You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cebora/Snapon/BOC 130 Euro torch conversion

- Thread starter rikrobson

- Start date

The Eurosocket assembly for sale that I linked to has the circular threaded brass block, with connections for gas, welding current, MIG wire, and trigger wires. You are right in that the familiar black plastic shroud is not supplied. However, I think that is just an insulating ring, with no actual mechanical function? Any suitable plastic pipe or ring would do, or even just a layer of tape. As long as the hole through the original metal front panel was large enough to provide clearance, you wouldn't actually need anything, just the brass block sticking through.....

Yes, you are quite right, that black ring does help to support the very long Euro plug, and it also transfers the weight of the heavy torch umbilical.

If you cannot obtain the correct part, you could just fit a 100mm square plate of some 12mm thick insulating material ( even plywood ) to the front of the welder case, with a 42mm hole for the collar of the torch securing nut.

If you cannot obtain the correct part, you could just fit a 100mm square plate of some 12mm thick insulating material ( even plywood ) to the front of the welder case, with a 42mm hole for the collar of the torch securing nut.

If anyone replaces their cheap plastic wirefeed assembly with a decent all-metal one, it should be noted that the whole assembly is "live" and will need to be isolated from the metal case of the welder. This is often done with shouldered nylon washers for the mounting screws, which may or may not be supplied with the new unit.

In the case of the UK-sourced one I linked to above, the assembly is already mounted on a handy black plastic plinth.

In the case of the UK-sourced one I linked to above, the assembly is already mounted on a handy black plastic plinth.

Hi all,

I have followed the instructions above and fitted the euro torch conversion. Thanks to the OP for the clear instructions, made it very easy!

In addition to the euro torch I plan on using a spool welder which requires an additional 12v input to power the motor. Does anyone know where I can find a 12v supply to feed off?

Worst case I can run off the main motor supply and isolate the internal wire feed with a switch but I would rather avoid that if possible.

Thanks

Michael.

I have followed the instructions above and fitted the euro torch conversion. Thanks to the OP for the clear instructions, made it very easy!

In addition to the euro torch I plan on using a spool welder which requires an additional 12v input to power the motor. Does anyone know where I can find a 12v supply to feed off?

Worst case I can run off the main motor supply and isolate the internal wire feed with a switch but I would rather avoid that if possible.

Thanks

Michael.

Have you tried it yet ?

I haven't tried welding with it yet. So far I've only carried out checks to see If the solenoid valve and motor feed were working on the standard euro torch.

I took another feed off the motor wire line to feed the spool gun but this meant the spool gun and internal wire feed were running at the same time. I should have guessed that to be fair. Rookie error.

I'm not planning on testing the welding until I am happy with the wiring, then I can "borrow" some argon from the tig at work to check the spool gun works before spending money on a bottle of gas.

That will be interesting as ive a cebora myself and a spare 4 m torch lurking.It will be interesting to see what youve done

Interesting is a good word for it!

I bought a non working sipmate eurotorch conversion for £60. The seller had fitted a 4m torch. I wasn't sure if it was the sipmate or the 4m hose causing the issue, but I have fitted those parts to my cebora with a 3m torch. I have the 4m torch to compare against once everything is working.

untakenname

New Member

- Messages

- 1

- Location

- London

Was inspired by this thread as I've got an old Snapon that had a damaged wirefeed and also the torch had seen better days so it made economic sense to convert rather than buy a new system.

Ended up buying what was linked above on ebay, the motor is a lot beefier than the Cebora.

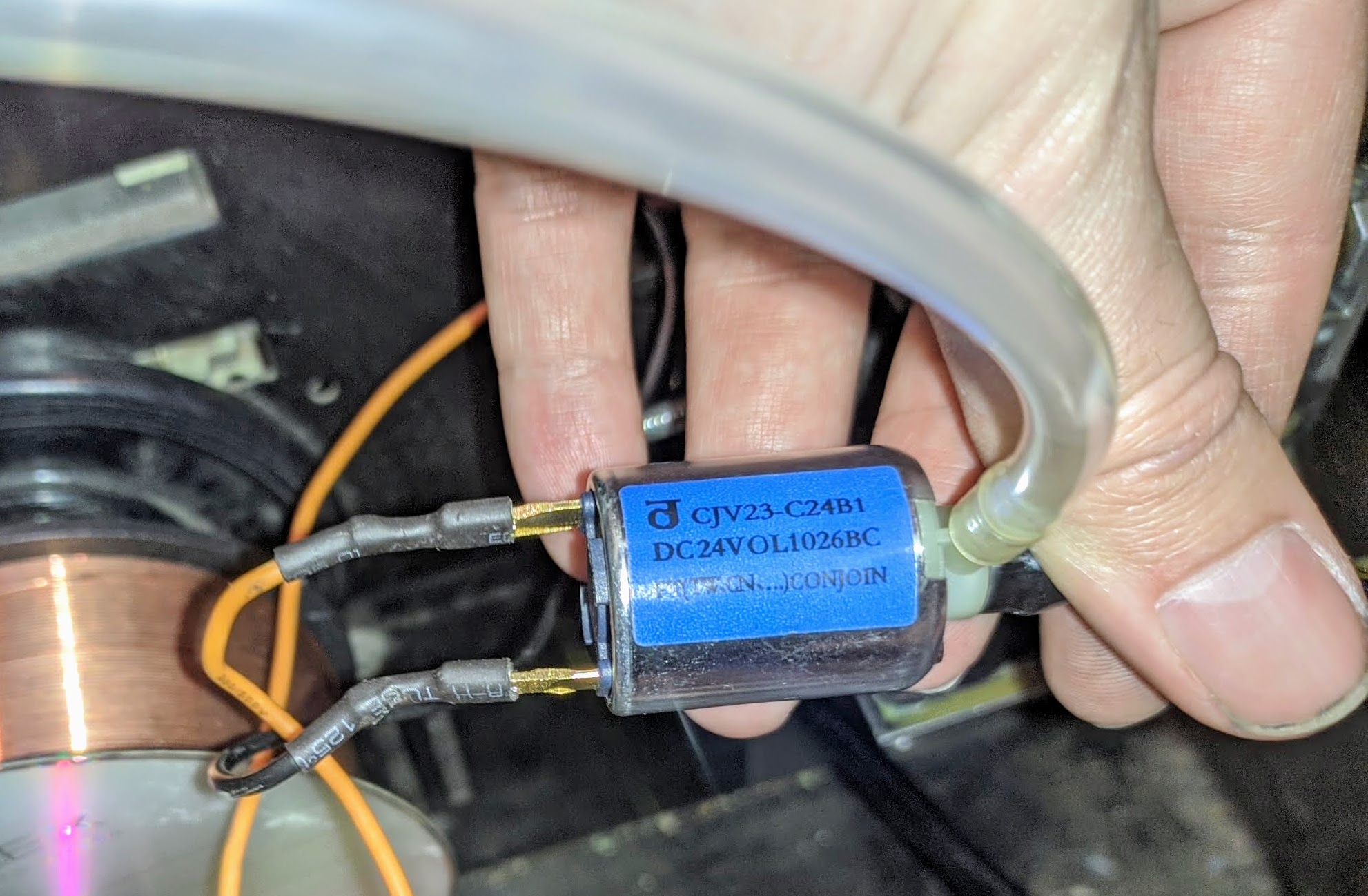

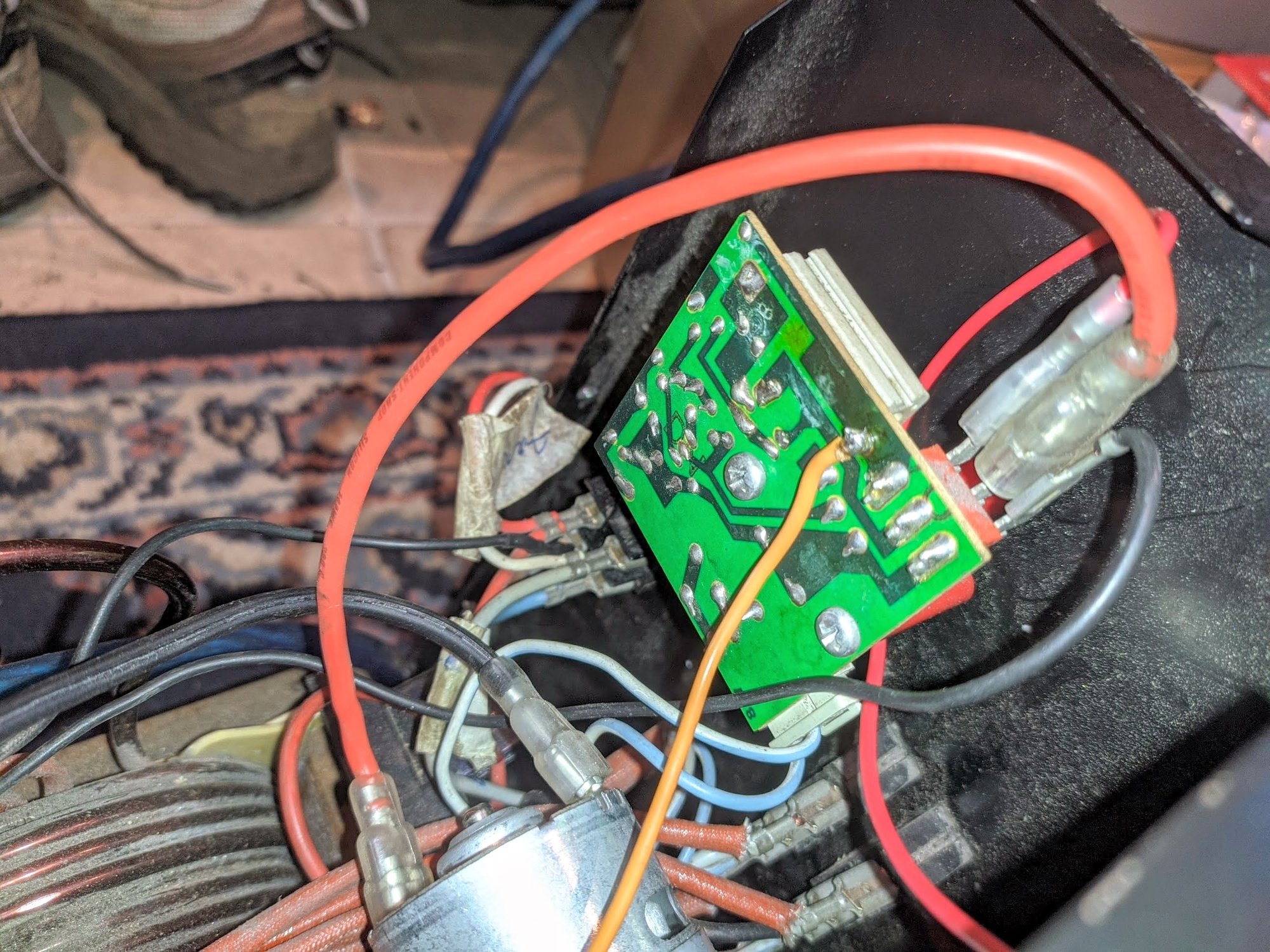

Bought a £3 24v Chinese solenoid and connected it to the PCB where it gets from 22-26V depending on what setting is used, I initially wired it in parallel with the motor but it only activated at max speed, on the slower speeds it was only registering around 11v.

Not sure how long it will last for but if it does break I'll probably use an automotive solenoid as you can get them for a couple of pounds secondhand from a breaker.

Hope this is of help for anyone considering doing the same, total cost for the conversion was around £35.

Ended up buying what was linked above on ebay, the motor is a lot beefier than the Cebora.

Bought a £3 24v Chinese solenoid and connected it to the PCB where it gets from 22-26V depending on what setting is used, I initially wired it in parallel with the motor but it only activated at max speed, on the slower speeds it was only registering around 11v.

Not sure how long it will last for but if it does break I'll probably use an automotive solenoid as you can get them for a couple of pounds secondhand from a breaker.

Hope this is of help for anyone considering doing the same, total cost for the conversion was around £35.

Hello, and welcome to the Forum !

Your Eurotorch conversion looks great. It seems that you used some laminated UPVC as an insulating mounting for the wirefeed assembly, and also as a shroud on the threaded brass block and the hole in the front panel of the welder ?

Don't forget to turn the gas off at the cylinder when you finish welding - I'm not sure I would trust that solenoid to shut off fully.

You said "but if it does break I'll probably use an automotive solenoid " - what would the original use of an automotive solenoid be?

Your Eurotorch conversion looks great. It seems that you used some laminated UPVC as an insulating mounting for the wirefeed assembly, and also as a shroud on the threaded brass block and the hole in the front panel of the welder ?

Don't forget to turn the gas off at the cylinder when you finish welding - I'm not sure I would trust that solenoid to shut off fully.

You said "but if it does break I'll probably use an automotive solenoid " - what would the original use of an automotive solenoid be?