You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Burgess Powerline Sprayit (electric compressor)

- Thread starter Des53

- Start date

it's difficult to know which is best, yesterday I visited a chap who does a huge amount of resto work mainly on old motorcycles, he runs

spray paint equipment, air tools, and a sizeable blast cabinet, and he advised me on this twin cylinder direct drive type, saying that he was

disappointed with the belt drive one he had previously. But who knows perhaps there was a fault with it....

spray paint equipment, air tools, and a sizeable blast cabinet, and he advised me on this twin cylinder direct drive type, saying that he was

disappointed with the belt drive one he had previously. But who knows perhaps there was a fault with it....

- Messages

- 22,244

- Location

- Birmingham

Direct drive a noisy, look for a belt drive with iron cylinders.

Wallace

Member

- Messages

- 7,705

- Location

- Staines, Middlesex, England.

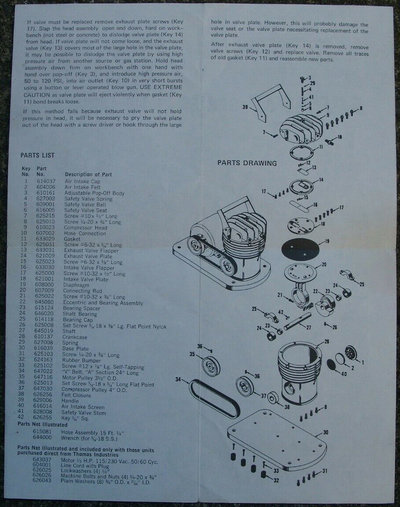

Perhaps it's not a reed valve, it's just two thin strips of stainless steel covering vent holes held down with small pozi screws...

and there are two sets of two.

Strange, from your description they sound like the valve plate inlet and exhaust reeds!

Wendelspanswick

Member

- Messages

- 6,486

It is the inlet and exhaust valves you are looking at. I still have my old Burgess compressor that I used to spray my Mini that I had 30 years ago. The reed valves either get gummed up or lose their flex, you can replace them with whatever you have to hand. I think I used an old set of feeler gauges to replace mine.

It should cope with bicycle tyres no problem. If you use the compressor with a spray gun you need a constant bleed gun or an adaptor with a tiny bleed hole otherwise you will stall the motor.

There is no pressure switch or regulator on these, it just constantly pushes out air.

It's a handy thing to have as it can be carried one handed. When my brother bought his first house he sprayed the whole interior with Magnolia emulsion using my compressor, he masked the windows, removed the electrical faceplates and just sprayed everything. Did it all in a day and made a good job of it, for some reason it always reminds me of the Mr Bean sketch when he paints his room with a pot of paint and a firework!

It should cope with bicycle tyres no problem. If you use the compressor with a spray gun you need a constant bleed gun or an adaptor with a tiny bleed hole otherwise you will stall the motor.

There is no pressure switch or regulator on these, it just constantly pushes out air.

It's a handy thing to have as it can be carried one handed. When my brother bought his first house he sprayed the whole interior with Magnolia emulsion using my compressor, he masked the windows, removed the electrical faceplates and just sprayed everything. Did it all in a day and made a good job of it, for some reason it always reminds me of the Mr Bean sketch when he paints his room with a pot of paint and a firework!

Hi

I was recently having a clear-out in my workshop and came across this very same model hidden away under my snooker table. I stumbled on this thread whilst googling details of the Burgess range of spray equipment.

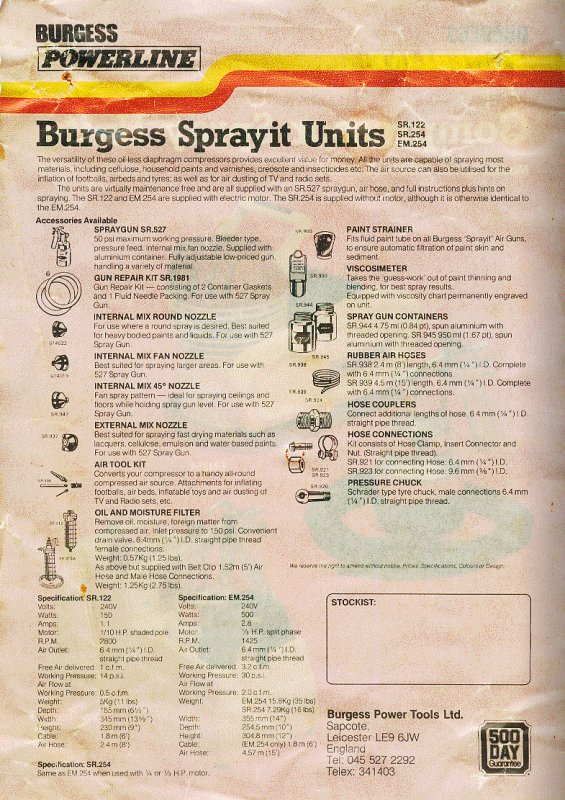

The model is actually the EM 254 and the instruction manual gives very little information about the compressor motor in its 16 pages.

Considering its vintage, it is in very good nick and working fine. Next step is an insertion on ebay

If the OP requires scans of the manual please email me.

I was recently having a clear-out in my workshop and came across this very same model hidden away under my snooker table. I stumbled on this thread whilst googling details of the Burgess range of spray equipment.

The model is actually the EM 254 and the instruction manual gives very little information about the compressor motor in its 16 pages.

Considering its vintage, it is in very good nick and working fine. Next step is an insertion on ebay

If the OP requires scans of the manual please email me.

Spanthefestaman

Member

- Messages

- 61

- Location

- Northants UK

To bring back an old thread, I have recently brought one of these just the compressor unit and not realised that it requires a specific spray gun to work correctly. So i have done some looking around and found this:

G 1/4 inch Brass Adjustable Safety Valve 1-4 bar (14.50-58.02 psi) | tameson.co.uk

My plan is that this will be able to vent of the air pressure built up by the compressor while sat on idle (spray gun trigger not pulled on a non bleeder spray gun). Failing this i saw some material on Apollo turbine sprayers and some of there early models used bleeder type spray guns but now they use non bleeder type. To overcome this on the older units so they can use the newer type guns they simply supply a fitting that screws onto the machine before the air hose with a 3/16th hole in it:

https://thefinishingstore.com/products/name?_pos=1&_sid=fe9989821&_ss=r

Looking at the previously posted instructions it says it used a 1/4 ID air hose, is this bore of hose still available and was such a small bore used to help with overall pressure?

Looing again at the instructions it says the working pressure is 30psi, is that the maximum pressure the unit can produce or the maximum it will produce while in use i.e spraying or using a blow gun? I see that the original gun was rated at 50psi max.

I only brought it using money I gained selling other junk on ebay so if it does not do what i want it to i will move it on.

G 1/4 inch Brass Adjustable Safety Valve 1-4 bar (14.50-58.02 psi) | tameson.co.uk

My plan is that this will be able to vent of the air pressure built up by the compressor while sat on idle (spray gun trigger not pulled on a non bleeder spray gun). Failing this i saw some material on Apollo turbine sprayers and some of there early models used bleeder type spray guns but now they use non bleeder type. To overcome this on the older units so they can use the newer type guns they simply supply a fitting that screws onto the machine before the air hose with a 3/16th hole in it:

https://thefinishingstore.com/products/name?_pos=1&_sid=fe9989821&_ss=r

Looking at the previously posted instructions it says it used a 1/4 ID air hose, is this bore of hose still available and was such a small bore used to help with overall pressure?

Looing again at the instructions it says the working pressure is 30psi, is that the maximum pressure the unit can produce or the maximum it will produce while in use i.e spraying or using a blow gun? I see that the original gun was rated at 50psi max.

I only brought it using money I gained selling other junk on ebay so if it does not do what i want it to i will move it on.

Spanthefestaman

Member

- Messages

- 61

- Location

- Northants UK

So the little brass fitting in the cylinder head is a relief valve which blows at 50psi and relieves pressure back to roughly 30psi. It is quite a harsh release so I'm still going to get the valve I mentioned. I've now picked up my mini gun and gun gauge so I can test working pressure better. Hope this info helps anyone who has one of these! I think the biggest issue will be CFM but I will see.

Overall I'm happy with the unit I got it runs quiet apart from rattly belt cover and is in good nick. Would look good in the garage as a piece of retro tooling if nothing else!

Overall I'm happy with the unit I got it runs quiet apart from rattly belt cover and is in good nick. Would look good in the garage as a piece of retro tooling if nothing else!

Spanthefestaman

Member

- Messages

- 61

- Location

- Northants UK

Does anyone know what the little oiler flap things are for on the motor? Grease or oil?

brightspark

Member

- Messages

- 40,167

- Location

- yarm stockton on tees

will be oil. the bearings are bronze in the motor and have felt washers at the sides dont over do it just a few drops will do

pietjeleon

New Member

- Messages

- 1

- Location

- netherlands

Spanthefestaman

Member

- Messages

- 61

- Location

- Northants UK

That's a brilliant bit bit of information kind of confirms a few things. If i could get 40psi from my unit I should be able to run my mini gun. Trouble is I only seem to be getting 30psi. I don't really want to take the valve plate that is in the head out as I don't want to damage the gasket. I will have another play with it when I get a minute. Just busy fixing my car as it went through a flood and has suffered for it.

Spanthefestaman

Member

- Messages

- 61

- Location

- Northants UK

Would you think trying to measure the pressure with a gauge will effect the overall pressure?