool in the box

- Messages

- 5,629

- Location

- UK

Thanks guys, I shall take your advice, I measured the bush after sticking it in the freezer and it had shrunk a reasonable amount however my calipers are a bit crap and I don't have a micrometer above 2" to measure it accurately. I was going to buy some decent calipers last week and got sidetracked. I shall dig deep and order some.

Cheers

Andy

Cheers

Andy